Junction formation on wafer substrates using group IV nanoparticles

A nanoparticle and wafer technology, applied in the field of nanoparticles, can solve the problems of limited manufacturing throughput, lack of simultaneous patterning, and constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

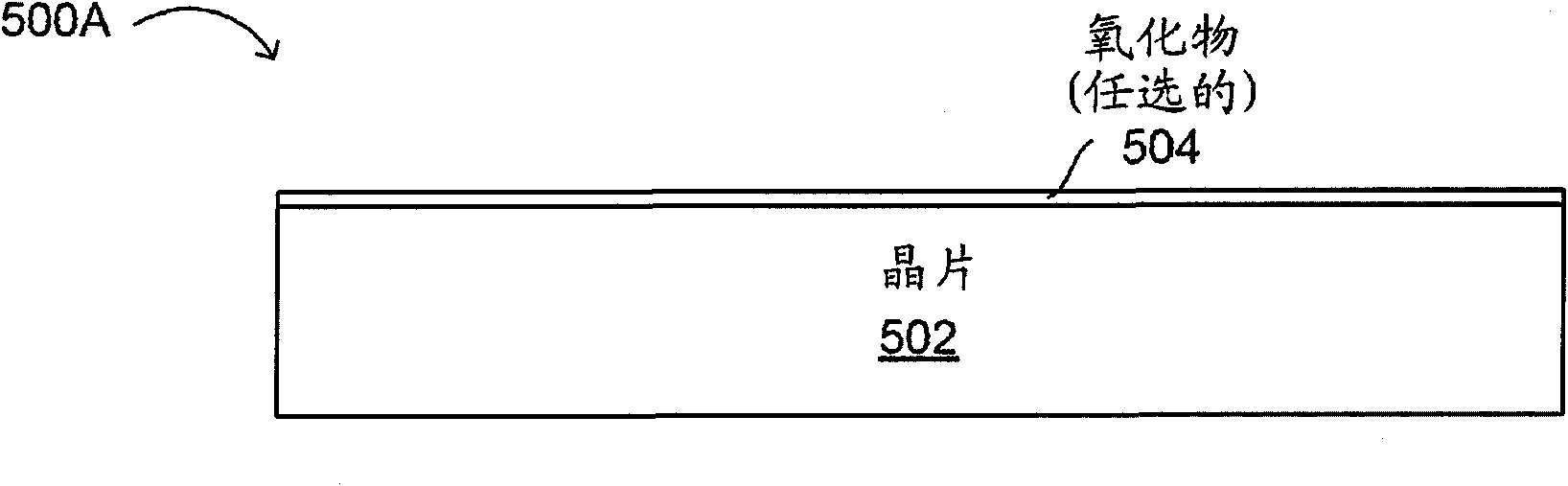

[0074]In this example, a 1 inch x 1 inch x 0.019 inch silicon wafer substrate doped with phosphorus to a resistivity of about 1 to 5 Ohmxcm was prepared by etching with NaOH, SC2, buffered oxide etch (BOE), and Piranha's Handle for cleaning.

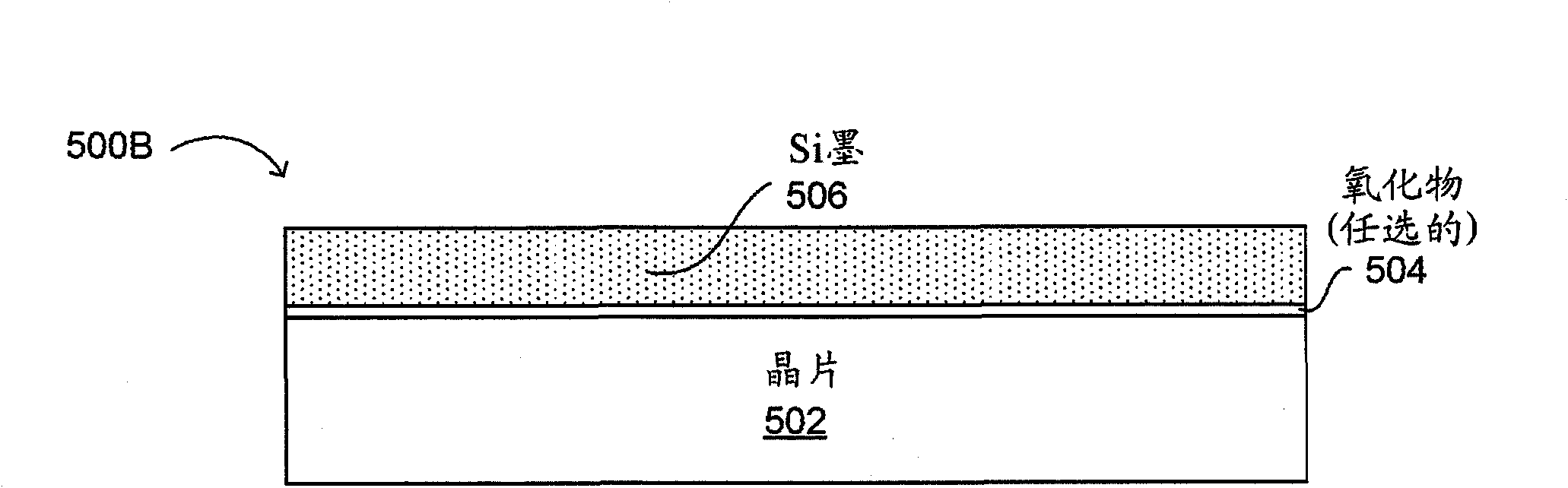

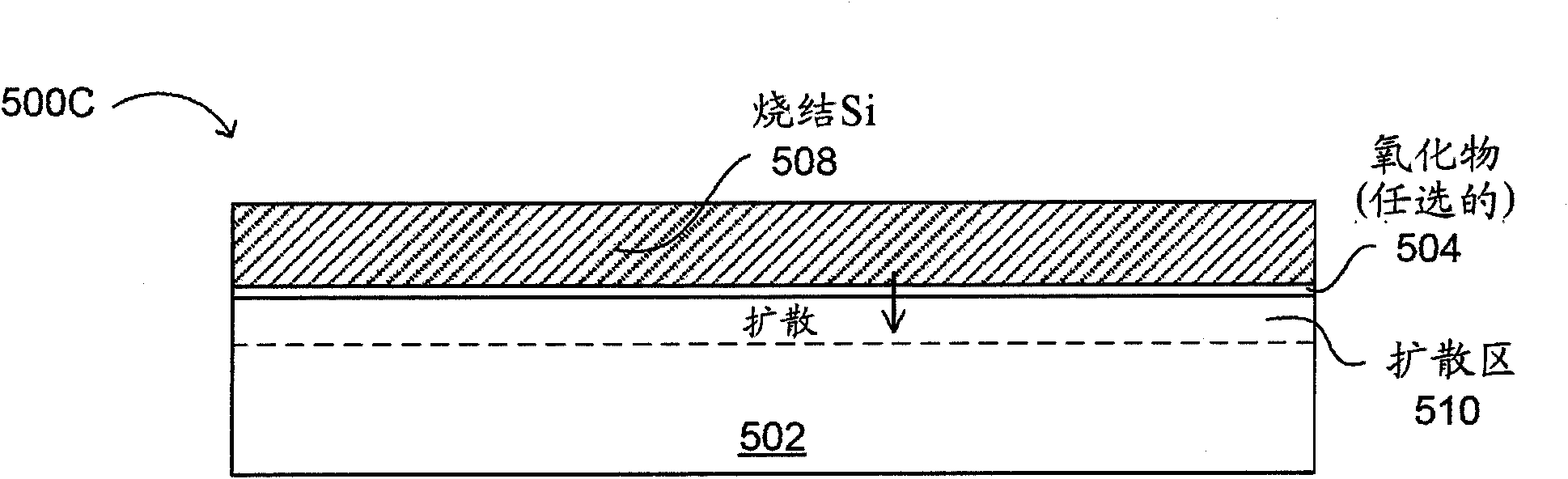

[0075] Additionally, a p-type silicon nanoparticle ink was prepared from approximately 10.0 nm + / - 0.5 nm silicon nanoparticles in an inert environment as a solution in pyridine at 5 mg / ml using a 15% power sonicated horn Sonicate it for 15 minutes. A sufficient amount of silicon nanoparticle ink was applied to substantially cover the wafer surface and spin-coated at 1000 rpm for 60 seconds to form a silicon nanoparticle porous dense body. After baking the layer on a hot plate at 100°C for 30 minutes in an inert environment, it was spin-coated at 1000 rpm for 60 seconds to form a second silicon nanoparticle porous dense body, and then in an inert environment on Bake at 100°C for 30 minutes on a hot plate. The thickness of the formed s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap