Modeling method for dual-driving synchronous electromechanical coupling characteristic of walking beam type gantry machine tool

A technology of gantry machine tool and modeling method, which is applied in the direction of metal processing, etc., can solve the problems of not considering the difference of friction between two axes, not reflecting the working principle of the control system, and not establishing the control model part of the mechanical coupling of two axes, etc. To achieve the effect of easy realization and reduction of synchronization error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The implementation method of the present invention will be further described in detail below in conjunction with the accompanying drawings and a complete dual-drive synchronous control model built.

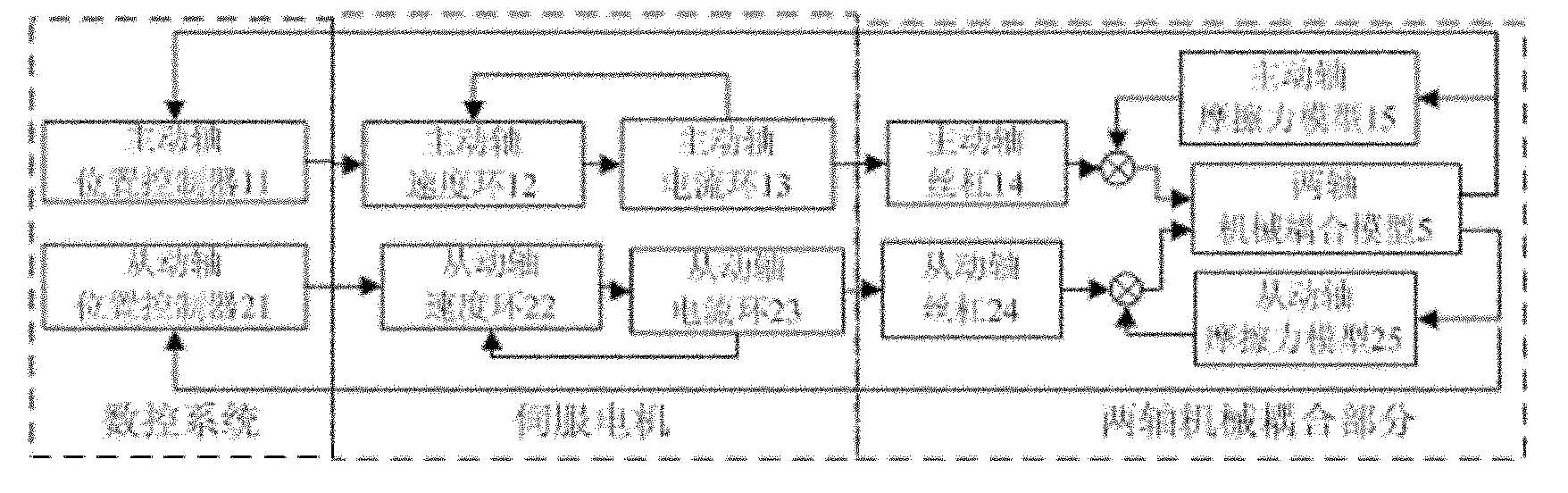

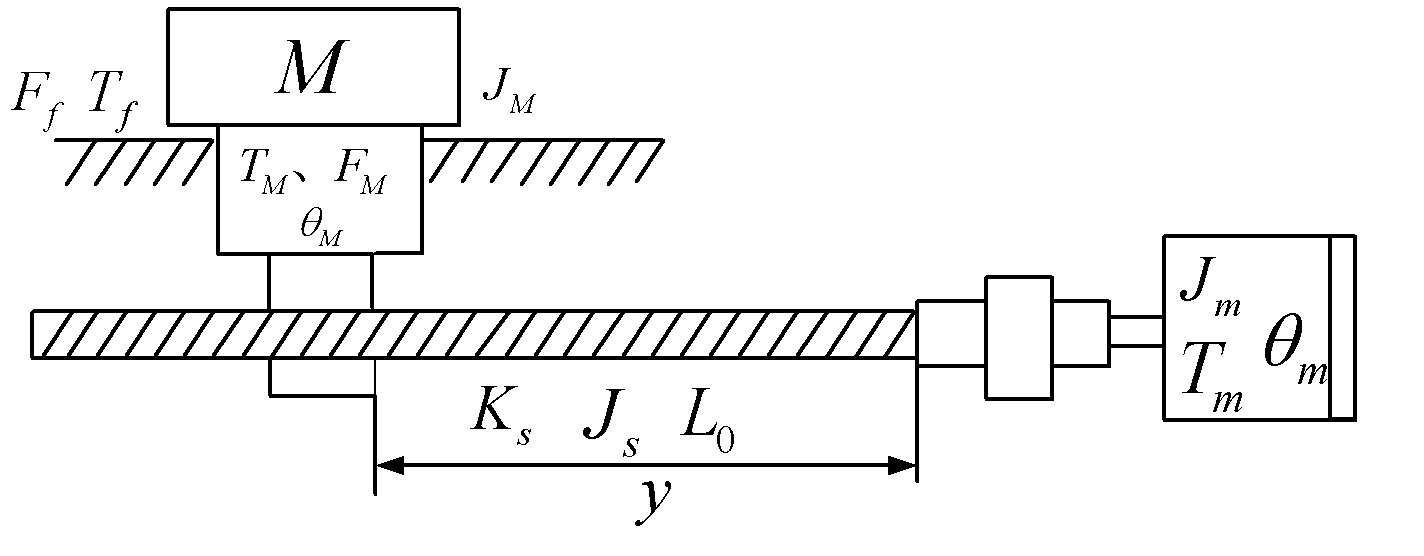

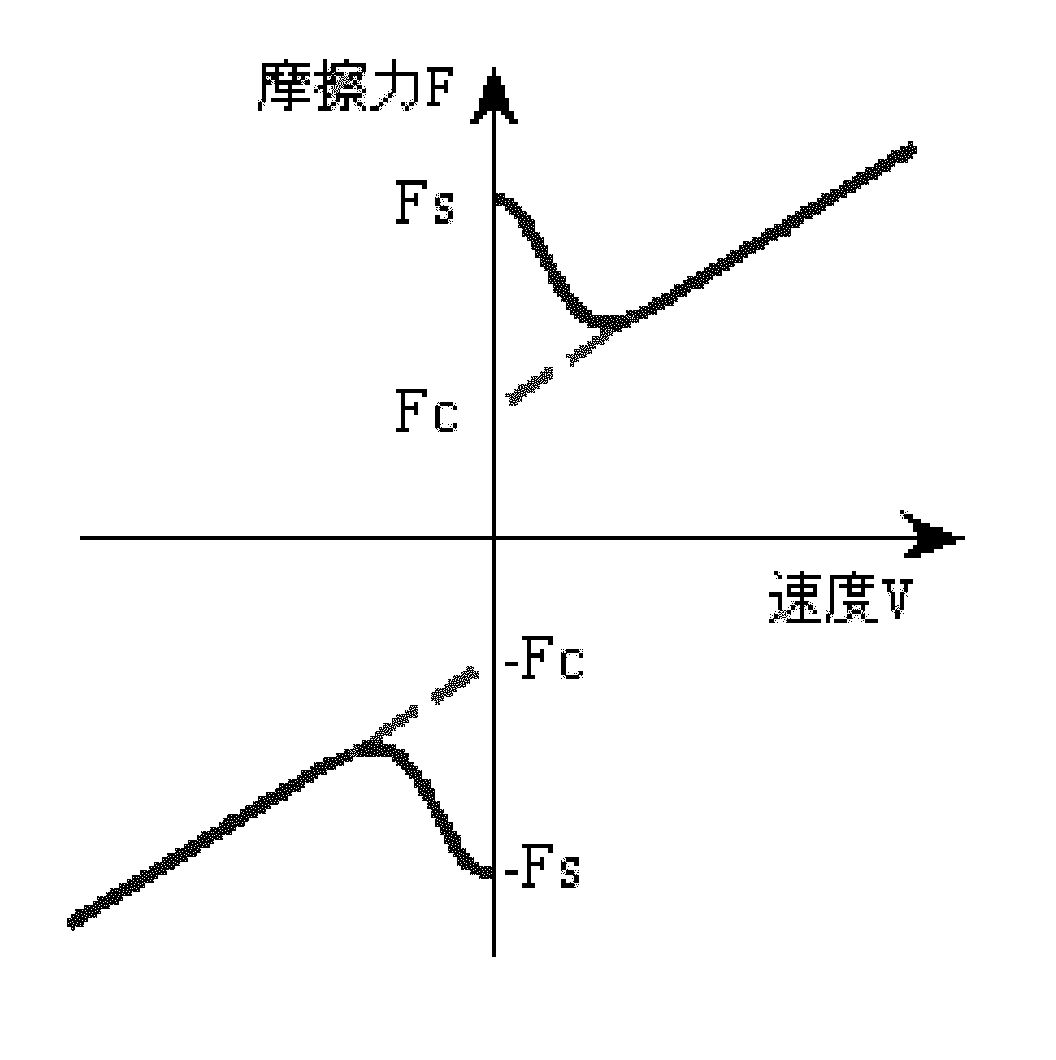

[0040] In the present invention, since the dual motors jointly drive the coupling part to perform unidirectional feed movement, the composition of each part of the transmission system is not much different from that of the single-axis feed system. The mechanical coupling between the moving parts and the two axes, so the analysis and modeling method of the single-axis feed system can be used to establish the two-axis control model. Firstly, the single-axis feed system transmission model is established, and then the mechanical coupling part of the dual-drive and two-axis is considered, and then the dual-drive control model is established. Another important part of building a model is the establishment of various parameters in the model. In the specific example, a three-axis g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com