Technology for manufacturing soles of shoes dedicated for drivers

A driver and shoe-making technology, applied in soles, footwear, applications, etc., can solve problems such as not being able to meet the needs of drivers' special shoes, and achieve the effect of uniform force and safe braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

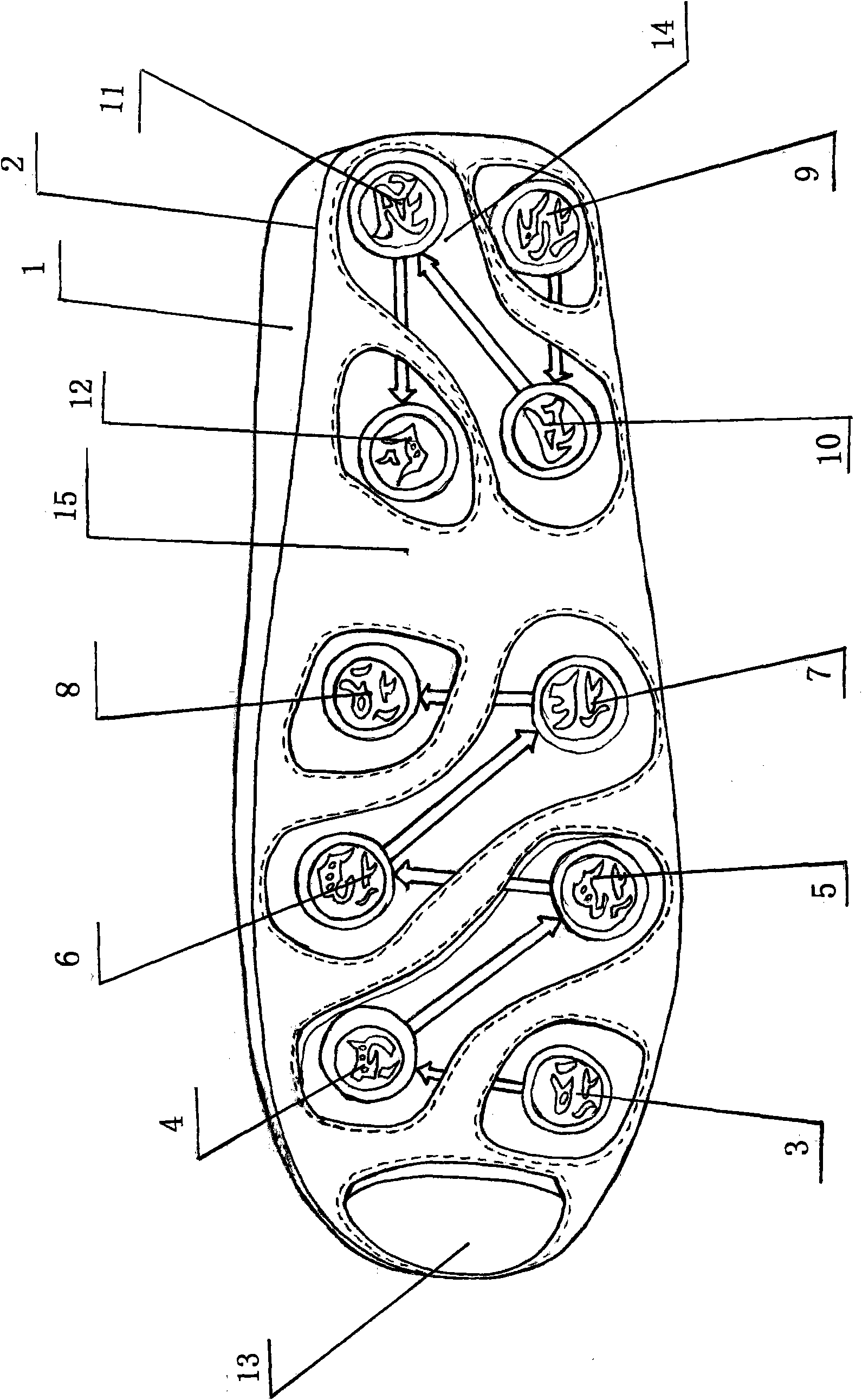

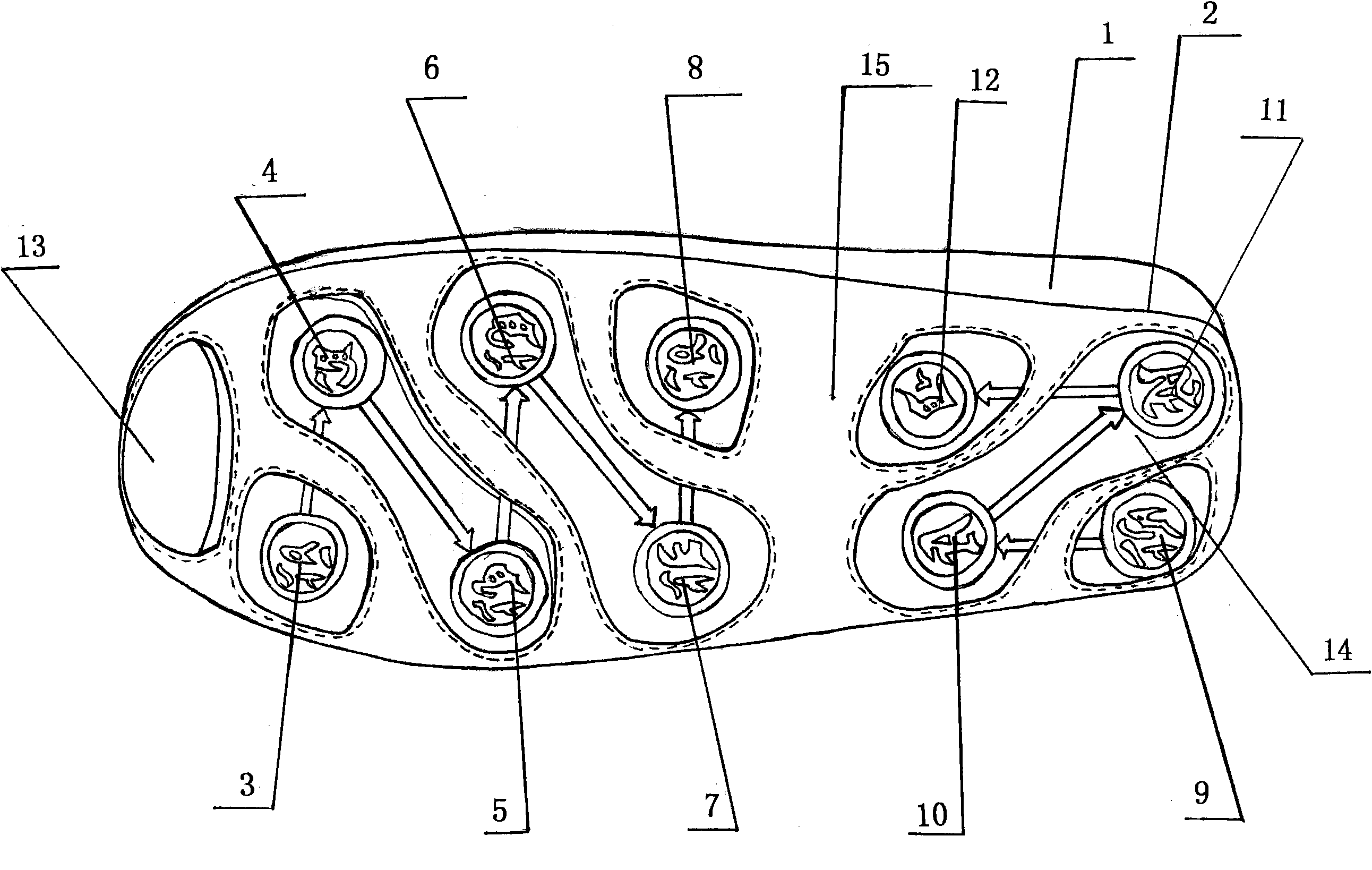

[0008] Embodiment 1: As shown in the figure, a sole-making technology for drivers’ special shoes. The special feature is that while the midsole is eliminated, the upper surface 1 and the sole 2 of the shoe are integrated. position and the landing point when walking, the positions of anti-slip bottom sheets 3, 4, 5, 6, 7, 8, 9, 10, 11, and 12 have been developed, and the "block" design structure is adopted, embedded in the sole 2, directly passing through The insole is in contact with the human feet, so that the driver is evenly stressed when stepping on the brakes, relieves fatigue, improves the sensitivity of the human feet in contact with the accelerator and brakes, and improves driving safety; 13. The heel portion 14 is 8mm higher than the outsole 15, and has a good anti-skid function.

Embodiment approach 2

[0009] Embodiment 2: As shown in the figure, a special shoe-making technology for drivers. Its special feature is that while the midsole is eliminated, the upper surface 1 and the sole 2 of the shoe are integrated. position and the landing point when walking, the positions of anti-slip bottom sheets 3, 4, 5, 6, 7, 8, 9, 10, 11, and 12 have been developed, and the "block" design structure is adopted, embedded in the sole 2, directly passing through The insole is in contact with the human feet, so that the driver is evenly stressed when stepping on the brakes, relieves fatigue, improves the sensitivity of the human feet in contact with the accelerator and brakes, and improves driving safety; 13. The heel portion 14 is 8mm higher than the outsole 15, and has a good anti-skid function.

Embodiment approach 3

[0010] Embodiment 3: As shown in the figure, a special shoe-making technology for drivers. Its special feature is that while the midsole is eliminated, the upper surface 1 and the sole 2 of the shoe are integrated. position and the landing point when walking, the positions of anti-slip bottom sheets 3, 4, 5, 6, 7, 8, 9, 10, 11, and 12 have been developed, and the "block" design structure is adopted, embedded in the sole 2, directly passing through The insole is in contact with the human feet, so that the driver is evenly stressed when stepping on the brakes, relieves fatigue, improves the sensitivity of the human feet in contact with the accelerator and brakes, and improves driving safety; 13. The heel portion 14 is 8mm higher than the outsole 15, and has a good anti-skid function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com