Magnetic shoe sorting device and sorting method thereof

A magnetic tile, sorting technology, applied in chemical instruments and methods, grading, solid separation and other directions, can solve the problems of waste of manpower and material resources, scrapping, product collapse, etc., to improve efficiency, ensure continuity, and facilitate disassembly and assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the content of the present invention more obvious and understandable, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

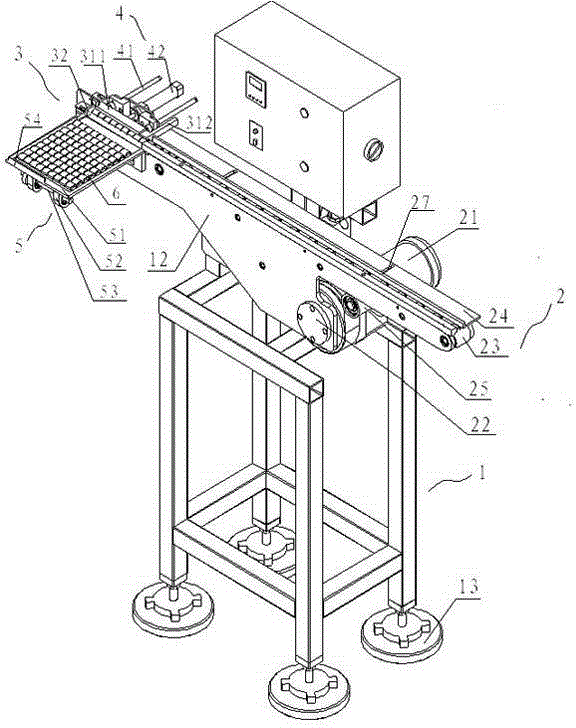

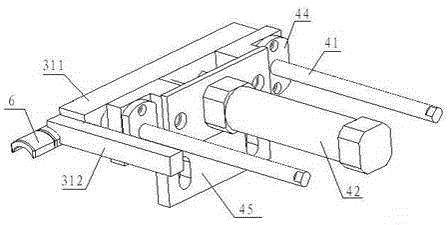

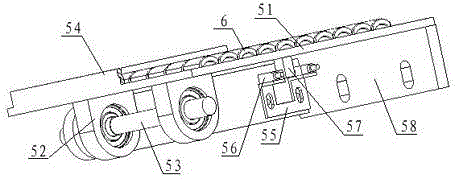

[0035] combine Figure 1 to Figure 4 Shown is a schematic diagram of a specific embodiment of the present invention. The magnetic tile sorting device includes a bracket 1, a main support plate 12, a conveying mechanism 2, and a magnetic tile sorting and processing mechanism. The magnetic tile sorting and processing mechanism includes a pneumatic mechanism 4 and a tile pushing mechanism. 3. Turnover mechanism 5, wherein: the main support plate 12 is vertically fixed on the support 1; the conveying mechanism includes a conveyor belt 25, a motor 21, a driving wheel 22, and a driven wheel 23; the driving wheel 22 is axially parallel to the driven wheel 23, All are installed on the main support plate 12, and the axial direction of the driving wheel 22 and the driven w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com