Transferring system for magnetic levitation

A technology of transmission system and magnetic force, applied in the direction of magnetic attraction or thrust holding device, electrical components, etc., can solve problems such as damaged components, noise, and generation of particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to fully understand the present invention and its advantages, reference will now be made to the accompanying drawings, which illustrate embodiments of the invention.

[0060] Hereinafter, the present invention will be described in detail by explaining embodiments of the invention with reference to the accompanying drawings. The same reference numbers in the various drawings represent the same elements.

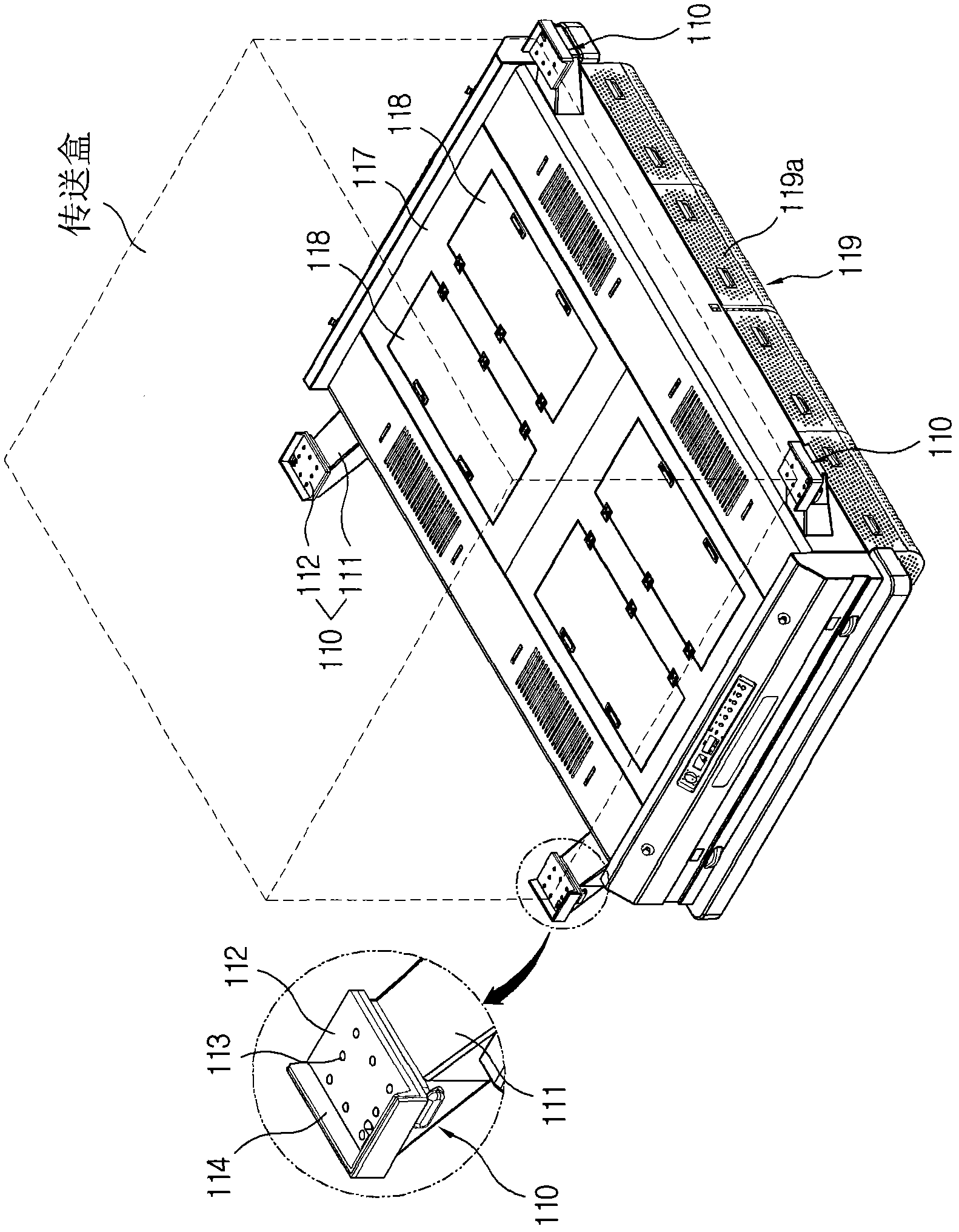

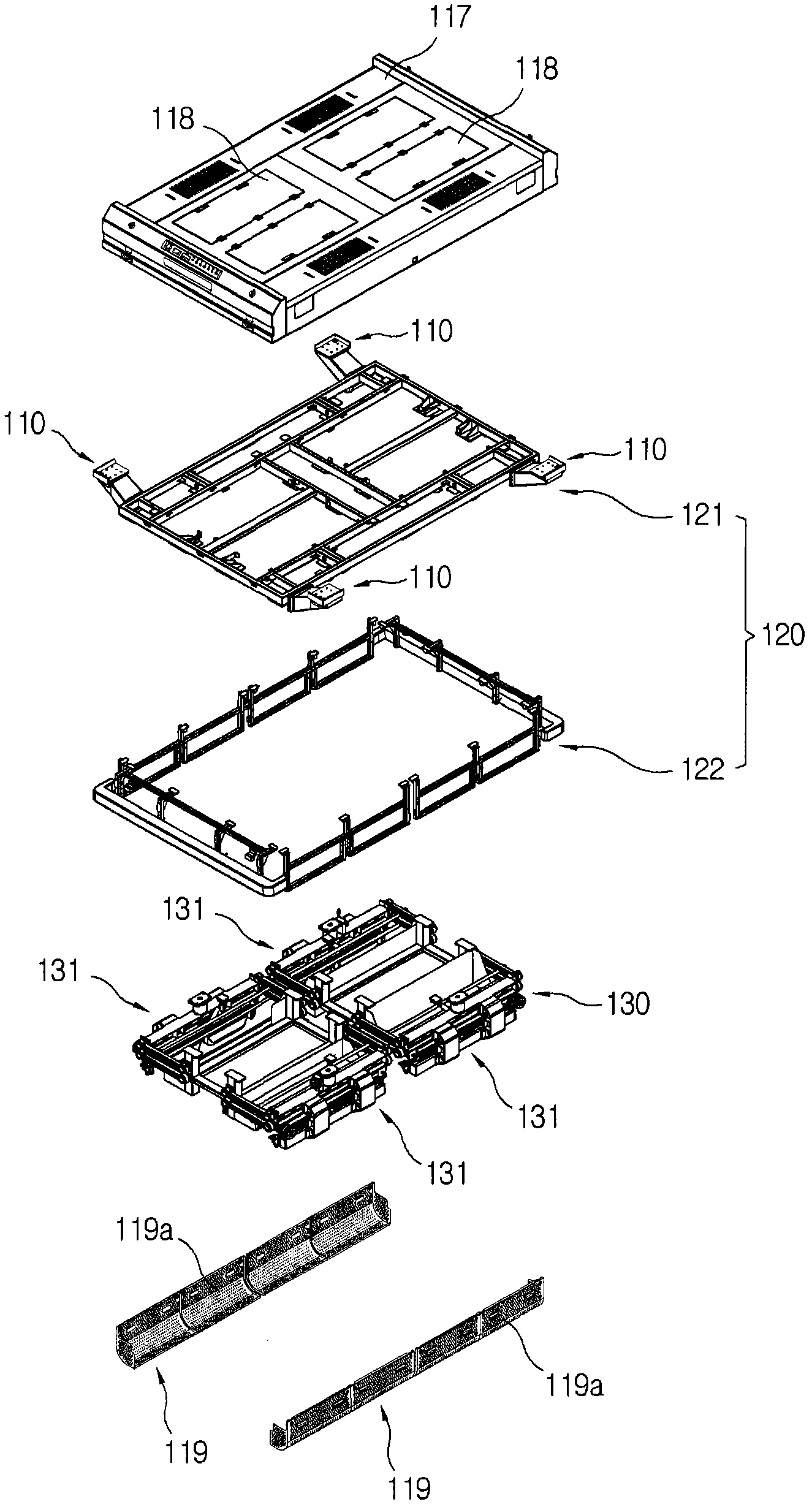

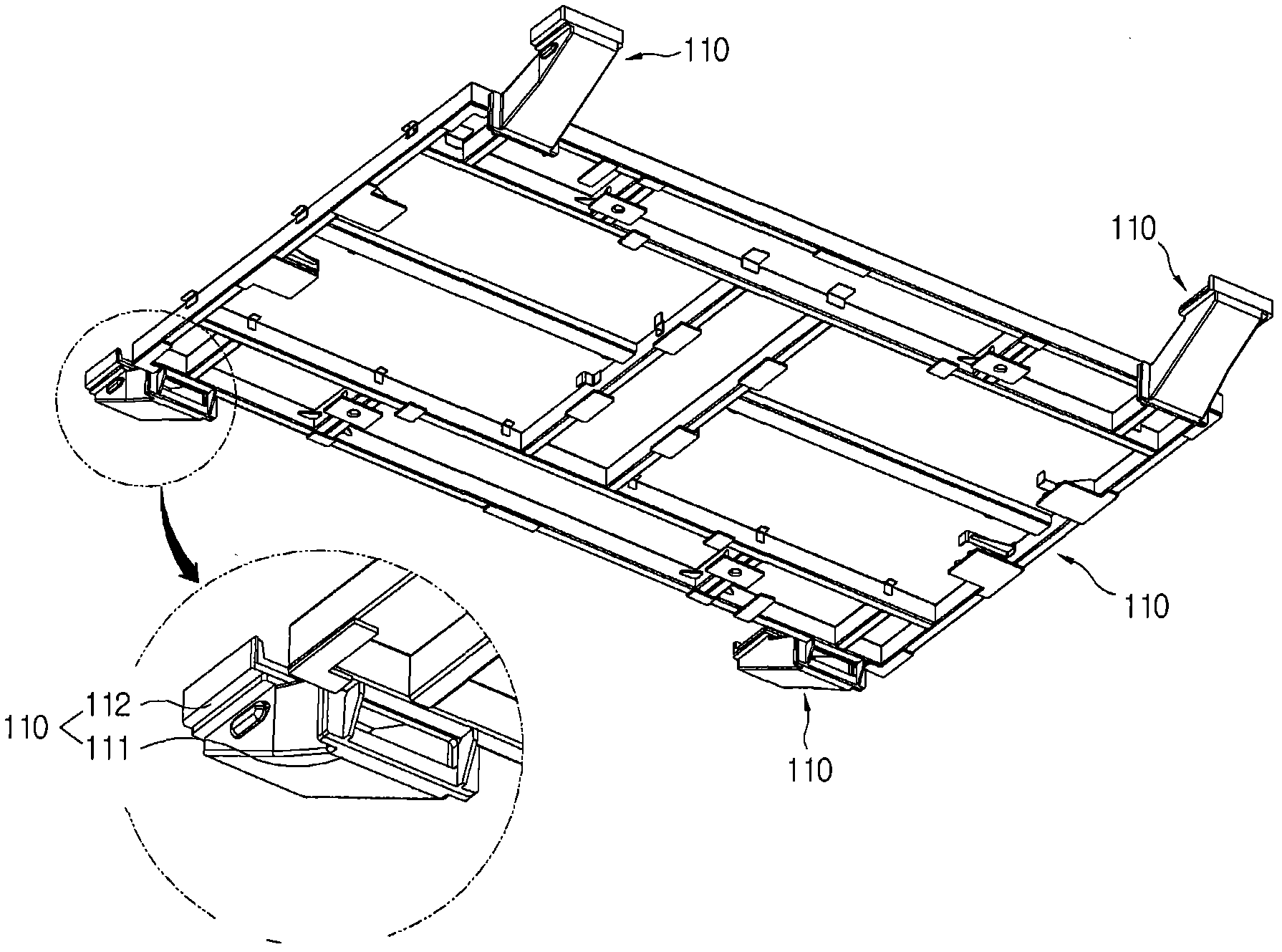

[0061] figure 1 is a perspective view of a magnetic levitation transport system according to an exemplary embodiment of the present invention; figure 2 for figure 1 Partial exploded perspective view of ; image 3 for figure 1 An enlarged view of the shared support frame in ; Figure 4 is an enlarged perspective view of the suspension unit; Figure 5 to Figure 8 for Figure 4 plan, back view, left side view and front view of ; Figure 9 for Figure 4 An enlarged perspective view of a sub-levitation / propulsion unit in the levitation unit shown; Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com