Automation garlic bolt reaper

A technology for harvesters and garlic sprouts, which is applied to harvesters, picking machines, agricultural machinery and implements, etc., can solve the problems of low efficiency, time-consuming and labor-intensive garlic sprouts, etc., and achieve the effect of convenient operation and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

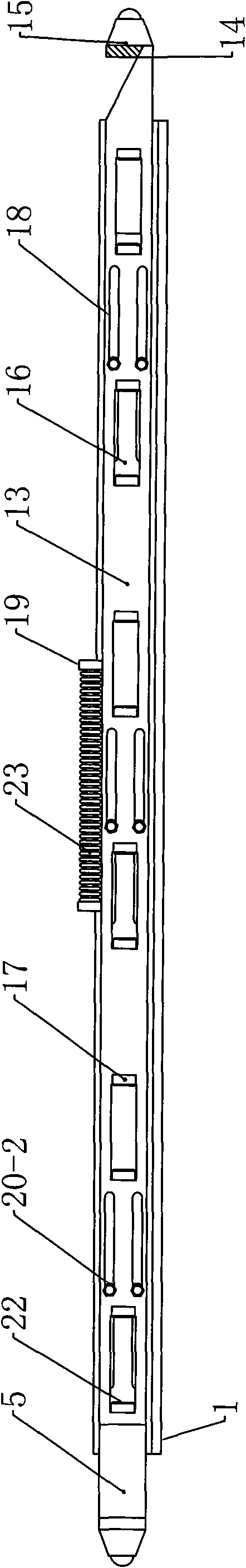

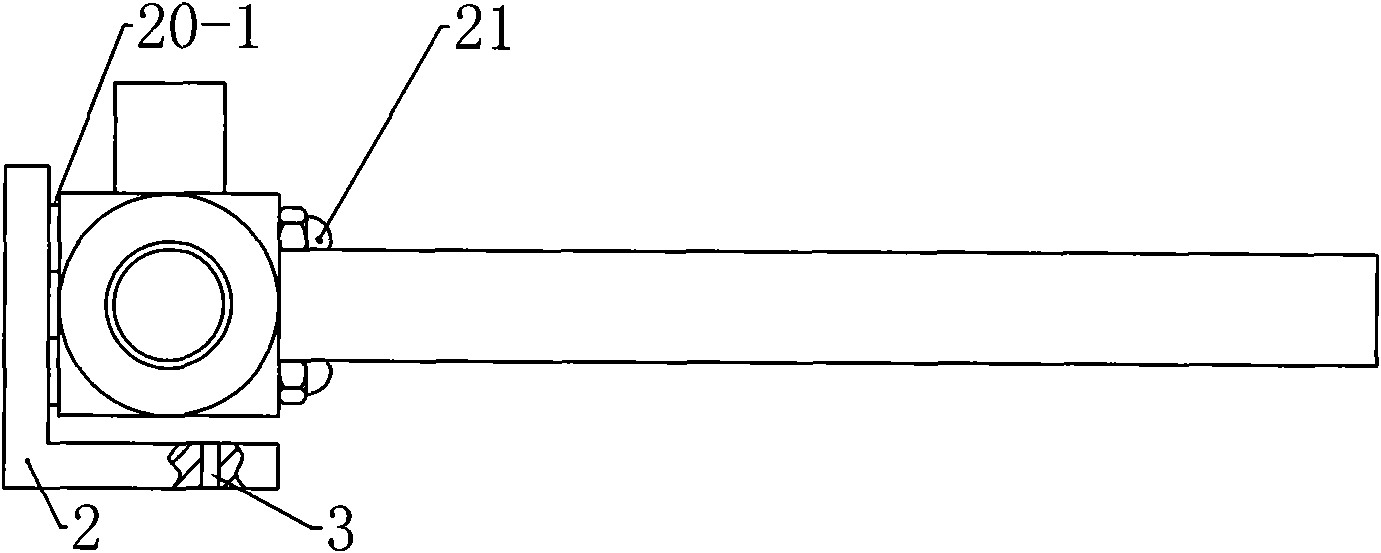

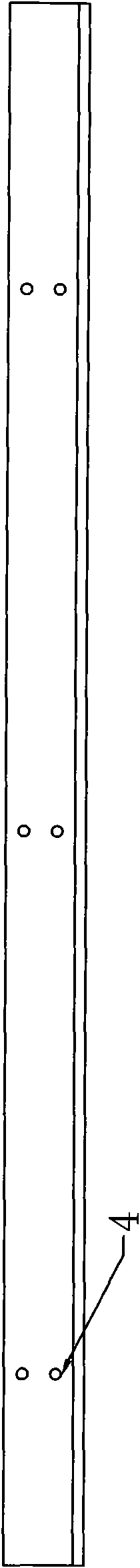

[0018] For examples of bolting components, see figure 1 , figure 2 , image 3 and Figure 4 , the basic part of the base 1 is angle steel 2, the two ends of the angle steel 2 are on the same angle steel plate is the screw hole 3 for the installation of the chain bending plate, and the center position of the inner plate surface of the other angle steel plate is two rows and three columns, and the column width is 400mm 1. Six round sticks 4 with threaded ends protruding in a certain line-space array. The base part of the rear clip 5 is a narrow steel plate 6, one end of which is a forward flange plate 7; the outer surface of the flange plate 7 has an inherent universal ball 8; 1. The clips 9 with a column width of 200 mm and an array of lordotic projections, these six clips are biased towards the end of the narrow steel plate 6 without the flange plate 7; counting from the end of the narrow steel plate 6 with the flange plate 7, the first, third, fifth The same side of each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com