Balancing the excess air ratio between the different combustion chambers of an internal combustion engine by running roughness

A technology of excess air coefficient and combustion chamber, applied in electrical control, mechanical equipment, engine control, etc., can solve the problem of reducing the quality of exhaust gas cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

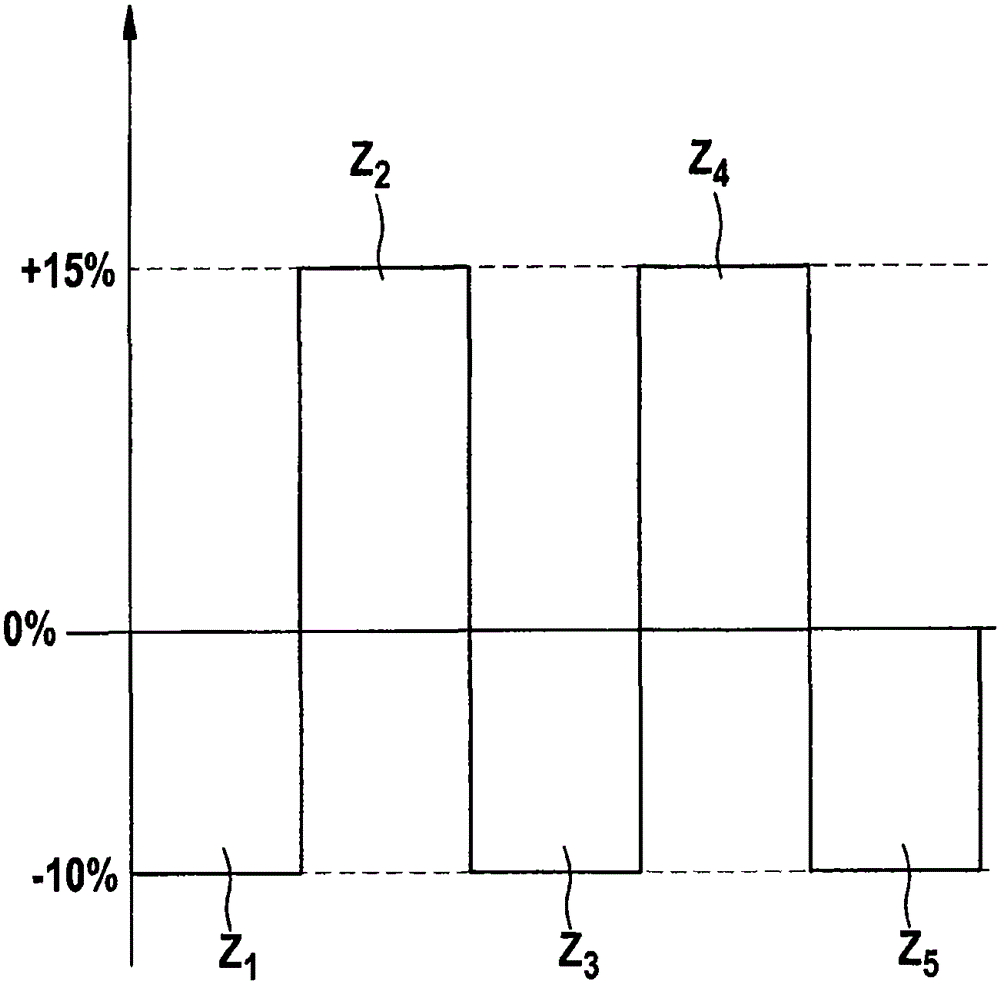

[0031] Reference below figure 2 A first exemplary embodiment of the method aspect of the invention will be described with reference to an application to a five-cylinder internal combustion engine designed as an Otto engine. The method consists of three stages:

[0032] In a first phase, substantially all cylinders of the five-cylinder internal combustion engine are each operated with a first predetermined air-fuel mixture. This first air-fuel mixture has, for example, lambda in equilibrium operation Z =1 excess air ratio, so all cylinders operate with this excess air ratio.

[0033] figure 2 The adjustment (Vertrimmmung) of the excess air ratio in the second phase is shown, in which the individual excess air ratio λ for all cylinders Z1...Z5 In a predetermined manner with the global excess air ratio λ of the internal combustion engine Motor = 1.0 Offset (Amount Adjustment). In this example three cylinders Z 1 ,Z 3 and Z 5 In each case, the operation was performed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com