Lifting type wall grooving machine

A slotting machine and lift-type technology, which is applied in the field of lift-type wall slotting machines, can solve the problems of unfavorable staff working normally, high labor intensity, and low efficiency, so as to improve the quality of wall painting, improve work efficiency, and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

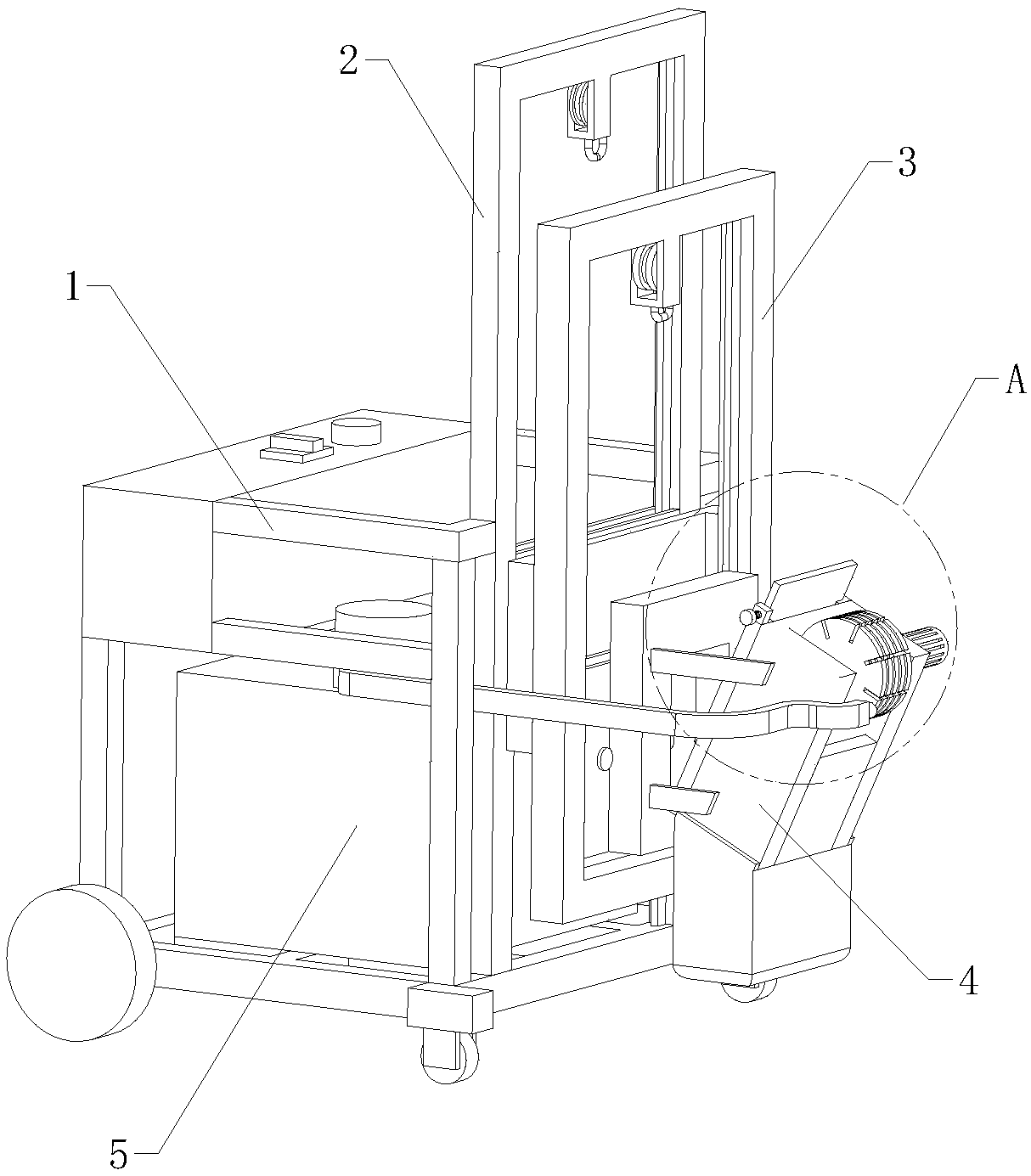

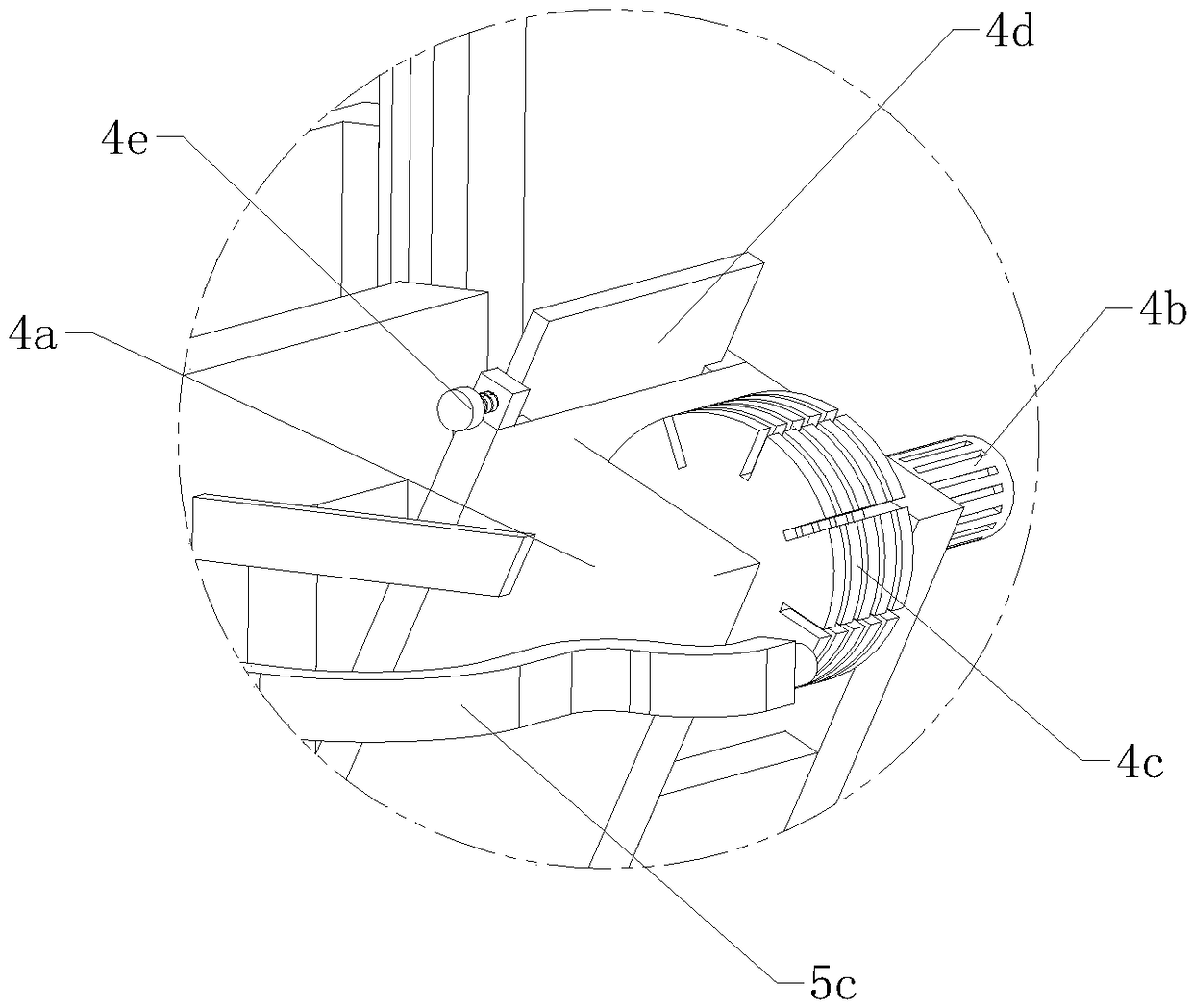

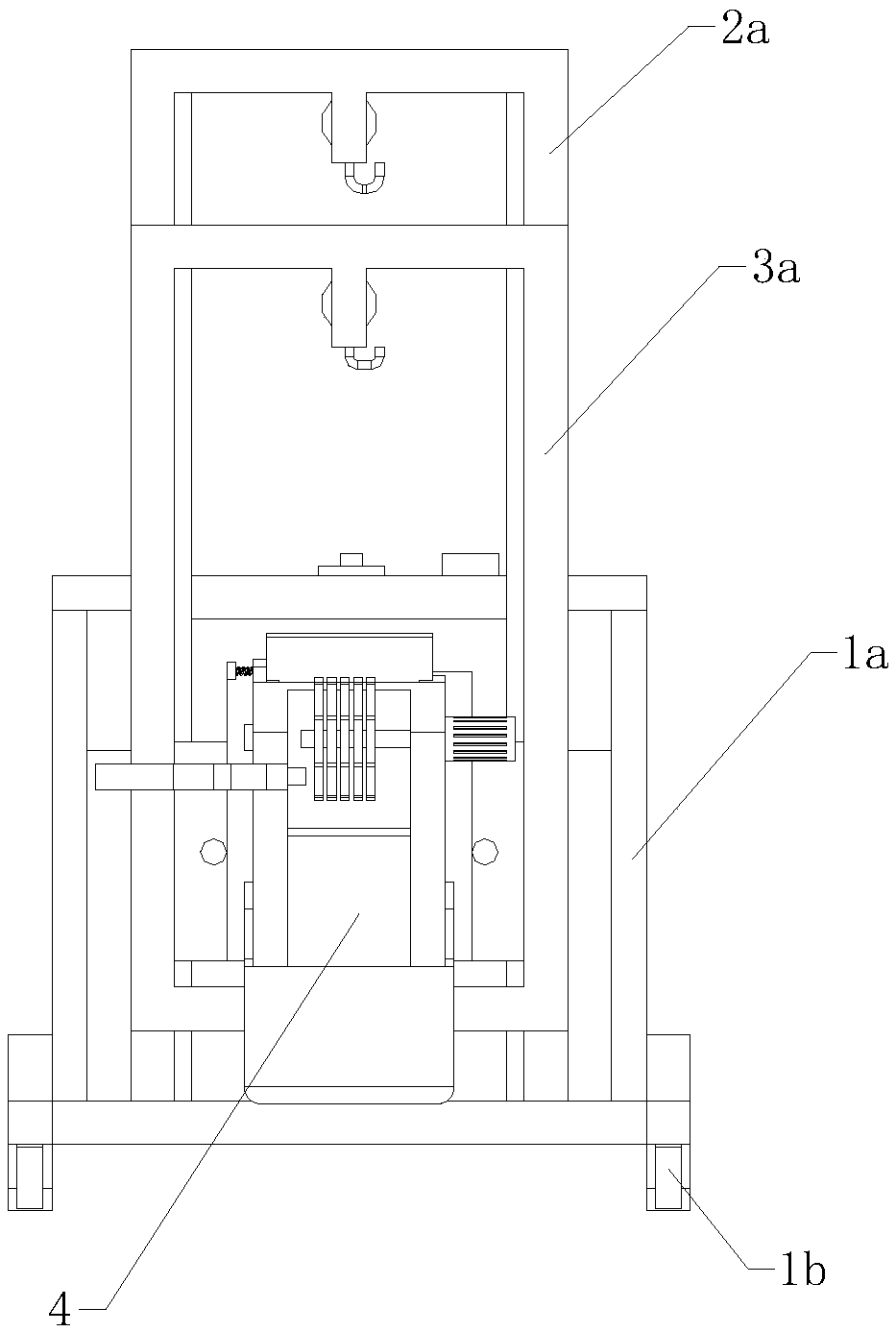

[0033] refer to Figure 1 to Figure 16A lifting type wall slotting machine shown includes a body body 1, a first lifting frame 2, a second lifting frame 3, a slotting device 4 and a flushing device 5, and the body body 1 includes a vehicle frame 1a, a wheel assembly 1b and a control box 1c, the wheel assembly 1b is arranged under the vehicle frame 1a, the control box 1c is arranged on the vehicle frame 1a, the first lifting frame 2 is a rectangular frame structure, and the first lifting frame 2 includes There are a first fixed frame 2a, a first pulley block and a first movable plate 2c, the first fixed frame 2a is arranged in front of the vehicle frame 1a, the first pulley block is arranged on the first fixed frame 2a, and the first movable plate The plate 2c is arranged on the first fixed frame 2a, the first pulle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com