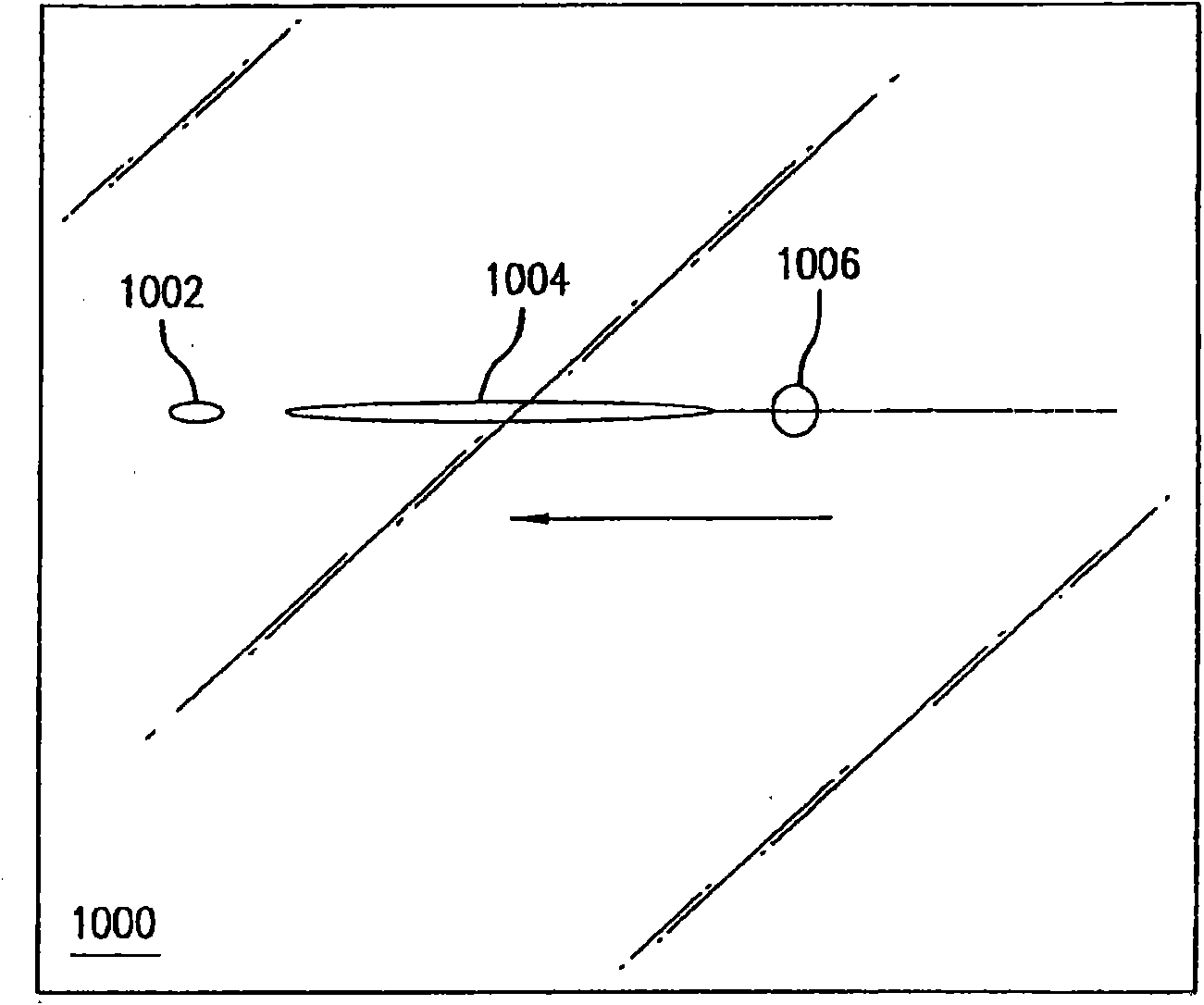

Scoring of non-flat materials

A technology of laser beams and beams, applied in the direction of instruments, manufacturing tools, glass manufacturing equipment, etc., can solve problems such as high cost and complicated technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0048] To further illustrate the principles of the invention, the following examples are provided to provide those of ordinary skill in the art with a complete illustration and description of the systems and methods and evaluations that constitute the claims herein. These examples are provided only to illustrate the present invention, and are not intended to limit the scope of what the inventors regard as their invention. Efforts have been made to ensure accuracy with respect to numbers (eg, amounts, temperature, etc.); however, some errors and deviations may have occurred.

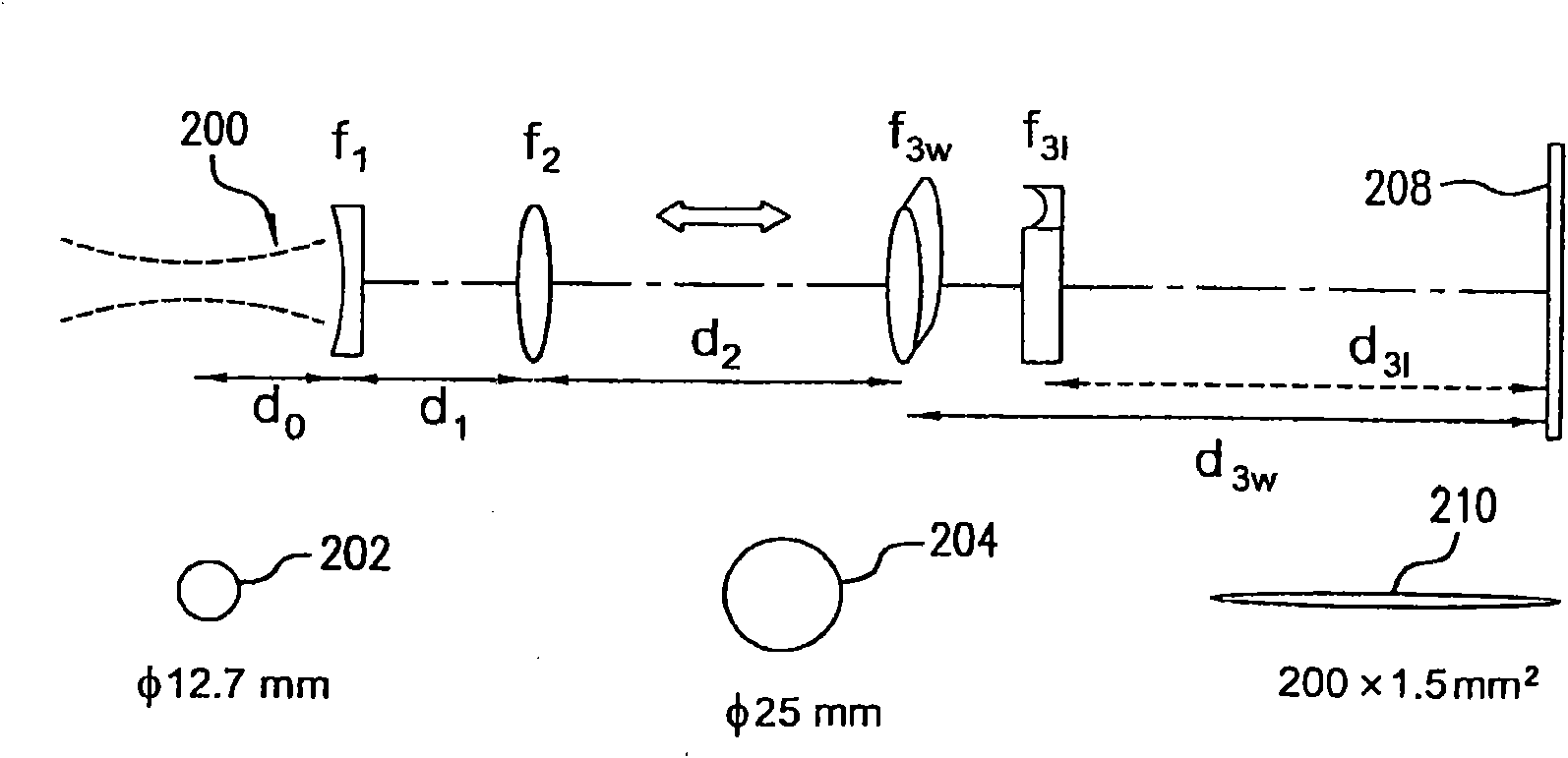

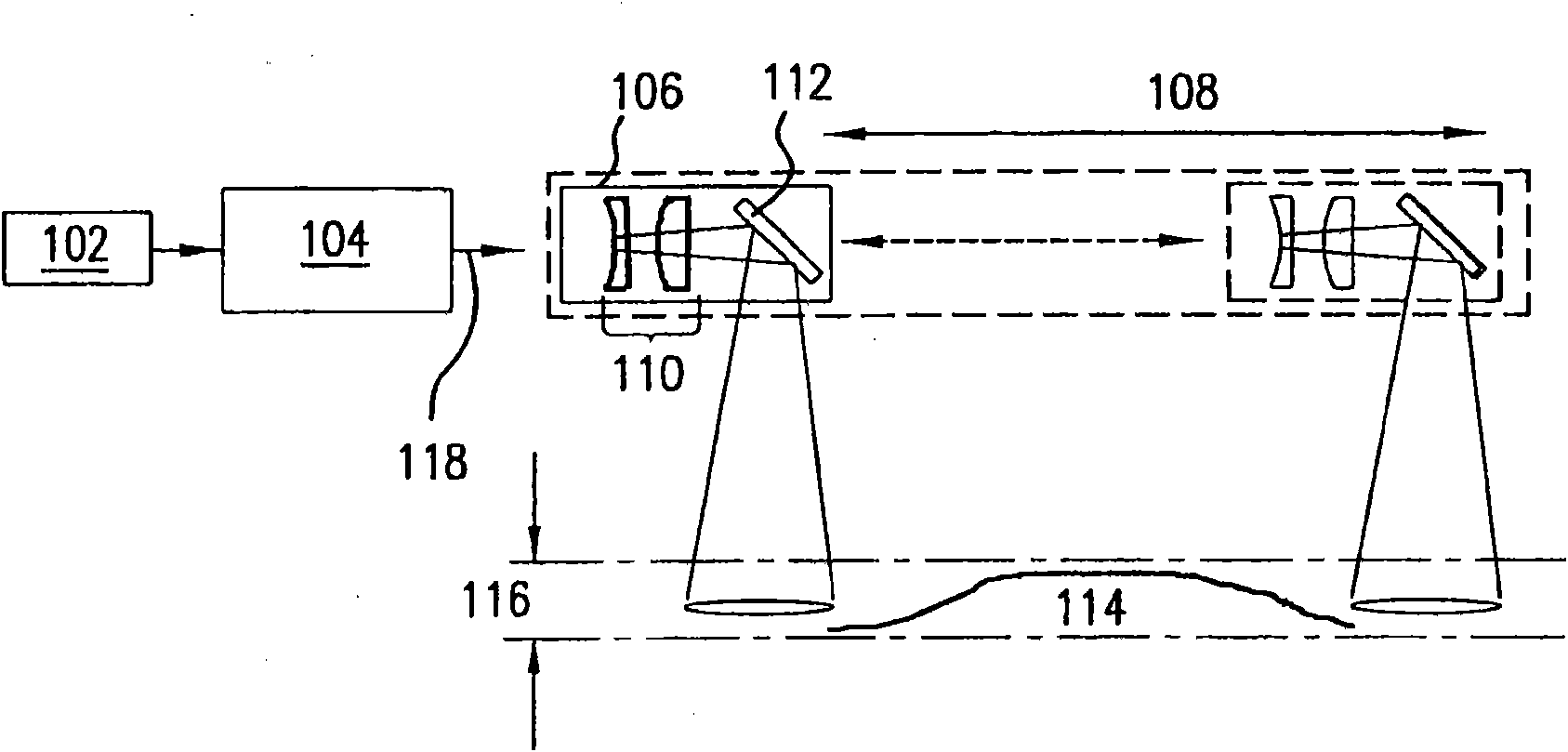

[0049] As noted above, the stationary components of the beam delivery system (including, in one embodiment, the laser and the beam expander) maintain a substantially constant laser beam characteristic over the flight distance. In one aspect, the optical system can be configured for a standard Gaussian laser mode, referred to as TEM00 mode, also known as the so-called D-mode. D-mode is a 60 / 40 mix of TEM0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com