Upper end sealed fuel valve

A closed, gas-fired technology, applied to valve details, safety valves, balance valves, etc., can solve problems such as increased production processes, increased costs, and difficult installation, to ensure firmness and reliability, facilitate installation, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

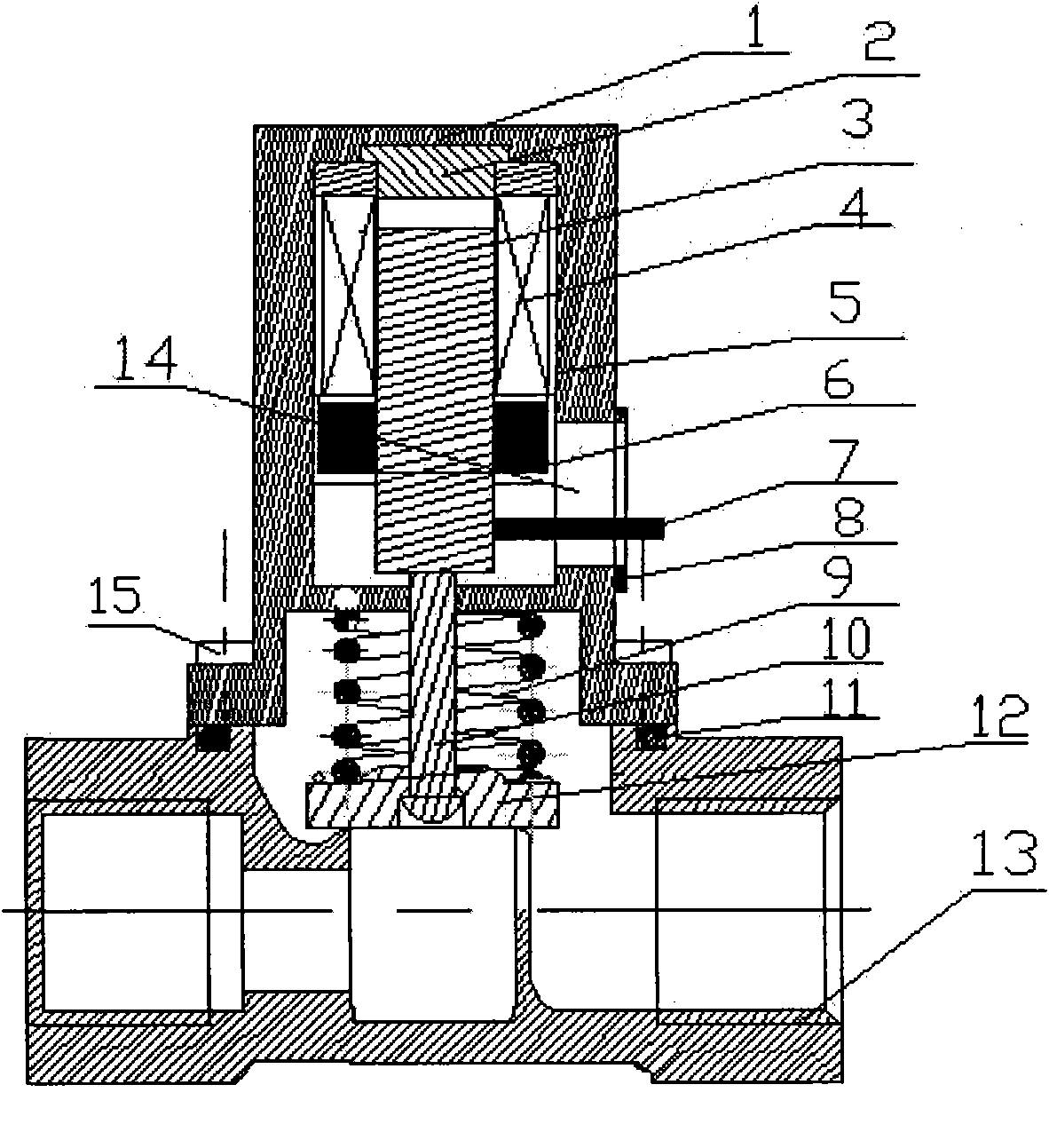

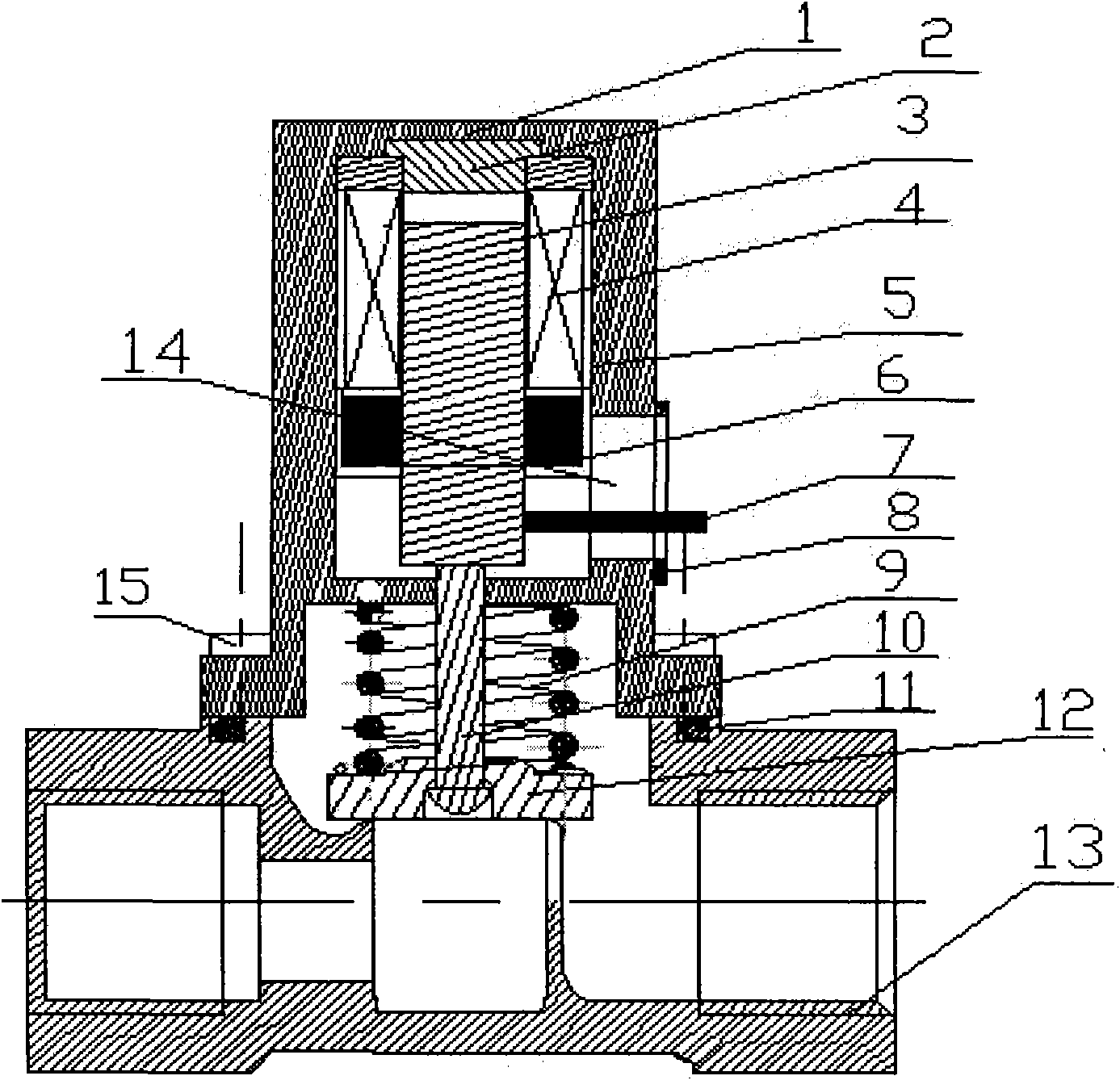

[0014] Below in conjunction with accompanying drawing, the present invention is described in detail.

[0015] Such as figure 1 , an upper-end closed gas valve, comprising an upper casing 1 with a closed top, a lower casing 13 sealingly connected to the upper casing 1 through a screw rod 15 and a sealing ring 11, and a vent hole is arranged in the lower casing 13. Characterized by:

[0016] Between the upper casing 1 and the lower casing 13, a partition made integrally with the upper casing 1 is provided;

[0017] A cavity is formed between the upper casing 1 and the partition, a static iron core 2 is fixed on the top of the cavity, a coil 4 with a magnet 6 is fixed below the static iron core 2, and a moving iron core 3 is installed in the coil 4. A pull rod 7 is fixed on the side wall of the moving iron core 3, and a guide groove 14 is vertically provided on the side wall of the upper casing 1. With sealing cap 8;

[0018] A pull-down rod 10 is fixed at the bottom of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com