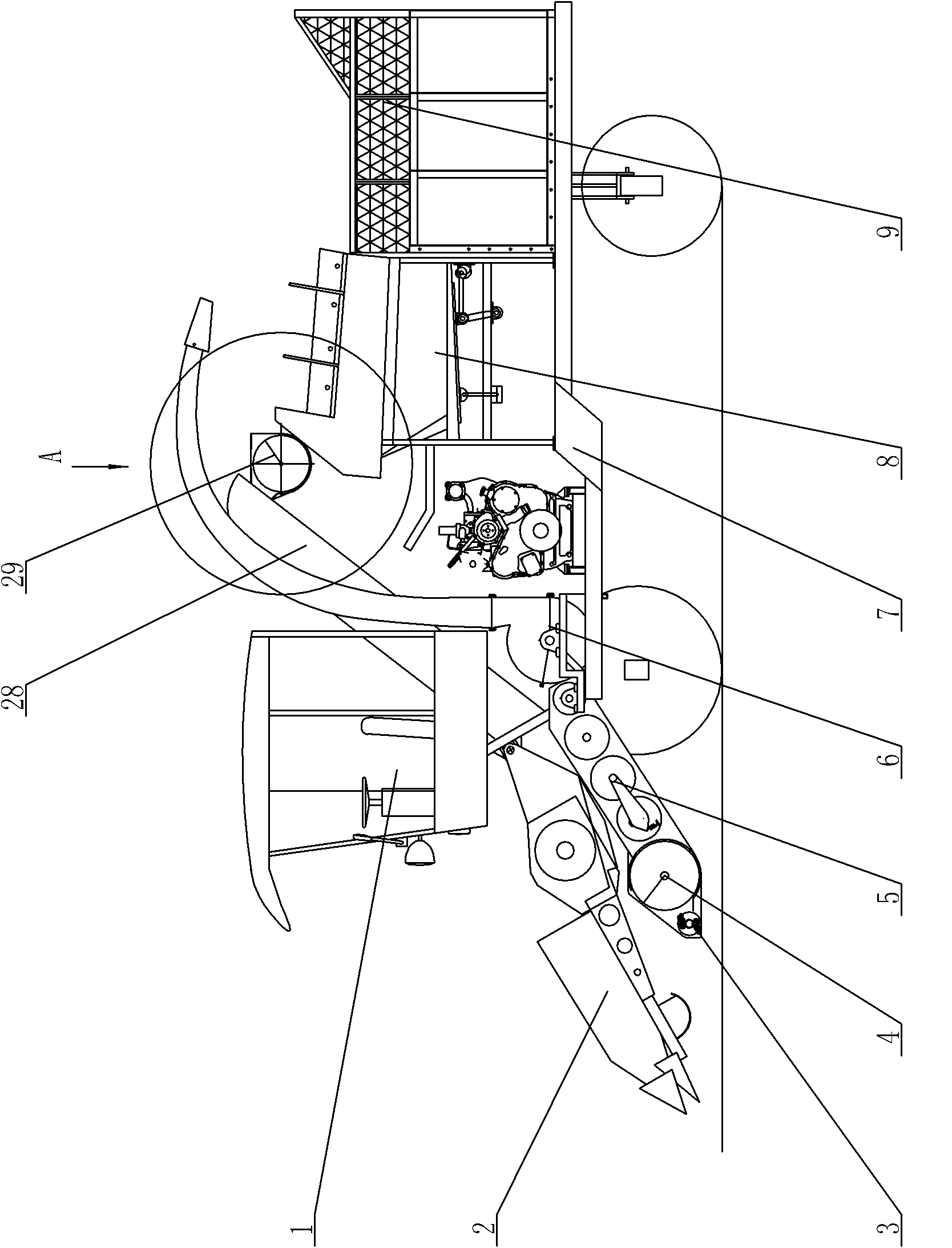

Corncob and cornstalk harvesting type self-propelled corn combine harvester

A combine harvester, self-propelled technology, applied in the direction of harvesters, loaders, crop processors, etc., can solve the problem of no corn stalk recycling function, to improve social and economic benefits, simple structure, less power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

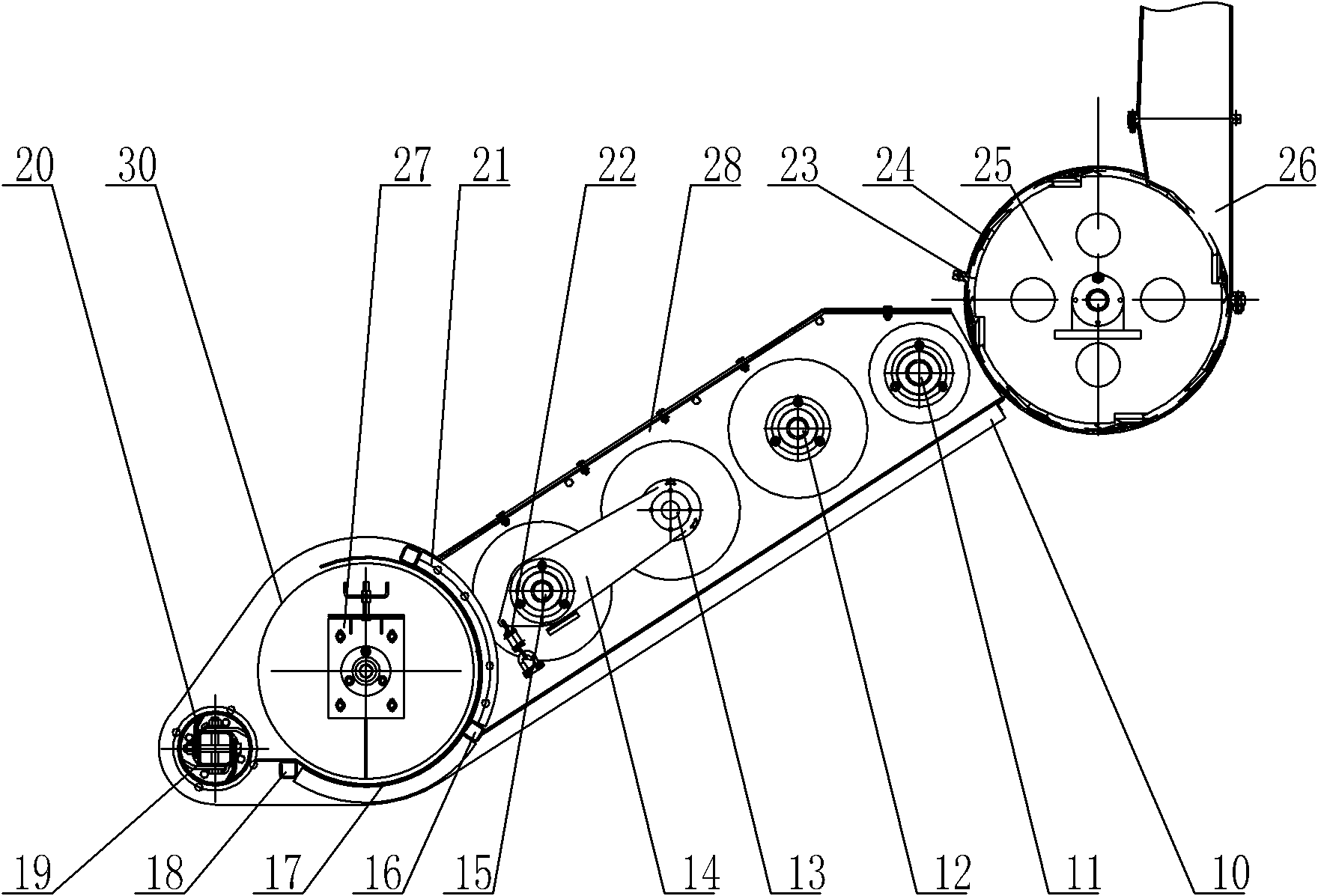

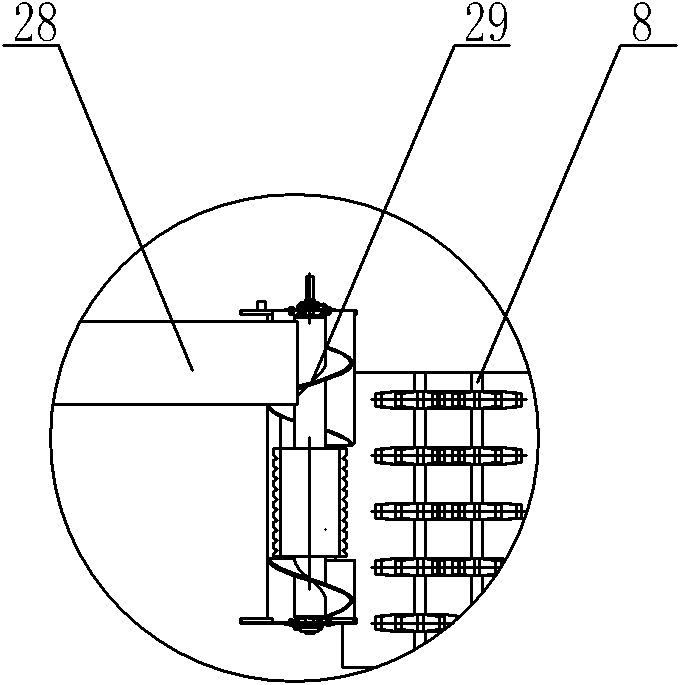

[0026] Such as Figure 1-Figure 7 As shown: the cab 1 is installed on the frame 7, the ear elevator 28 is installed on the right side of the cab 1, the plate type ear picking device 2 is installed at the front and bottom of the cab, and the straw picking device 2 is installed below the plate type ear picking device 2. The cutting device 3 and the straw collecting device 4, the straw conveying device 5 and the straw cutting and throwing device 6 installed under the driver's cab 1, the peeling device 8 installed on the frame 7, and the upper end of the plate-type ear picking device 2 pass through the upper cutting platform The rotating shaft is connected to the cab 1, and the lower end is connected to the bridge 10 through the suspension plate. When working, the hydraulic cylinder is against the suspension plate, and the suspension plate acts on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com