Fixed-length cutting control device and method

A control device and control method technology, applied in the direction of digital control, electrical program control, etc., can solve problems such as low production efficiency and large errors, and achieve the effects of improving production efficiency, improving measurement accuracy, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

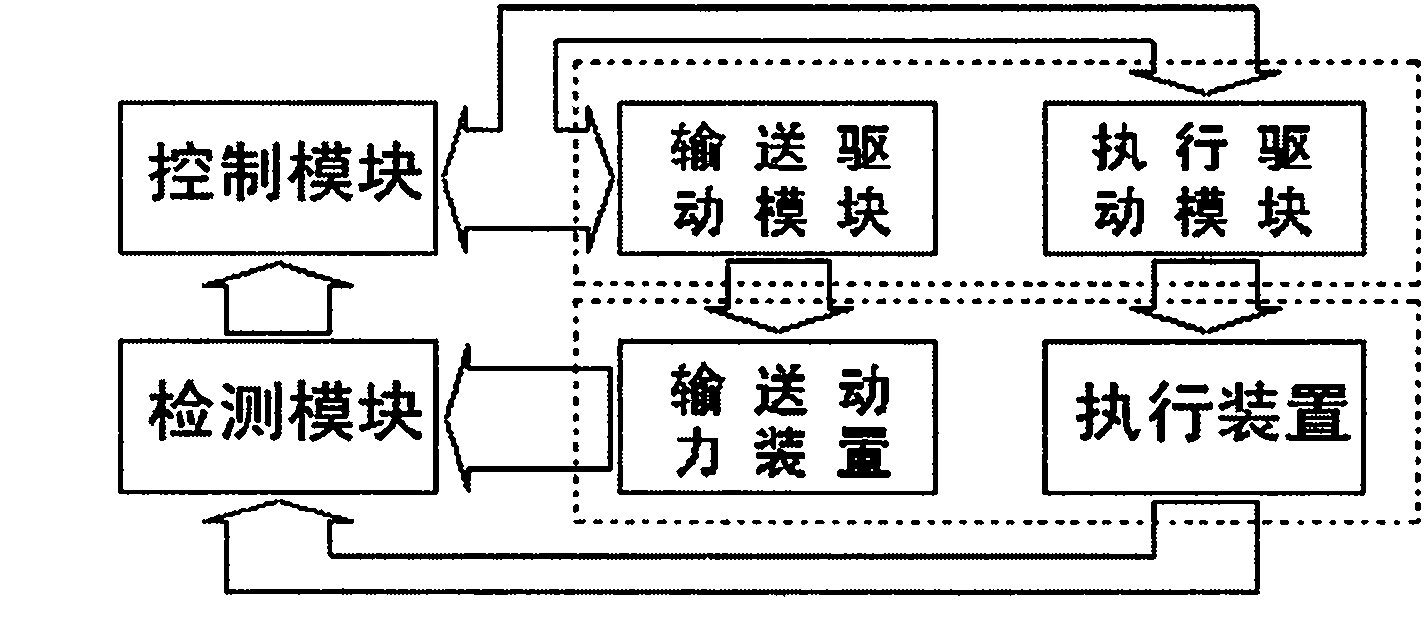

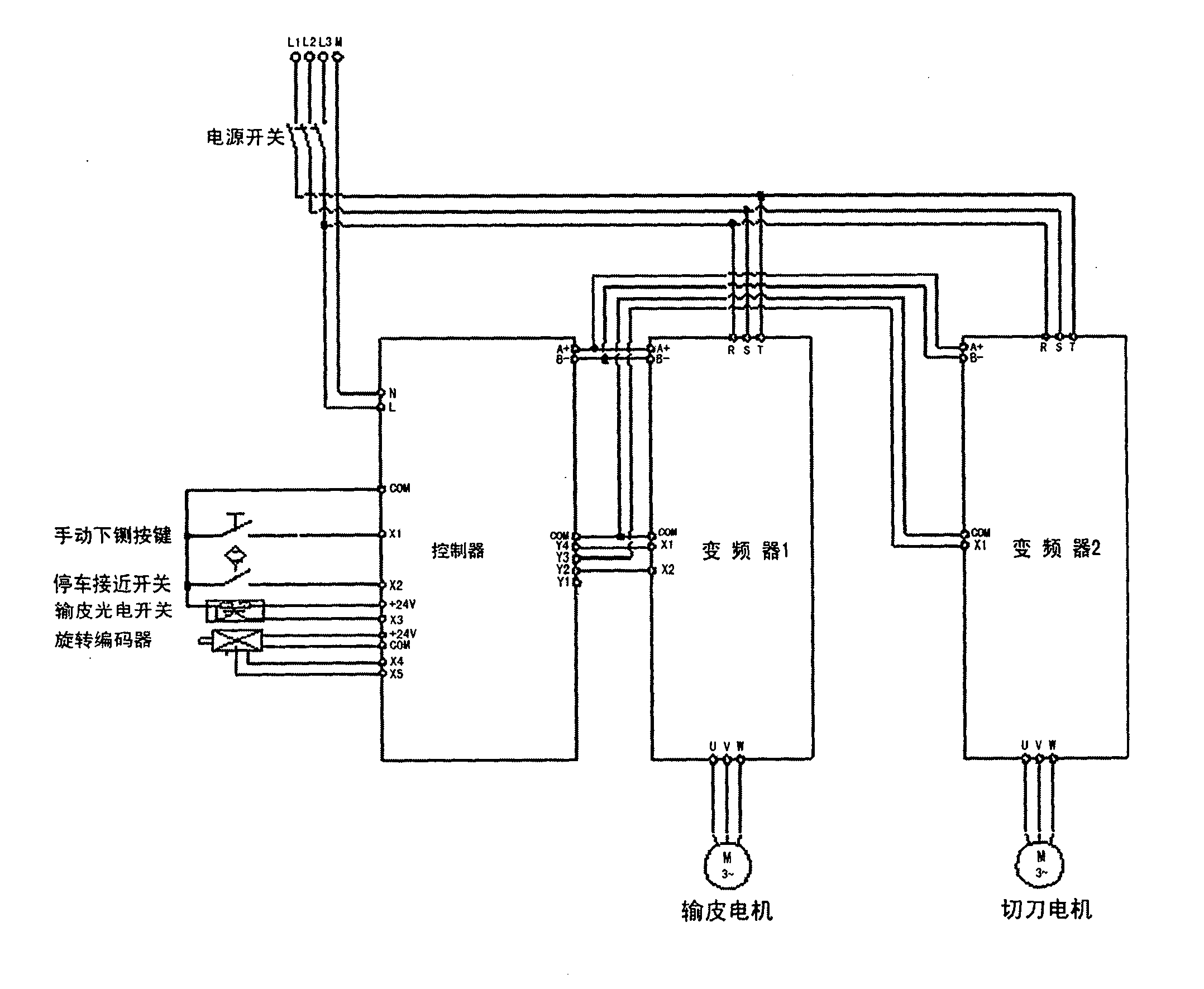

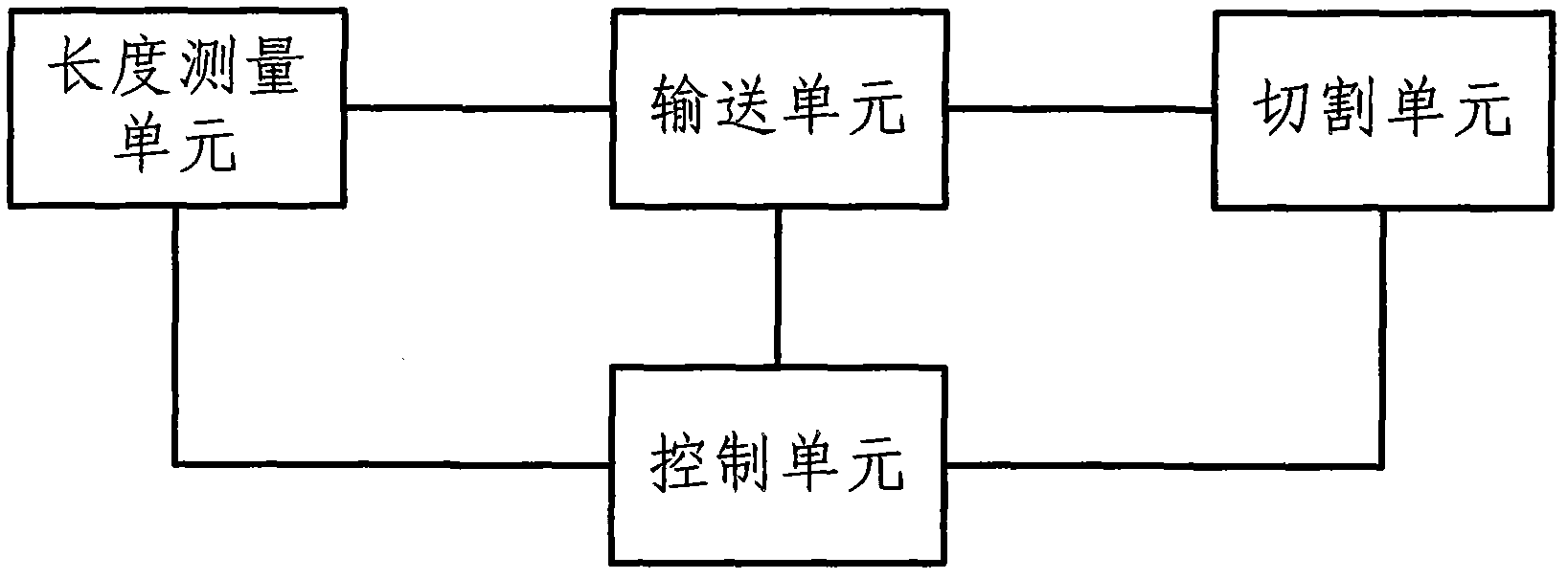

[0027] A cut-to-length control device according to an embodiment of the present invention is as follows: image 3 As shown, it includes power switch, controller, frequency converter 1, skin feeding motor, frequency converter 2, cutter motor, rotary encoder, skin feeding photoelectric switch, knife stop proximity switch and manual down button. Among them, the power switch is respectively connected with the controller, frequency converter 1 and frequency converter 2, and the controller is respectively connected with frequency converter 1, frequency converter 2, rotary encoder, skin-transmitting photoelectric switch, knife stop proximity switch and manual lowering button. The frequency converter 1 is connected with the skin-feeding motor, and the frequency converter 2 is connected with the cutter motor.

[0028] The controller corresponds to the control unit, the frequency converter 1 and the skin feeding motor correspond to the conveying unit, the frequency converter 2 and the c...

Embodiment 2

[0036] when using image 3 In the case of the cut-to-length control device shown, a cut-to-length control method in the embodiment of the present invention is as follows: Figure 4 As shown, the method includes the following steps:

[0037]In step s401, the controller controls the frequency converter 1 and the leather conveying motor to convey the object to be cut according to the input instruction. In this embodiment, after the power switch is closed, the controller, frequency converter 1 and frequency converter 2 start to run, the controller receives the peeling operation command (operated manually through the input panel keys), and the controller communicates with the frequency converter through the Y4 terminal and RS485 respectively. The forward running signal and running frequency of the converter 1, the frequency converter 1 drives the transmission motor to transport the material to be cut.

[0038] Step s402, when the object to be cut reaches the output photoelectric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com