Scissor lifting device

A technology of lifting device and scissors, which is applied in the direction of lifting device, lifting frame, etc., can solve the problem of high initial pressure of the hydraulic system, achieve the effect of increasing the lifting weight and expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

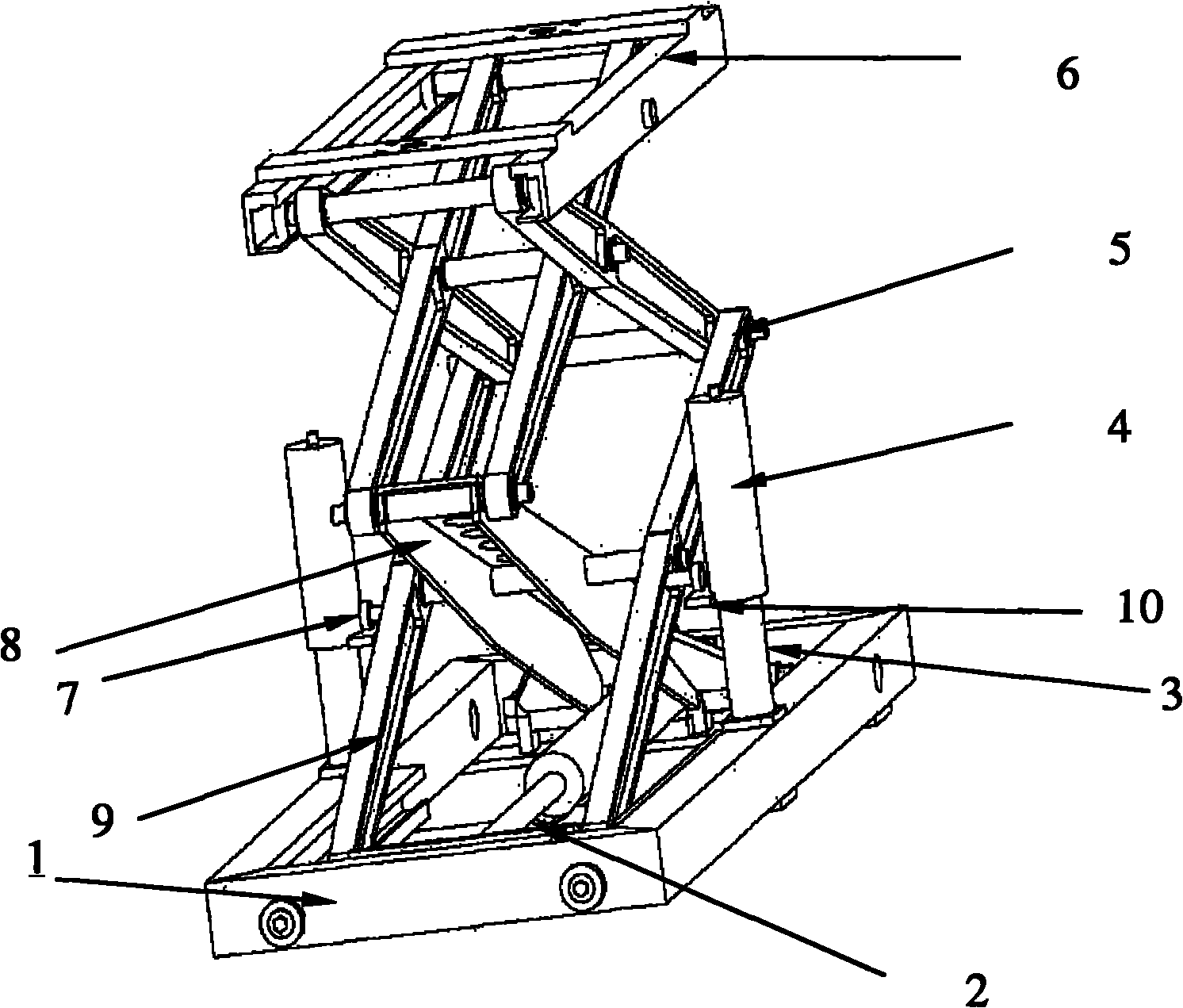

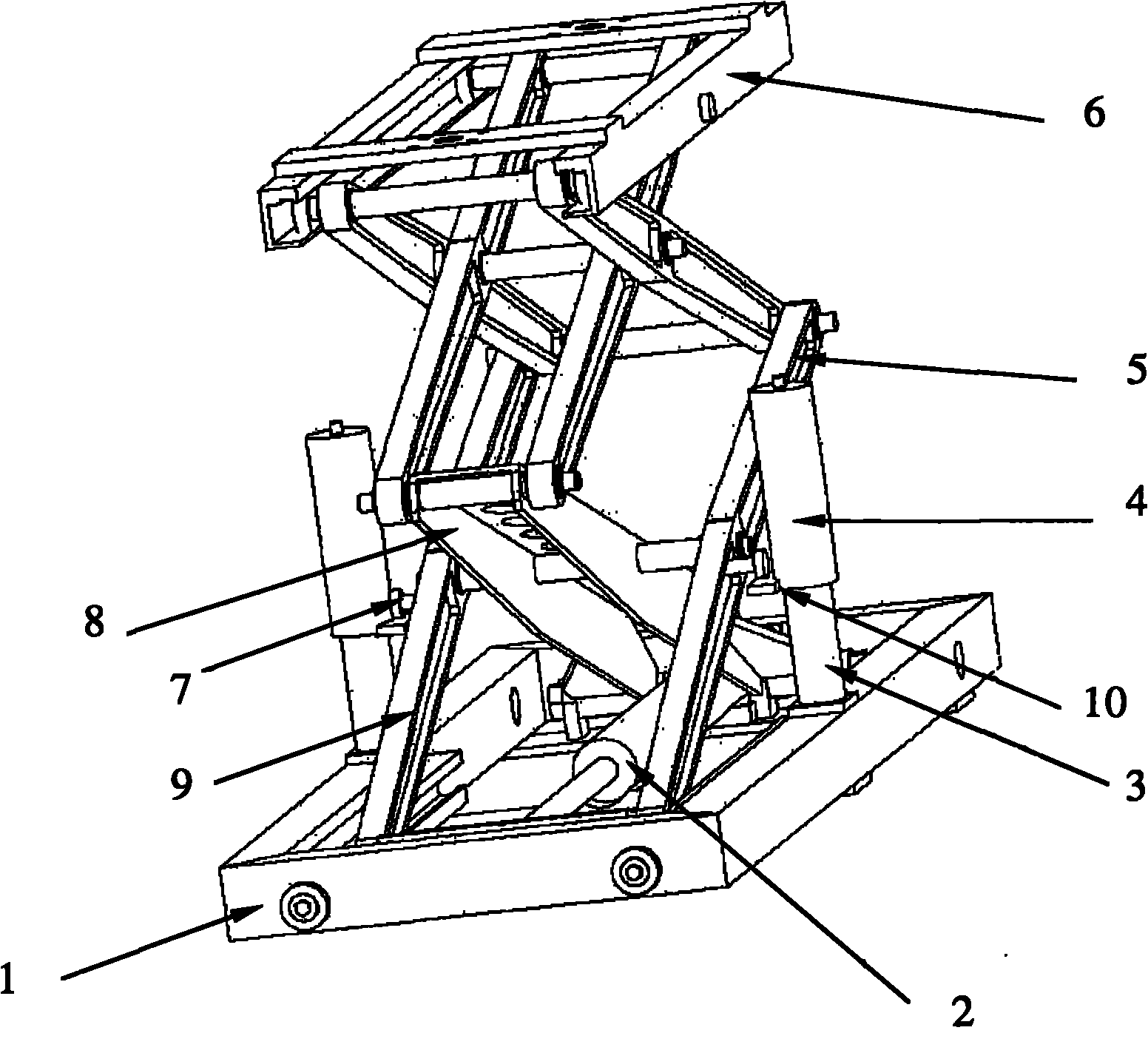

[0027] In this embodiment, the scissor lift device includes a base 1 , a scissor lift mechanism disposed on the base 1 , a hydraulic master cylinder 2 and a lifting mechanism.

[0028] Such as figure 1 As shown, the hydraulic master cylinder 2 is horizontally placed on the base 1 . The scissor lift mechanism includes two groups of lifting brackets connected in a scissor shape and a workbench 6 arranged on the top of the two groups of lifting brackets, and each group of lifting brackets consists of a plurality of lifting brackets. The rods 5 are hinged sequentially. Among the above-mentioned two groups of multiple lifting struts, the lifting struts of each layer are hinged together in pairs in a scissors-like shape. The lowermost lifting strut in one group of lifting brackets is the first lifting strut 8, and the bottom end of the first lifting strut 8 is rotatably connected to the base 1 through a rotating shaft, and the other set of lifting brackets The lowermost lifting st...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is that the two protruding rods are respectively fixed on both sides of the workbench 6 .

[0040] Other structures and uses in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com