Injector

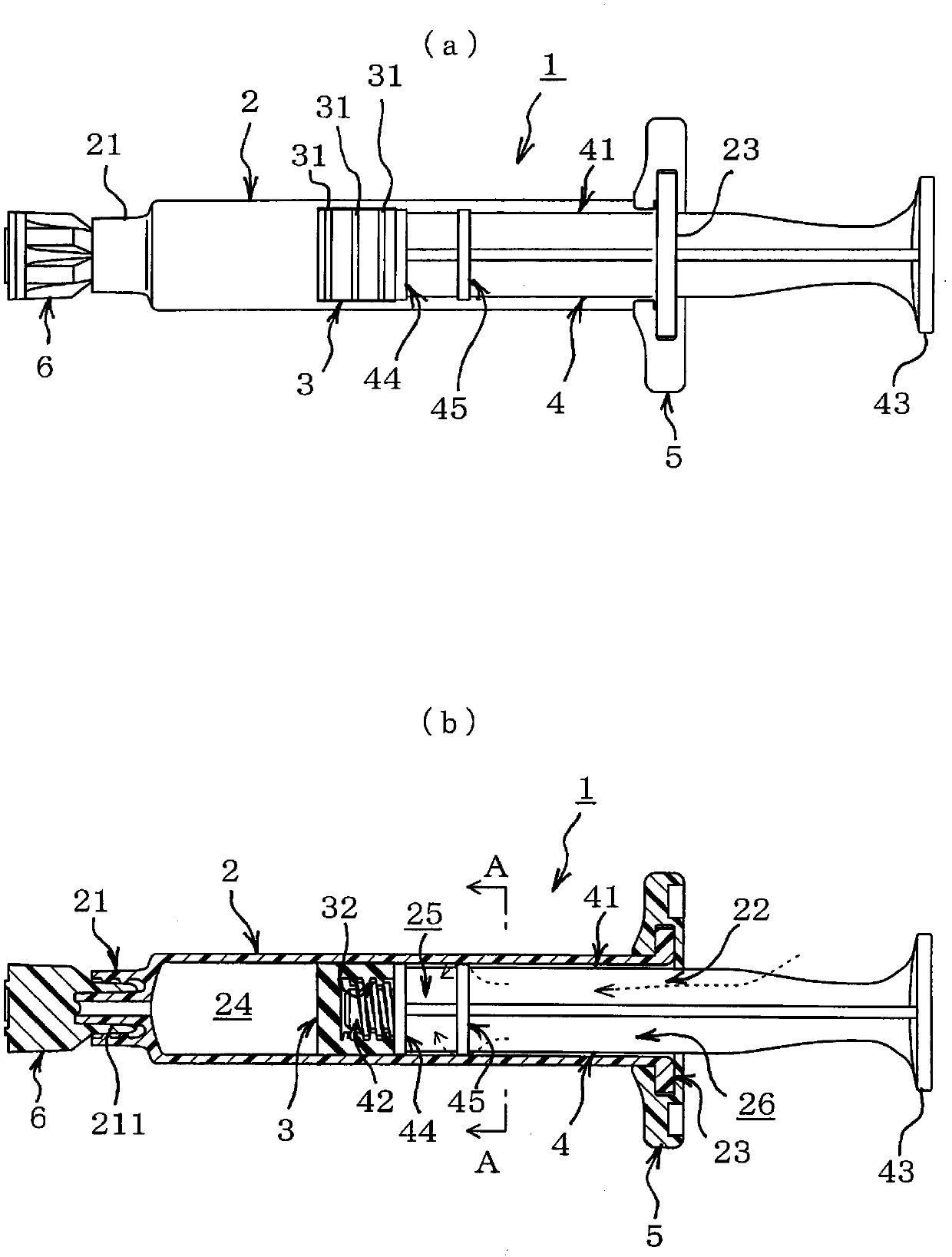

A technology for syringes and syringes, applied in the field of syringes, which can solve problems such as insufficient sterilization and difficulty in entering hydrogen peroxide gas, and achieve the effects of ensuring airtightness, functional reliability, and increased reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

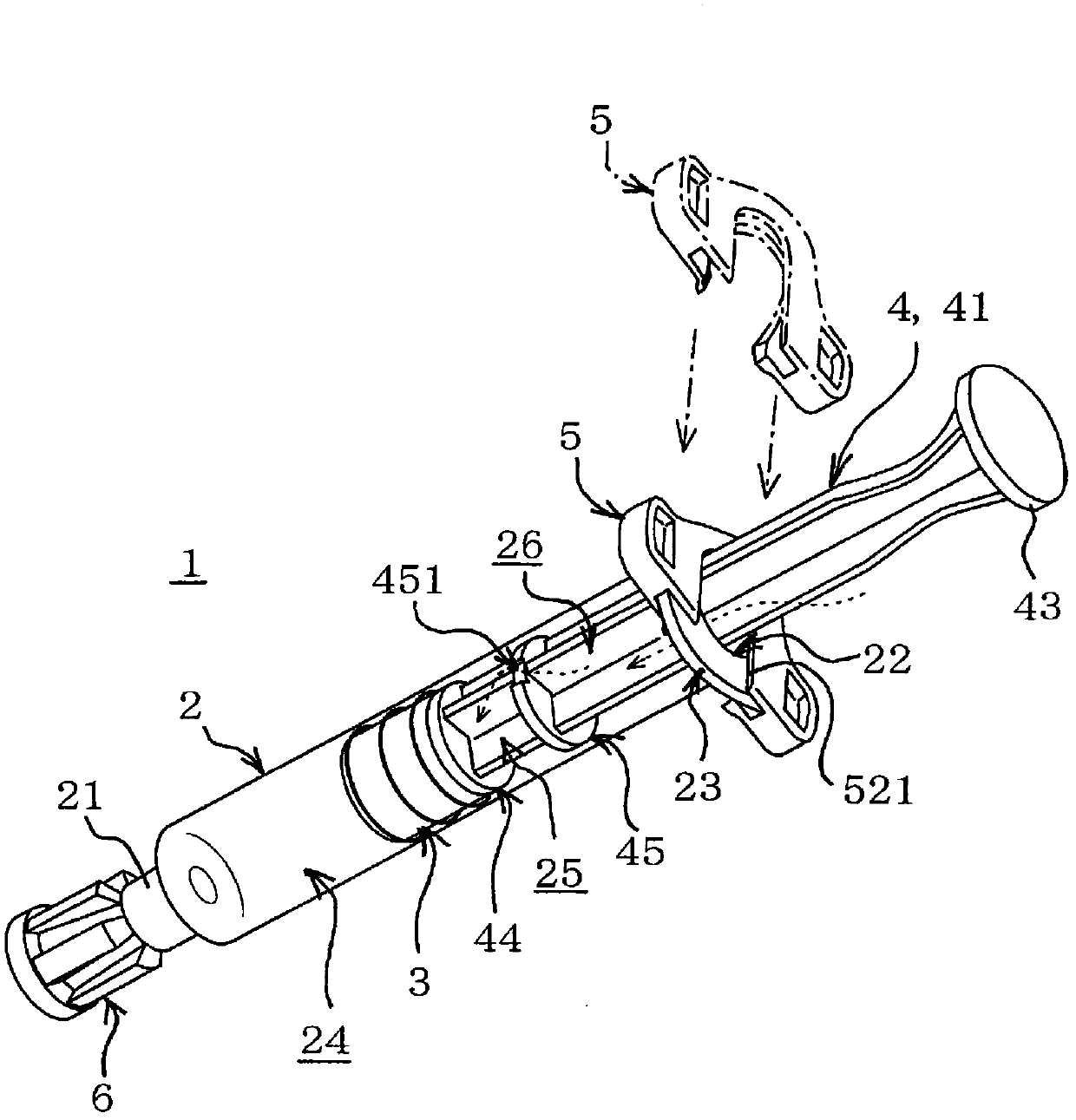

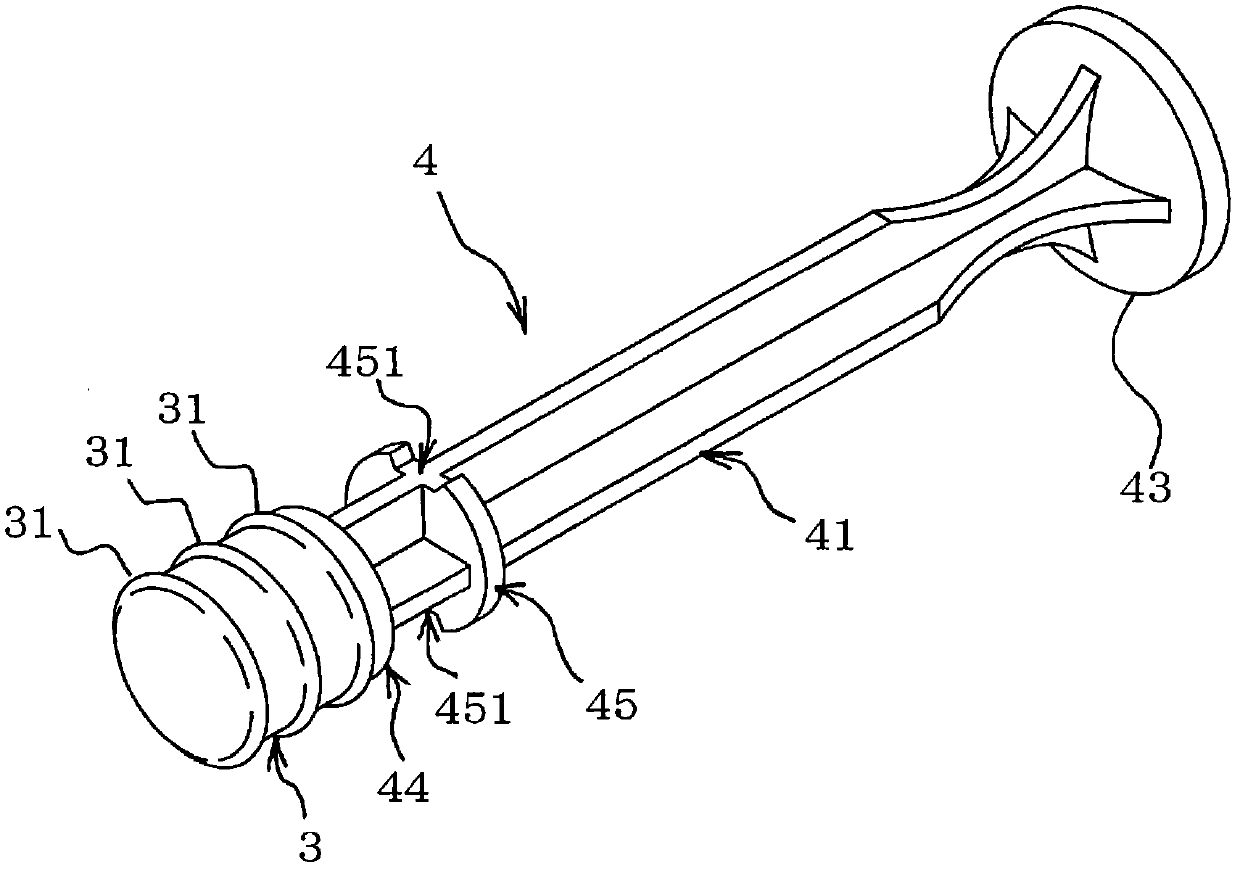

Embodiment approach

[0035] In addition, the present invention is not limited to the above-described embodiments, and includes other various embodiments. That is, in the above-mentioned embodiment, as the circulation opening formed on the disk portion 45, the following is shown: Figure 4 The groove-shaped communication openings 451, 451 shown, but as shown below, in the range that can fully ensure the circulation of the sterilizing gas and can ensure that the disc portion 45 and the hole edge 521 of the finger hook 5 stop each other, Various shapes, arrangements, and numbers of flow openings can be selected. For example, as the flow opening for ensuring the flow of sterilizing gas, it is possible to use Figure 4 The through hole shown in reference numeral 452, Figure 7 The slit-shaped communicating opening shown by reference numeral 453 in (a), Figure 7 The opening of the notch shown by reference numeral 454 in (b) or Figure 8 The cutting part indicated by the reference number 455 in.

...

Embodiment

[0040]Carry out the test of carrying out final sterilization step respectively with respect to embodiment and comparative example and confirm the bactericidal effect of embodiment and comparative example by comparison. As the final sterilization process, the prefilled syringe is placed in a sterilization tank filled with hydrogen peroxide gas in a state in which it is housed in the package, and sterilization is performed by contacting it with hydrogen peroxide gas. Examples are prefilled syringes using the plunger rod 4 with the communication opening 451 described in the above-mentioned embodiments, and Comparative Examples are prefilled syringes using the plunger rod without the communication opening 451 . Here, the opening area of the communicating opening 451 in the embodiment is 1.1 mm. 2 .

[0041] In the sterilizing treatment of the final sterilizing process, the following packaging methods are used in the examples and the comparative examples. That is, a polyethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com