Straw grate-firing boiler adaptive to moisture movement

A straw layer and boiler technology, applied in the direction of solid fuel combustion, combustion method, combustion equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] There are two kinds of straw raw materials for the straw-fired boiler adapted to water changes provided by the present invention, which are straws produced at the end of November in the Panjin area of Liaoning Province. The analysis results of the basic elements of the straws are: Car=42.08, Har=7.53, Oar=38.42 , Nar=1.97, Sar=0.21, Mar=6.21, Aar=3.58, the calorific value at the low position of the applied base is 15.513MJ / Kg; the straw produced at the end of October in Panjin, Liaoning Province, the analysis result of the applied base element of the straw: Car=29.67, Har=3.91, Oar=22.87, Nar=1.52, Sar=0.09, Mar=39.15, Aar=2.79, the calorific value of the low position of the applied base is 9.633MJ / Kg.

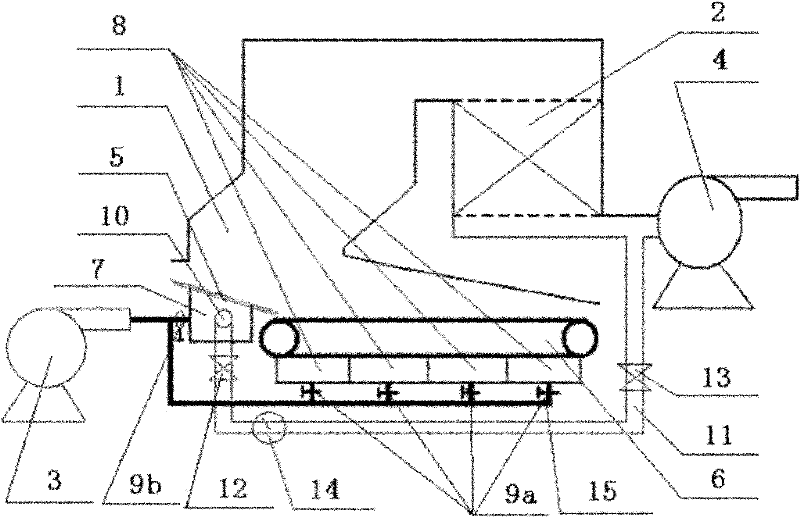

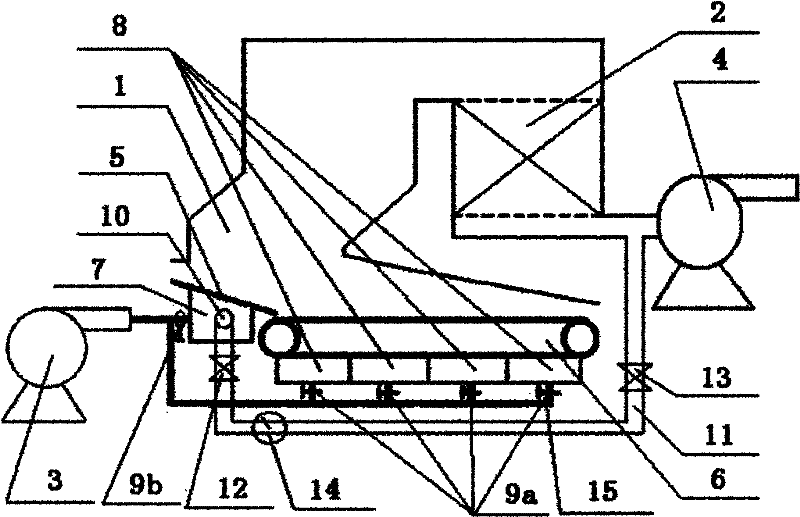

[0030]Transformation of a coal-fired 7MW hot water chain boiler. The vibrating grate is arranged at the front of the original grate position, the inclination angle of the vibrating grate is 15°, and the length of the vibrating grate is 1.5m; the other part of the orig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com