Self-locking zipper head

A zipper slider and self-locking technology, applied in the field of zipper sliders, can solve the problems of complex structure, many parts, unfavorable mechanical automatic assembly, etc., and achieve the effect of simple structure and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

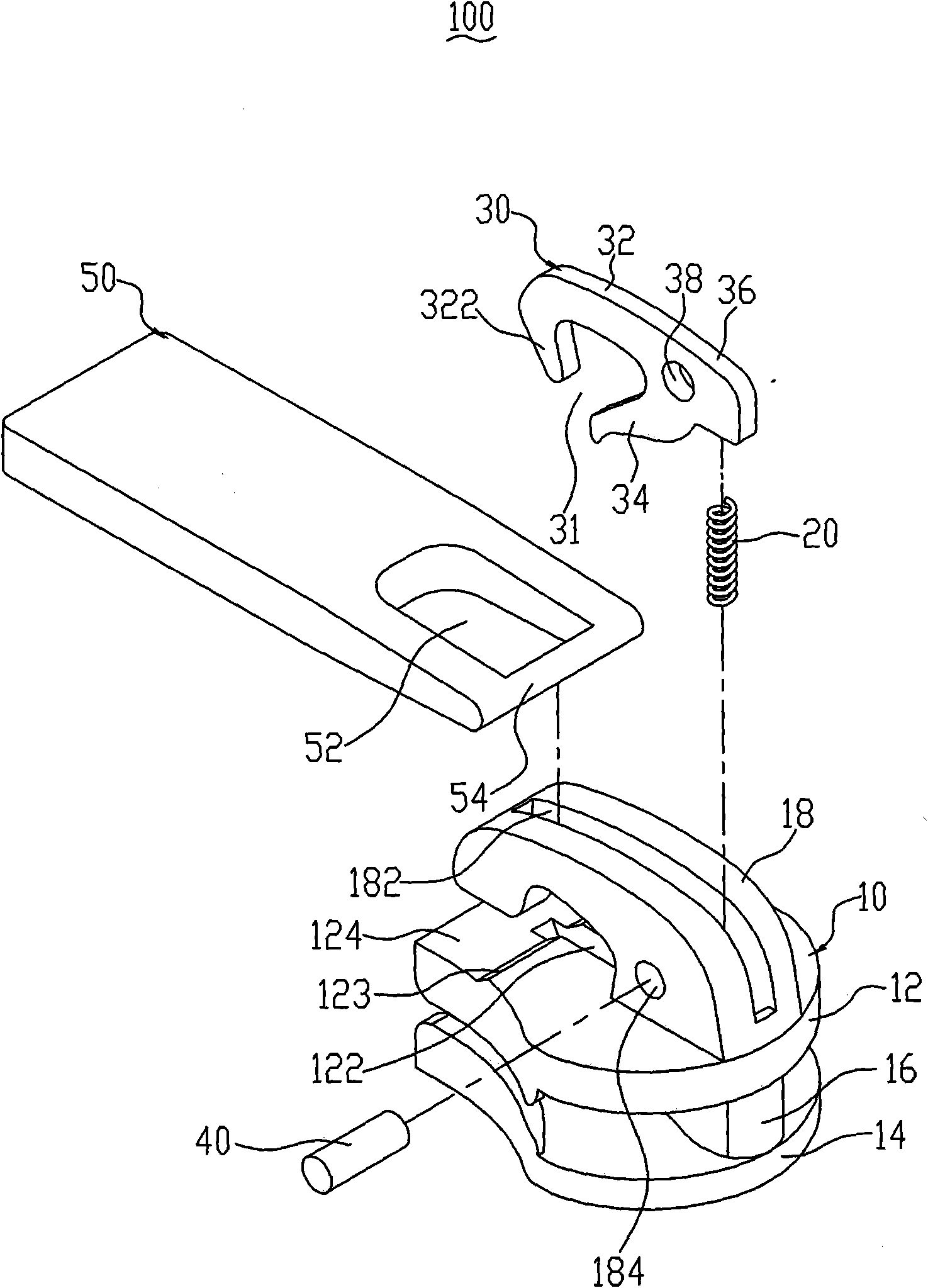

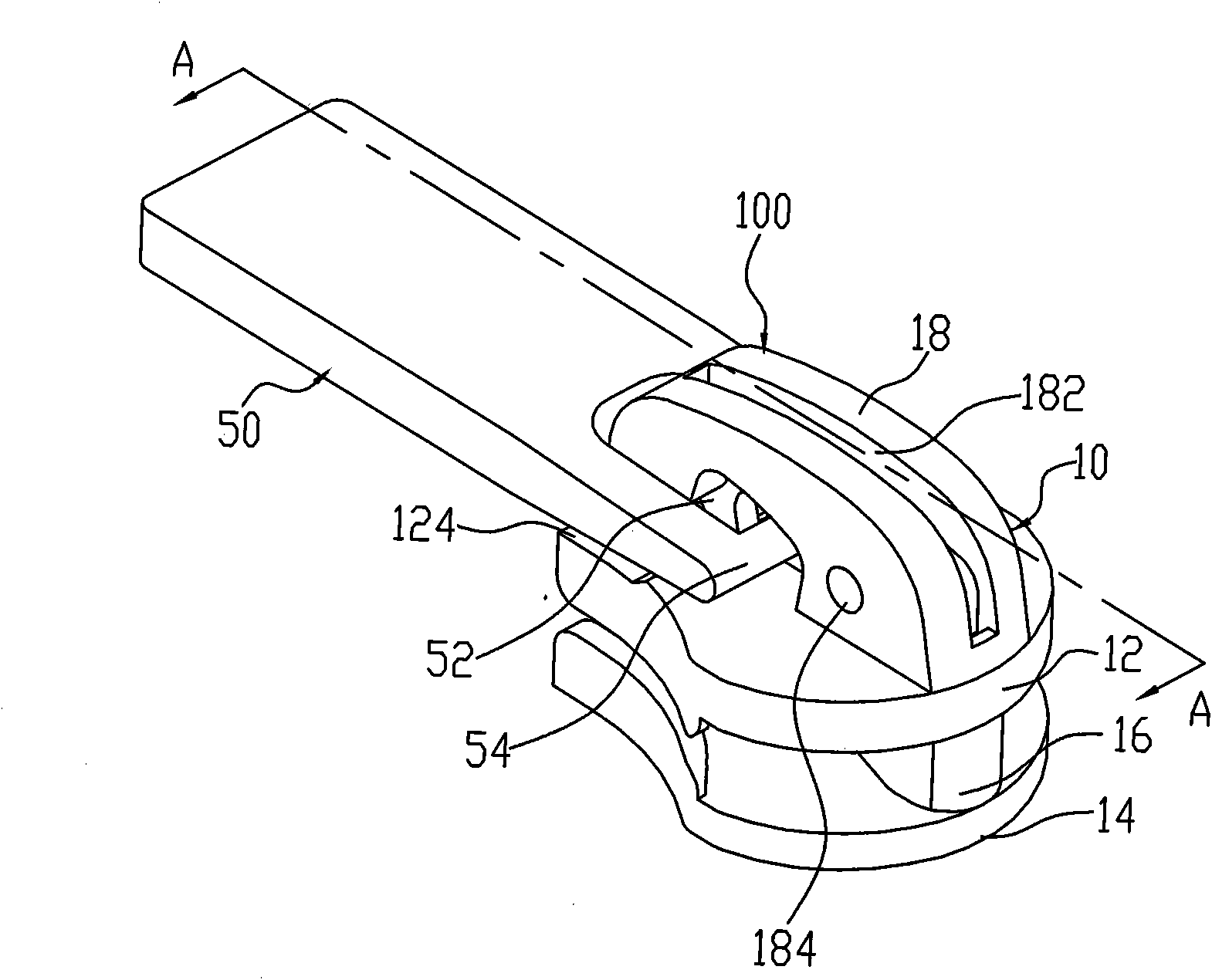

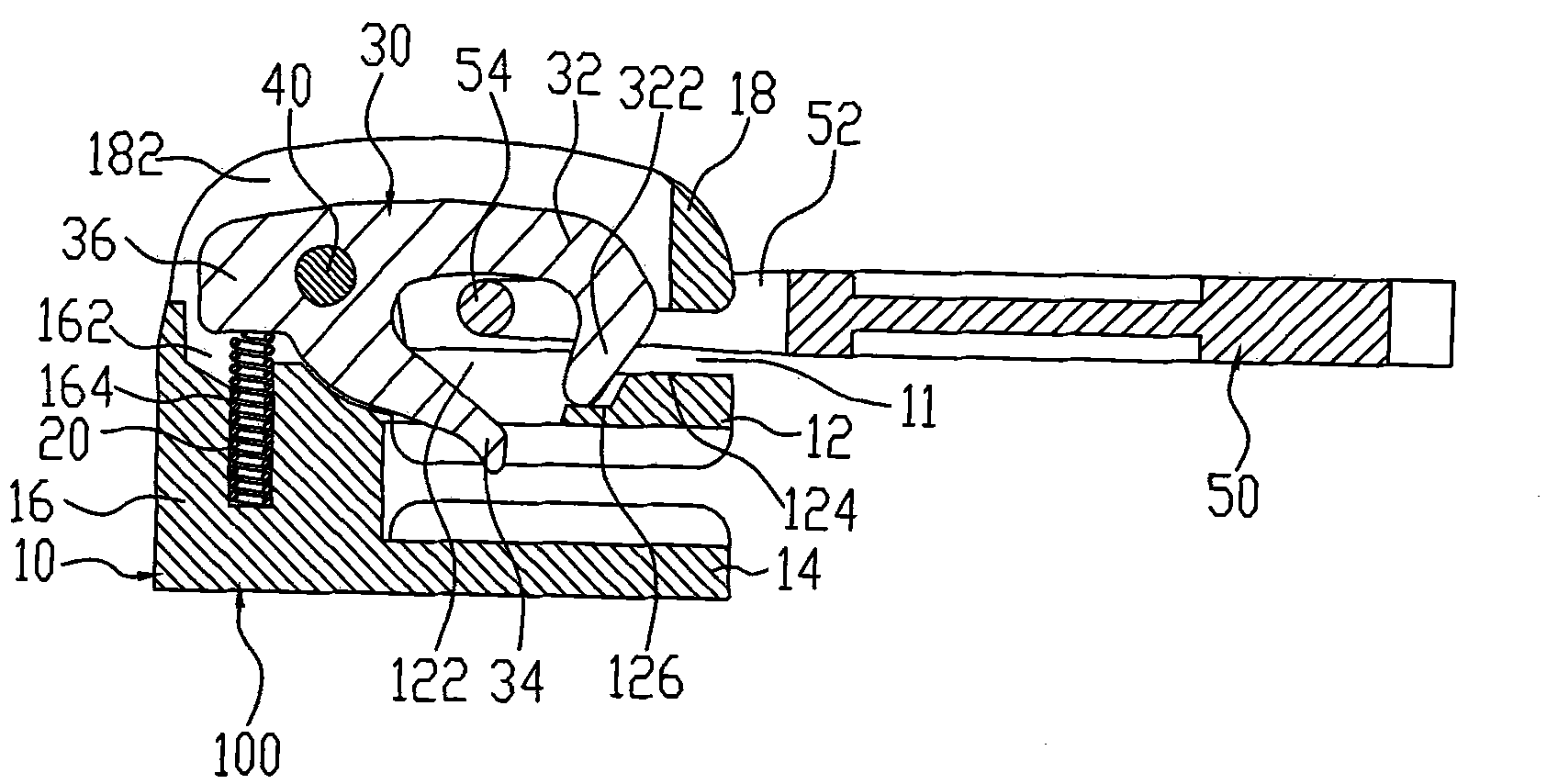

[0047] figure 1 Shown is a three-dimensional exploded view of the first embodiment of the self-locking zipper slider of the present invention. The self-locking zipper puller 100 includes a slider body 10 , a spring 20 , a self-locking element 30 , a rotating shaft 40 and a pull piece 50 . The spring 20, the self-locking element 30, the rotating shaft 40 and the handle 50 are sequentially assembled on the slider body 10 (such as figure 2 and 3 shown).

[0048] Please refer to figure 1 and image 3 , the pull piece 50 is provided with a set of holes 52 at its front, the set hole 52 and the front end of the pull piece 50 form a pull rod 54, and the outside of the pull rod 54 is arc-shaped. The self-locking element 30 is a sheet-like structure, including a buckle portion 32, a horse hook portion 34 and an abutment portion 36, the buckle portion 32 is located at the rear end of the self-locking element 30, the abutment portion 36 Located at the front end of the self-locking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com