Multilayer cloth multi-shed water jet loom

A water jet loom and shed technology, applied in looms, dobby machines, textiles, etc., can solve the problems of single style, high price, restrict the development and utilization of multi-layer fabrics, etc., to increase production efficiency and benefit economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

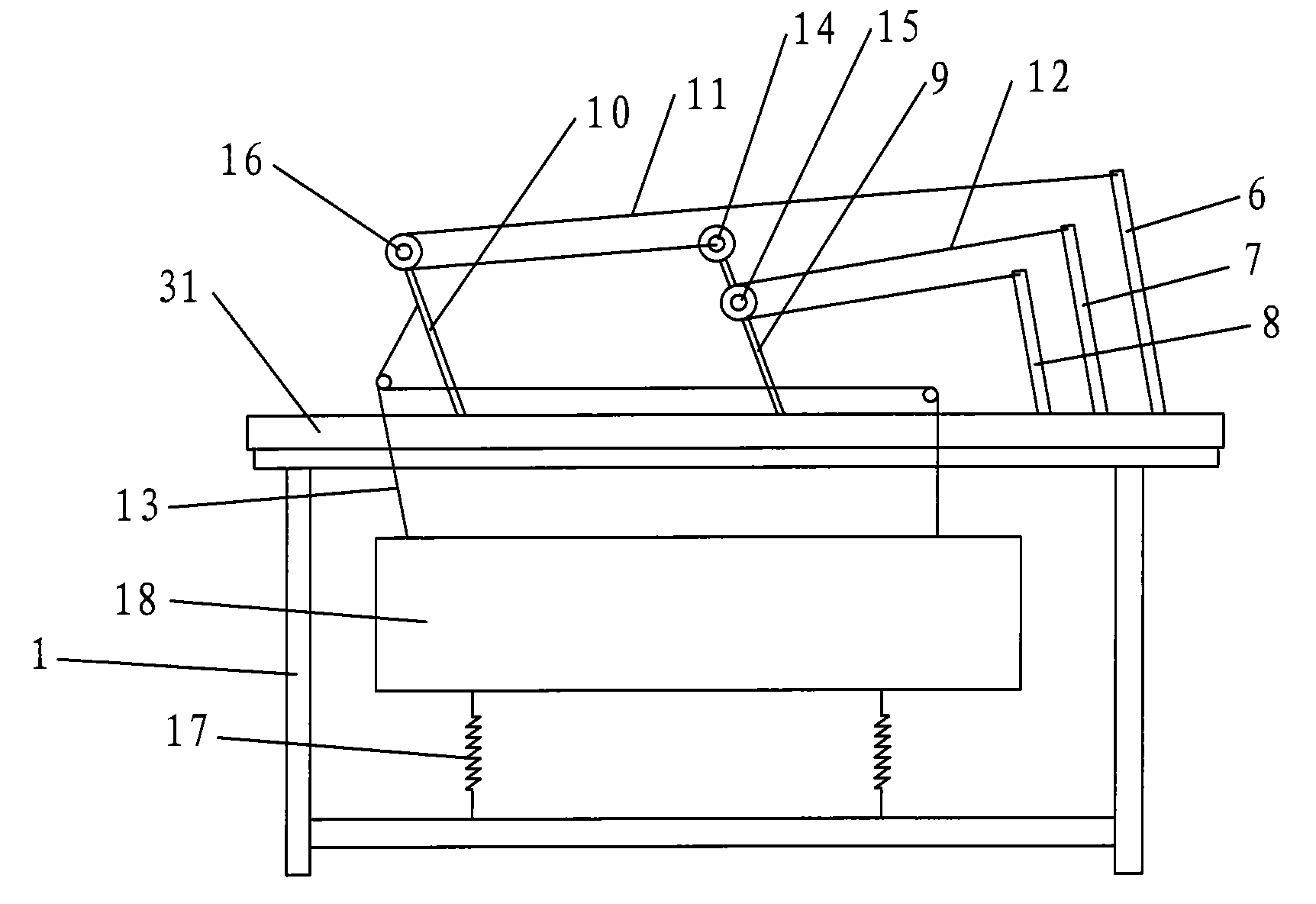

[0023] The present invention will be further described below by means of embodiments in conjunction with the accompanying drawings.

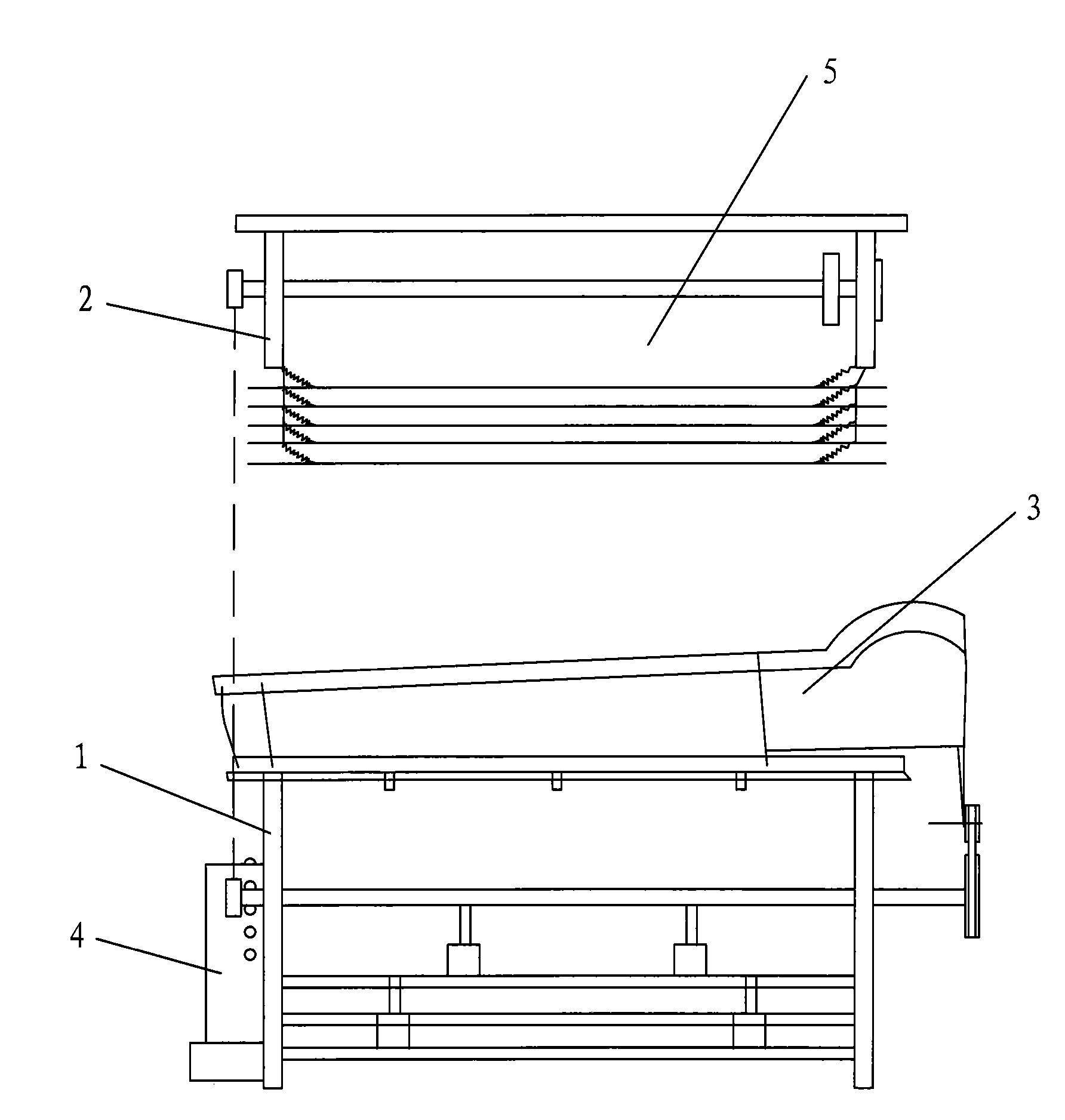

[0024] as attached figure 1 As shown, a multi-layer cloth multi-shed water jet loom comprises a front frame 1 and a rear frame 2, a multi-arm mechanism 3 is installed above the front frame 1, and the front frame 1 A heald frame assembly controlled by the dobby mechanism 3 is provided below, and a weft insertion mechanism 4 is provided on the left side of the front frame 1 .

[0025] Described front frame 1 rear is equipped with ground warp weaving shaft.

[0026] Said warp weaving shaft 55 and tension compensation device 5 are installed on the rear frame 2 .

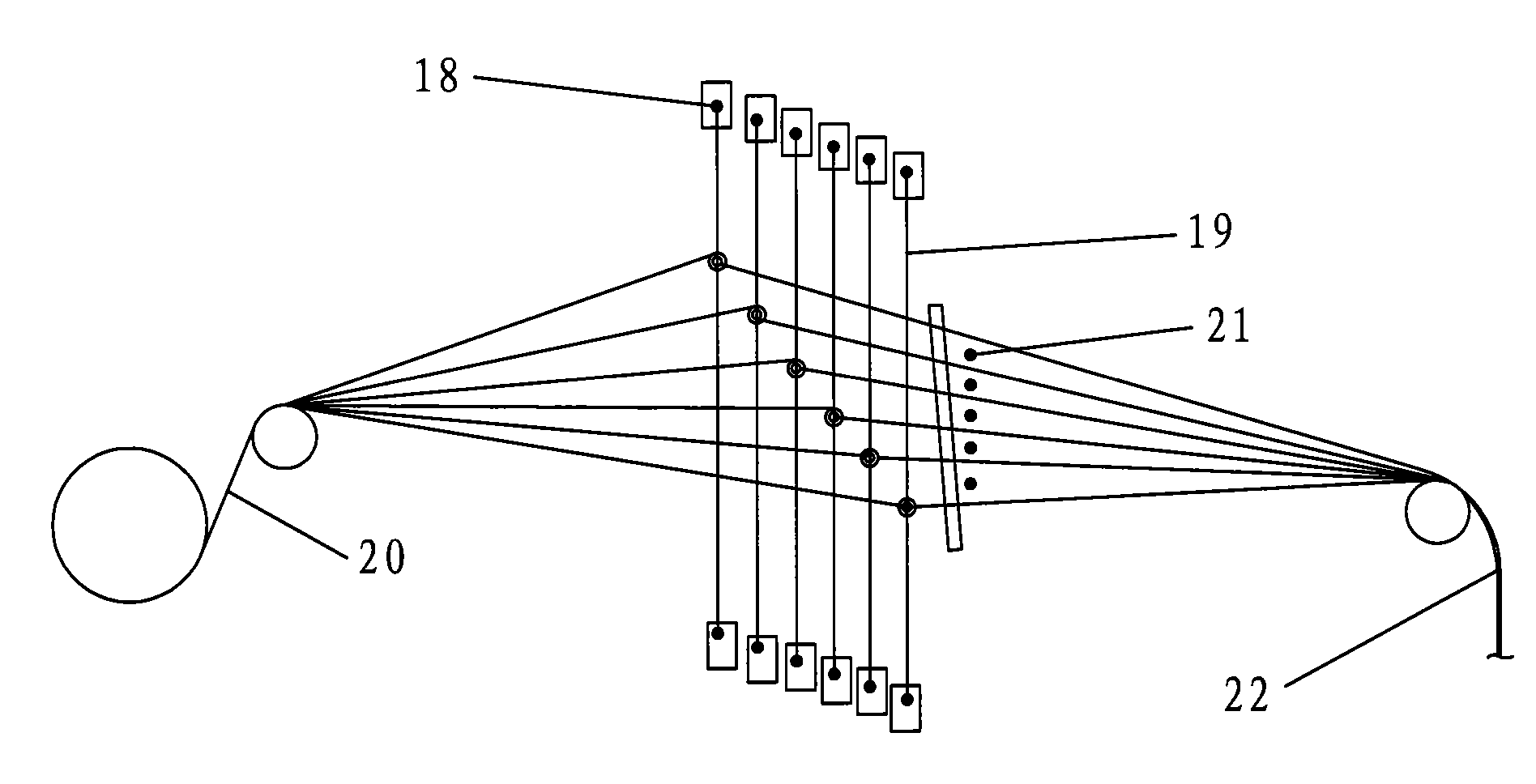

[0027] The described heald frame assembly includes several pieces of seaming through heald frames 18 and several pieces of ground through heald frames, and the described dobby mechanism 3 includes a frame 31 installed above the front frame 1, and several pieces of sewing through heald fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com