Large submerged arc furnace combined self-baking electrode device capable of removing housing and use method thereof

A self-baking electrode and combined technology, which is applied in the direction of electric heating devices, electrical components, heating by discharge, etc., can solve the problems of integration into submerged arc furnaces, high iron content, and limited cross-sectional size, so as to ensure product quality and reduce iron content, the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

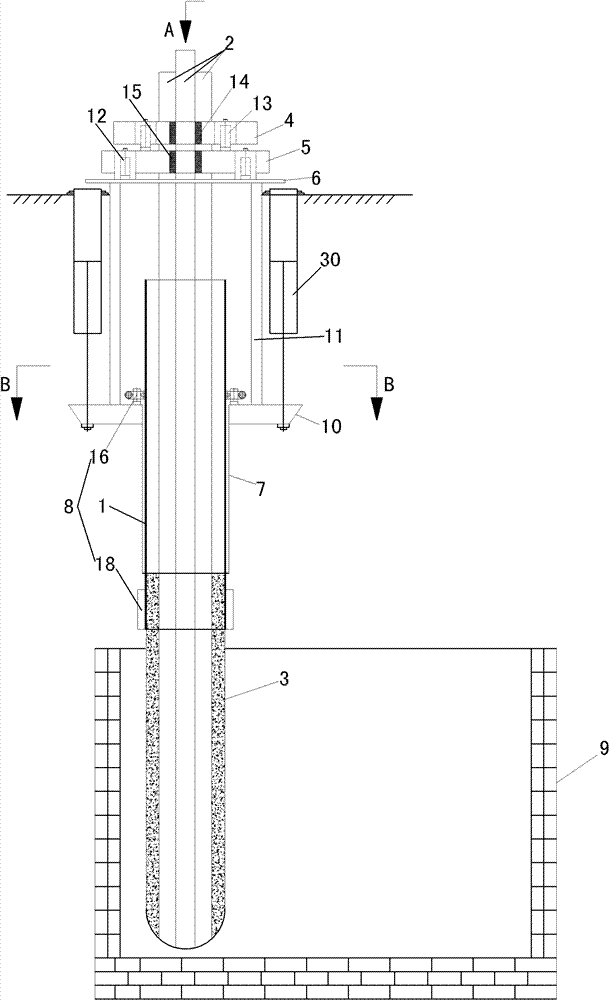

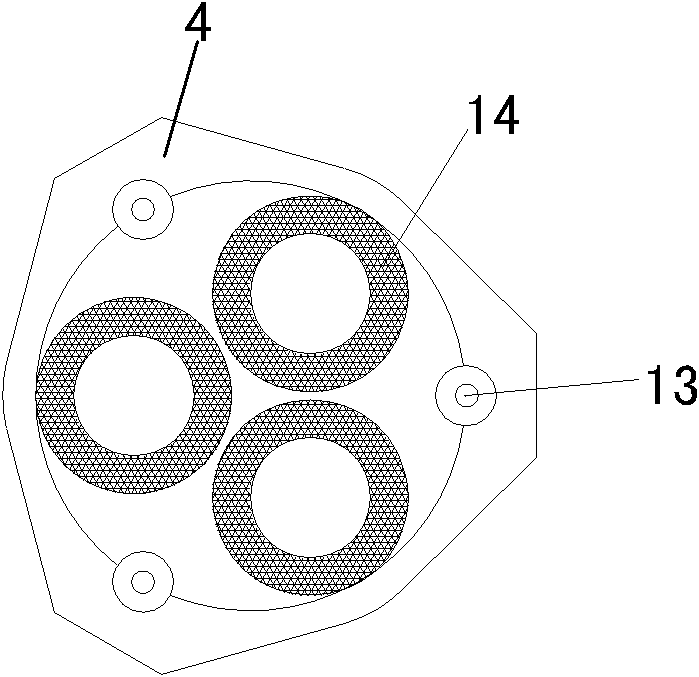

[0026] Such as figure 1 The shown large-scale submerged arc furnace combined shell self-baking electrode device of the present invention includes three carbon electrodes 2, an upper electrode depressing supporting platform 4, a middle electrode depressing supporting platform 5, a lower electrode depressing supporting platform 6, Holding cylinder 7 and combined gripper 8;

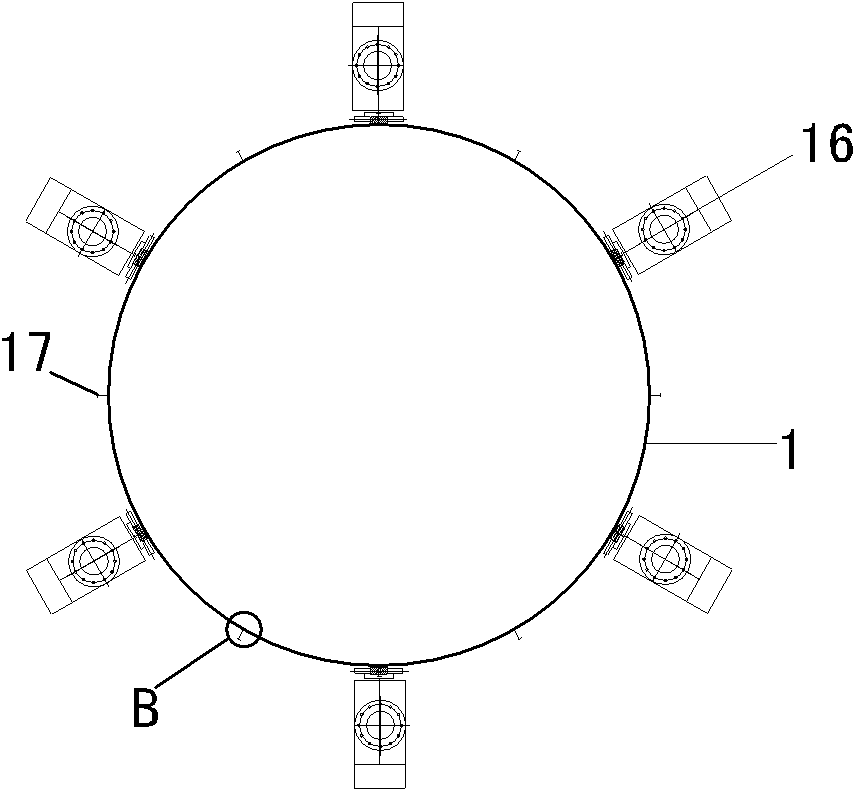

[0027] The combined holder 8 is composed of a cylindrical electrode shell 1, 6 electrode shell clamping and pressing devices 16 and 12 pairs of contact elements 18. The electrode shell 1 is cylindrical, and the electrode shell 1 is made of δ6mm-δ10mm thick conductive heat-resistant performance. Good ferritic stainless steel material, this kind of material has a small thermal expansion coefficient, the present invention abandons most of the existing electrode shells and uses ordinary carbon steel, the electrode shell 1 in the present invention has strong oxidation resistance and high temperature resistance, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com