Fiber optic furcation assembly

A bifurcation and optical fiber technology, applied in optical components, light guides, optics, etc., can solve problems such as micro-bending of optical fibers, transmission loss, and damage to optical fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

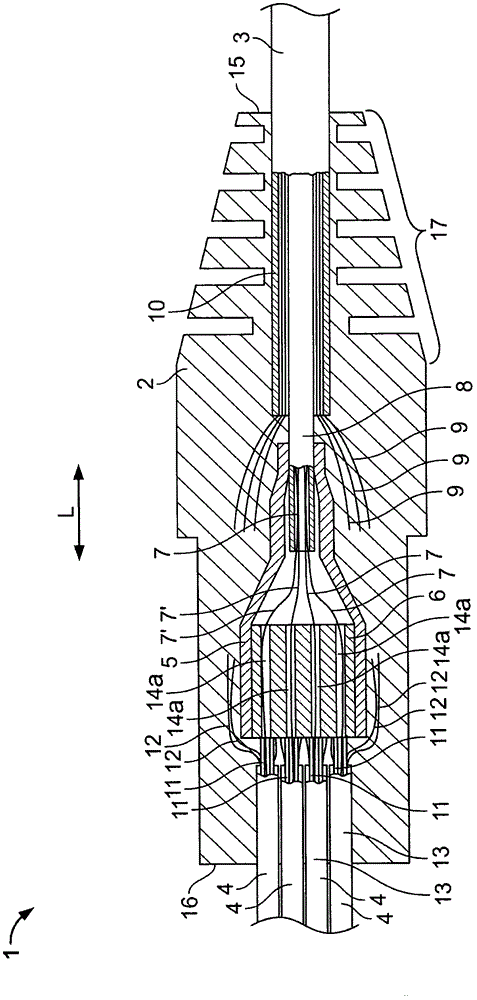

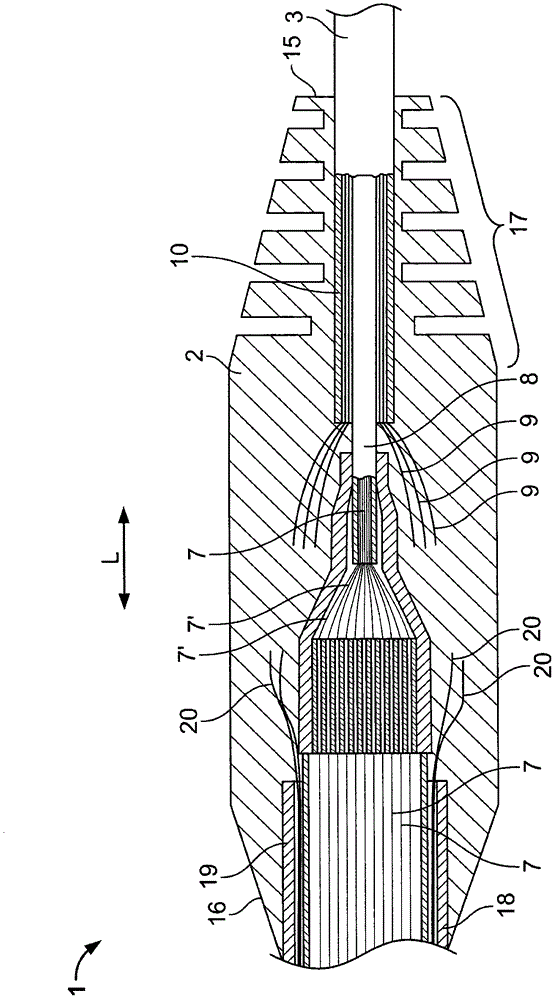

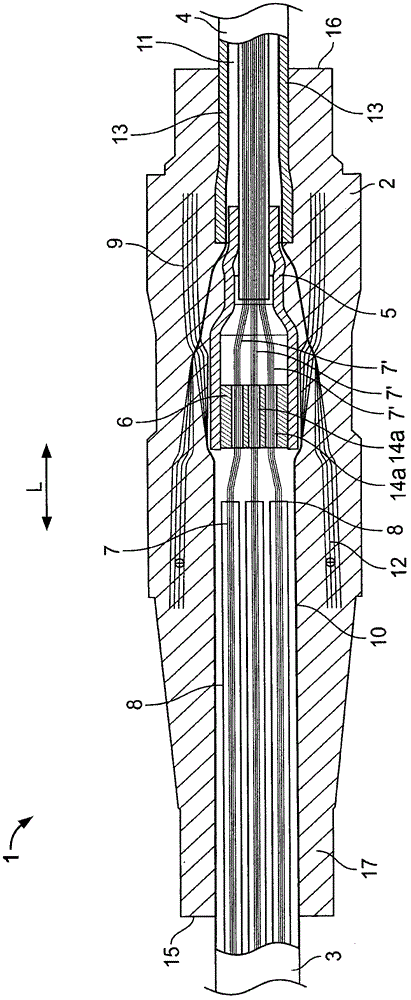

[0054] will now refer to figure 1 Preferred embodiments of the present invention are described.

[0055] The furcation assembly 1 comprises an overmolded body 2 enclosing a distribution fiber optic cable 3 and a furcation fiber optic cable 4 formed as a plurality of loose tube individual fiber optic cables 4 . The furcation assembly 1 also includes a protection tube 5 and a fiber guiding element 6 .

[0056] The fiber optic cable 3 extends into the overmolded body 2 along the longitudinal direction L. As shown in FIG. The optical cable 3 includes a plurality of optical fibers 7 . The optical fiber 7 is surrounded by a buffer tube 8 . Advantageously, the cable 3 has a set of strength members 9, preferably made of aramid. The housing 10 covers the fiber optic cable and protects the fiber optic cable from environmental pollution.

[0057] A single fiber optic cable 4 also extends into the overmolded body 2 in the longitudinal direction, but opposite the fiber optic cable 3 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com