Printer device

A technology of a printing device and a printing head, applied in the directions of printing devices, printing, typewriters, etc., can solve problems such as obstruction of the cutting unit 530, and achieve the effect of improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

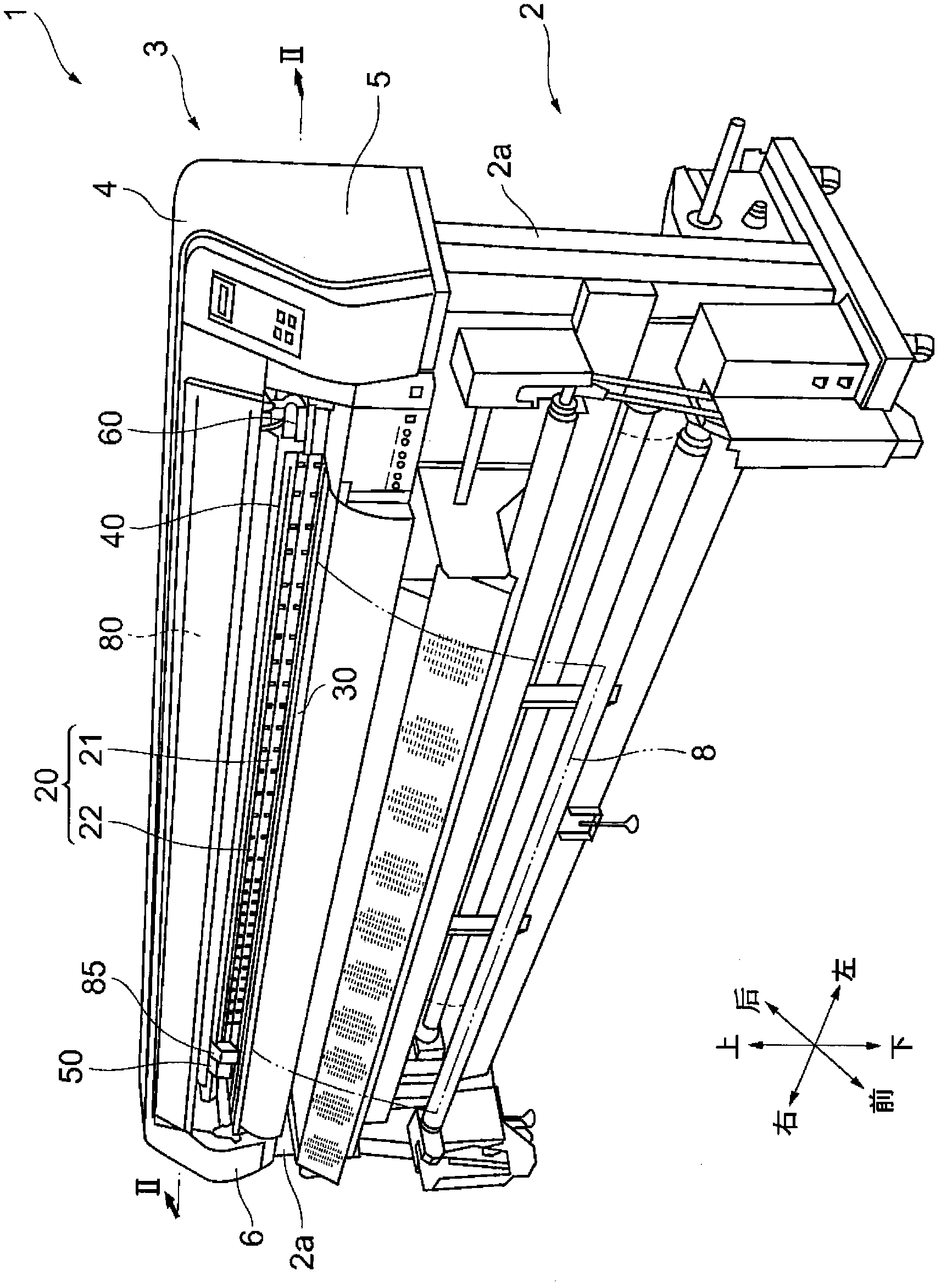

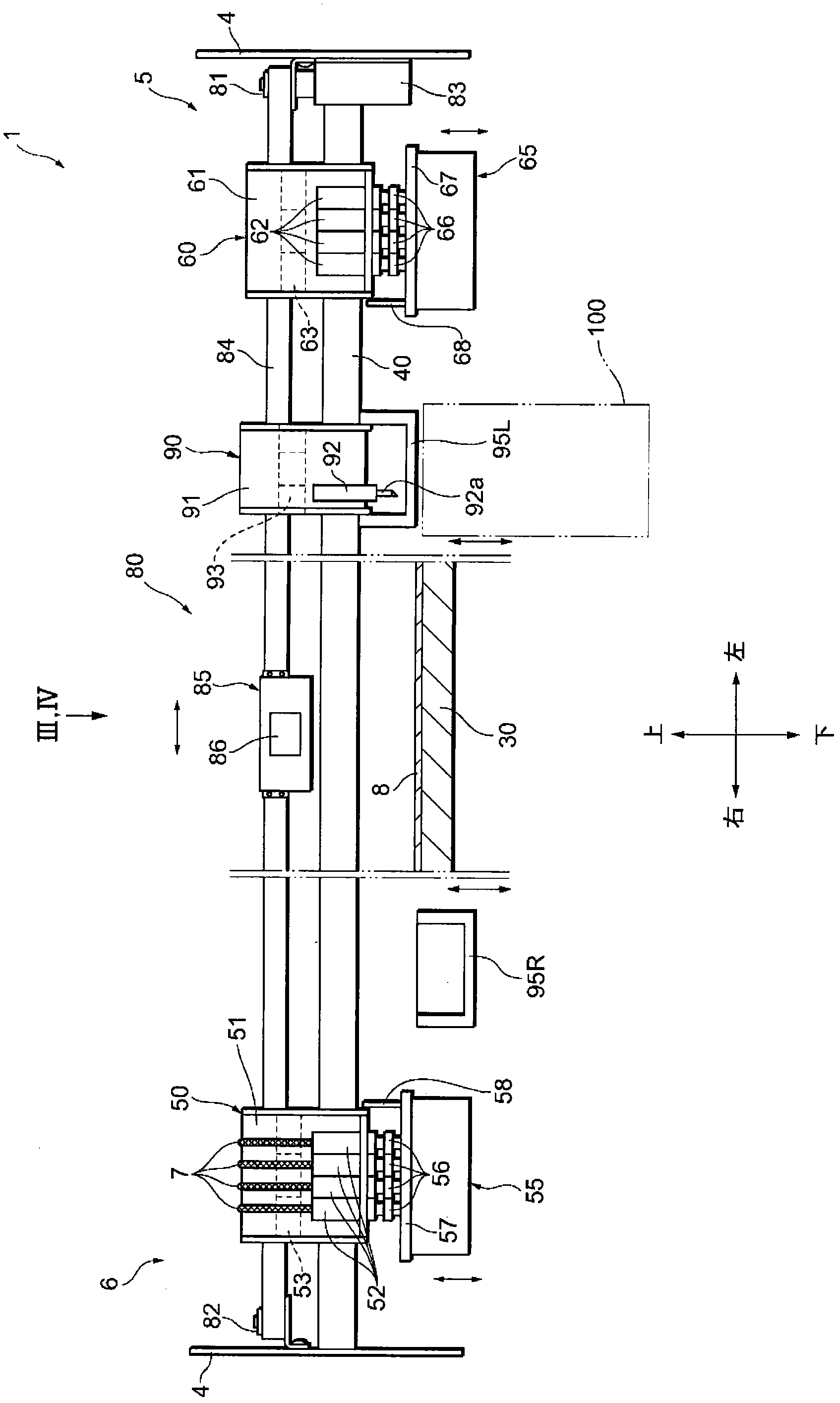

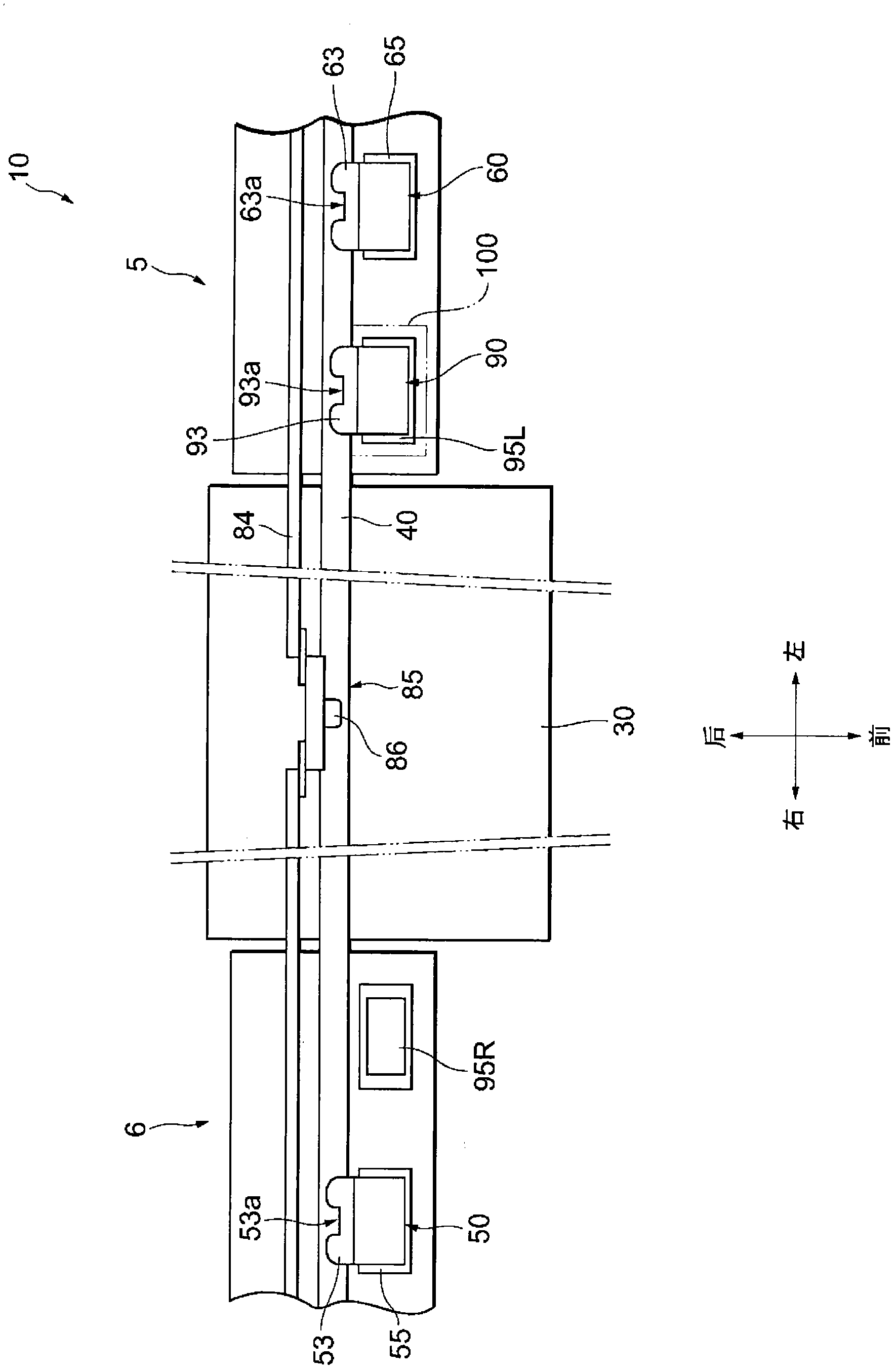

[0069] refer to Figure 1 to Figure 7 The configuration of the printing apparatus 1 of the first embodiment will be described. figure 1 shows a perspective view of the printing device 1, figure 2 and image 3 Indicates the vicinity of the guide rail 40 described later, Figure 4 It shows the plan view of the unit drive device 80 mentioned later, Figure 6 A cross-sectional view showing a connection portion between the drive carriage 85 and the connection portion 53 (the connection portion 63 and the connection portion 93 ), which will be described later, Figure 6 and Figure 7 The vertical movement mechanism 100 mentioned later is shown.

[0070] Such as figure 1 As shown, the printing device 1 is mainly composed of a main body 3 extending in the left-right direction, and a support part 2 for supporting the main body 3 and having a pair of left and right legs 2a, 2a. A left main body 5 and a right main body 6 are respectively formed on left and right ends of the main ...

Embodiment 2

[0098] Below, refer to Figure 8 and Figure 9 , the vertical movement mechanism 150 as another embodiment of the vertical movement mechanism 100 in the printing apparatus 1 of the first embodiment described above will be described. The same reference numerals are assigned to the members already described in the first embodiment above, and description thereof will be omitted. in addition, Figure 8 Indicates the state in which the cutting unit 90 is held by the left standby stage 95L, Figure 9 A state in which the cutting unit 90 moves downward and retreats is shown.

[0099] like Figure 8As shown, the vertical movement mechanism 150 is mainly composed of a vertical support member 151 connected to the left standby stage 95L and extending in the vertical direction, a left and right support member 152 connected to the bottom of the vertical support member 151 and extending in the left-right direction, A fixed support table 160 fixed to a frame member such as the leg 2 a o...

Embodiment 3

[0105] Below, refer to Figure 10 and Figure 11 The vertical movement mechanism 200 as another example of the vertical movement mechanism 100 of the printing apparatus 1 according to the first embodiment will be described. The same reference numerals are assigned to the members already described in the first embodiment above, and description thereof will be omitted. in addition, Figure 10 Indicates the state in which the cutting unit 90 is held by the left standby stage 95L, Figure 11 A state in which the cutting unit 90 has moved downward and retracted is shown.

[0106] like Figure 10 As shown, the up and down moving mechanism 200 is composed of an air cylinder 220 , the upper end of the cylinder rod 221 is installed on the left standby stage 95L, and the cylinder main body 222 is fixed in the fixed support platform 210 . According to this structure, in the state where the cutting unit 90 is held by moving the left standby stage 95L upward by the vertical movement m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com