Equipment failure prediction method based on point polling data and DCS (Data Communication System) online data

A technology of equipment failure and prediction method, applied in the direction of electrical testing/monitoring, etc., can solve problems such as the expansion of the failure situation, the maintenance work affecting the normal production, and the failure to find the failure as soon as possible.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

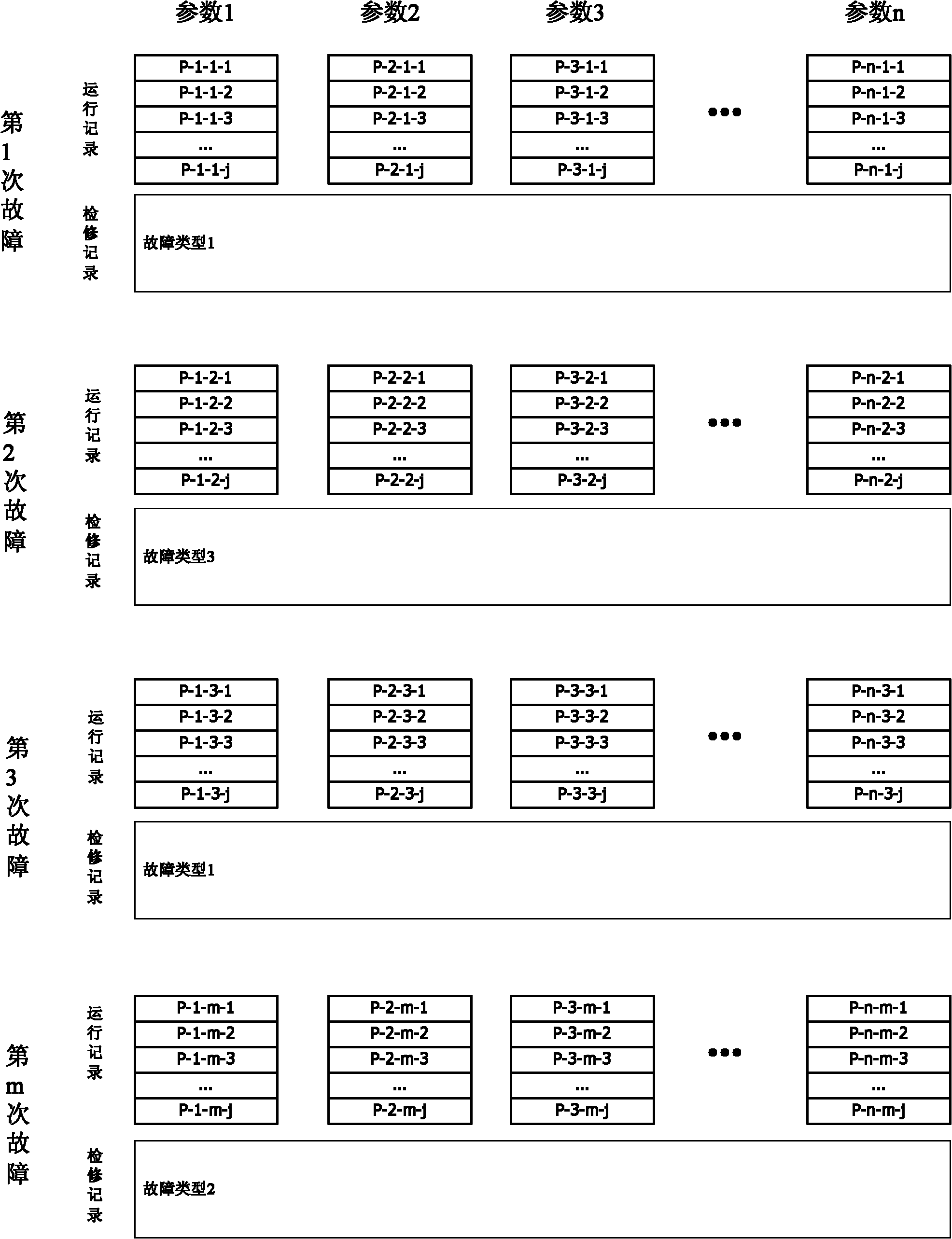

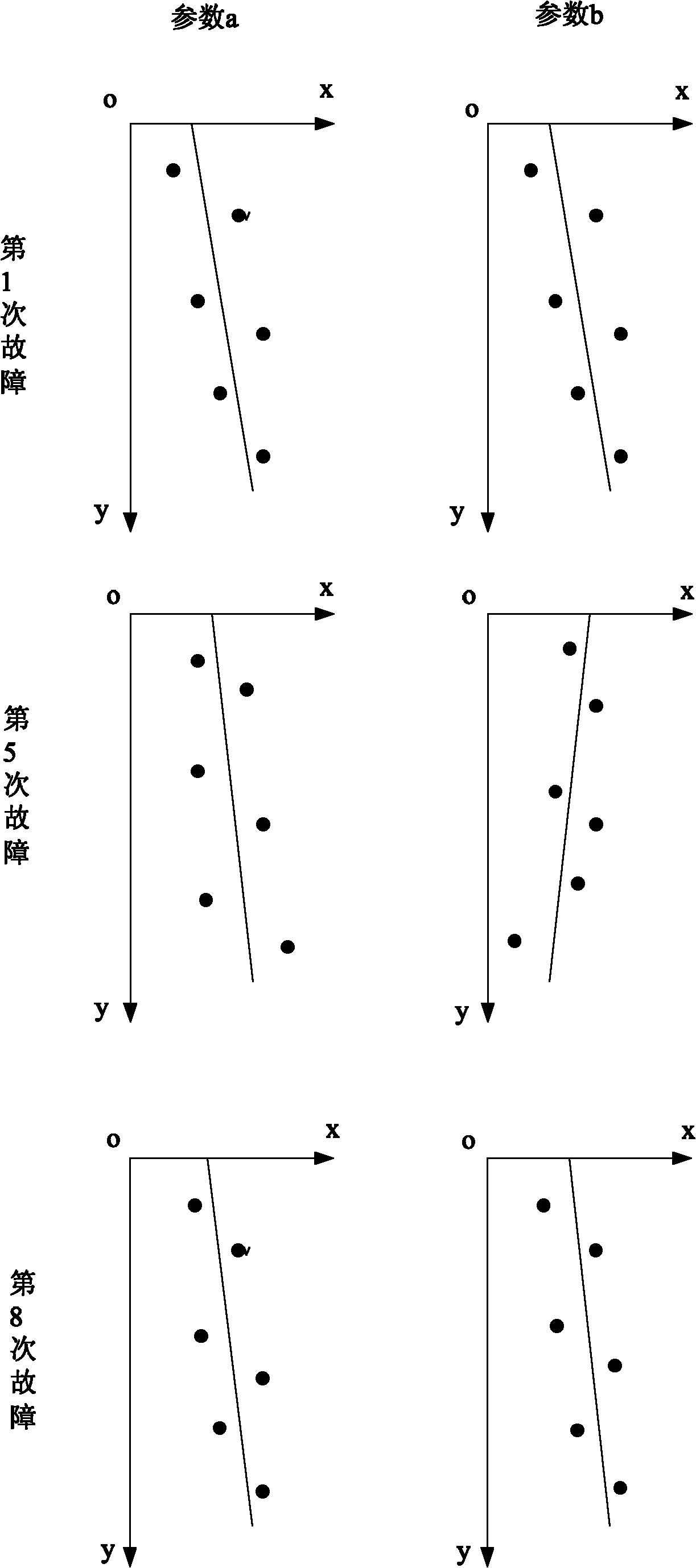

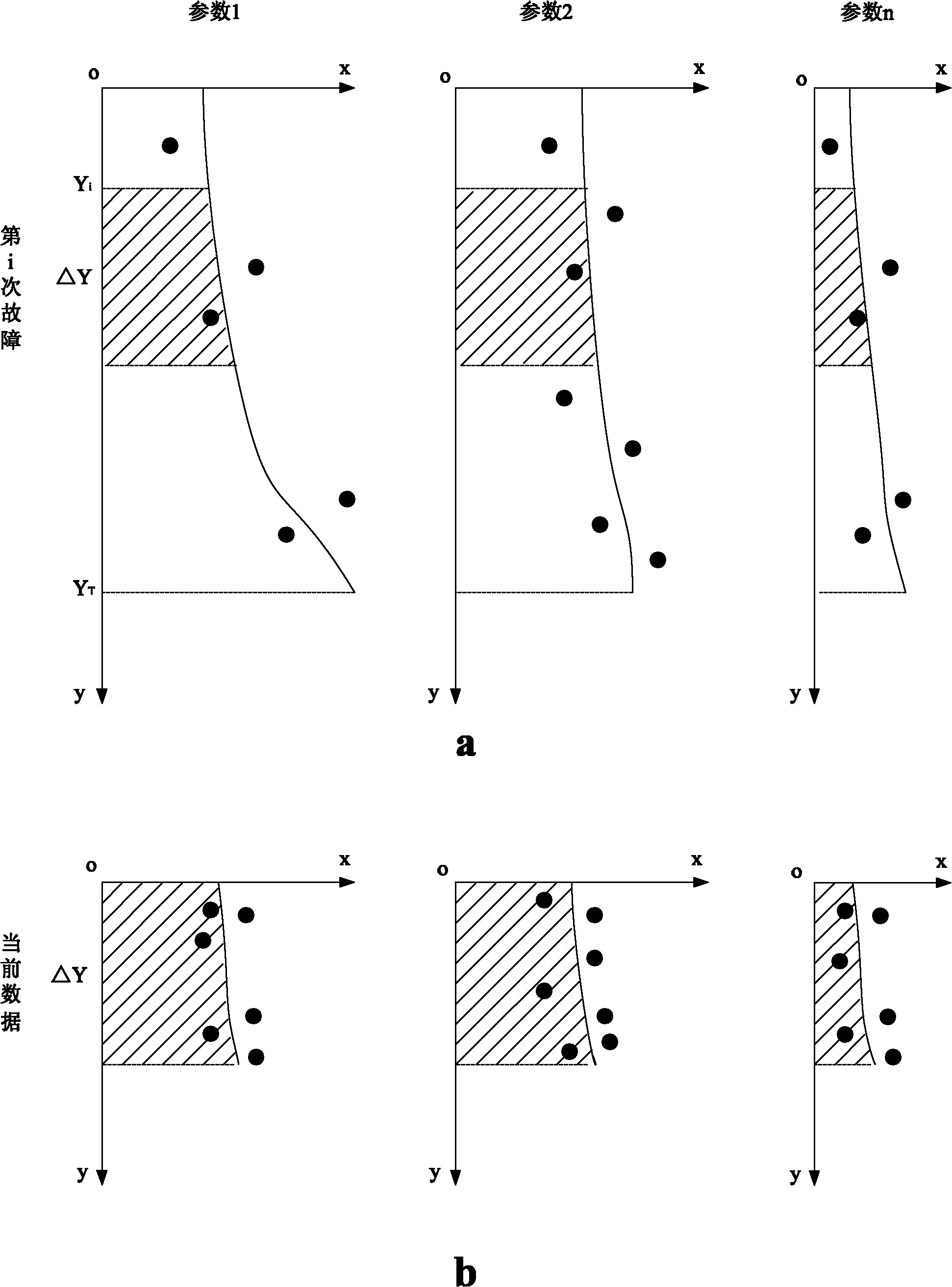

[0029] A method for predicting equipment faults based on point inspection data and DCS online data, characterized in that an equipment maintenance information database is established, and the maintenance information database includes equipment point inspection data, DCS online data and equipment maintenance data, and the Equipment point inspection data and DCS online data are stored in association with equipment maintenance data; and then periodically match the data in the current stage of the equipment with the data in the maintenance information database. When the maintenance data of a certain maintenance match, the equipment is predicted to predict the type of failure and the time of failure according to the data in the maintenance information database; the point inspection data refers to the point inspection and / or inspection process of the equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com