Linear actuator

A technology of linear actuators and actuating elements, applied in the direction of transmission, belts/chains/gears, mechanical equipment, etc., can solve expensive and difficult problems, and achieve simple and cheap solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

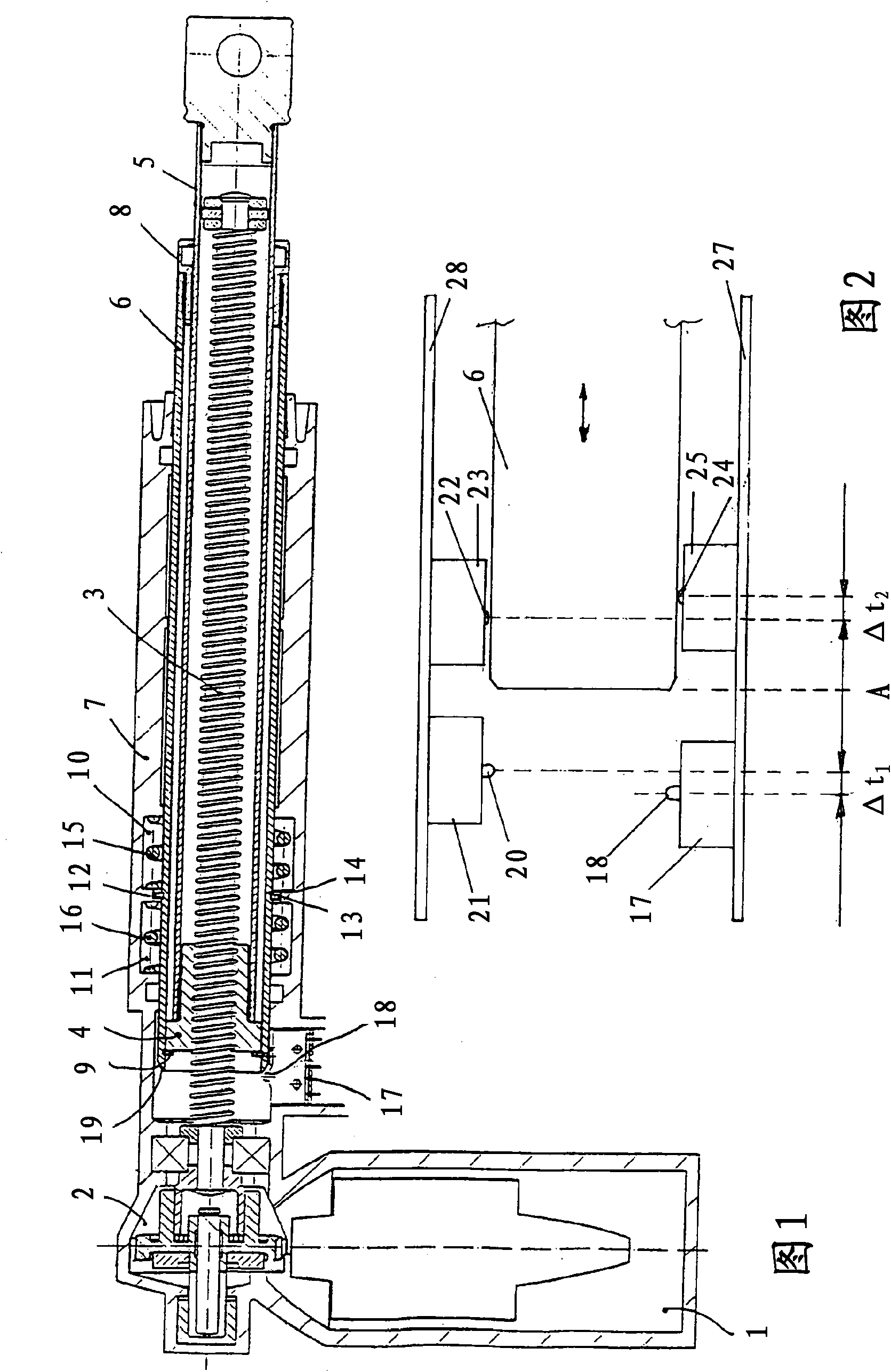

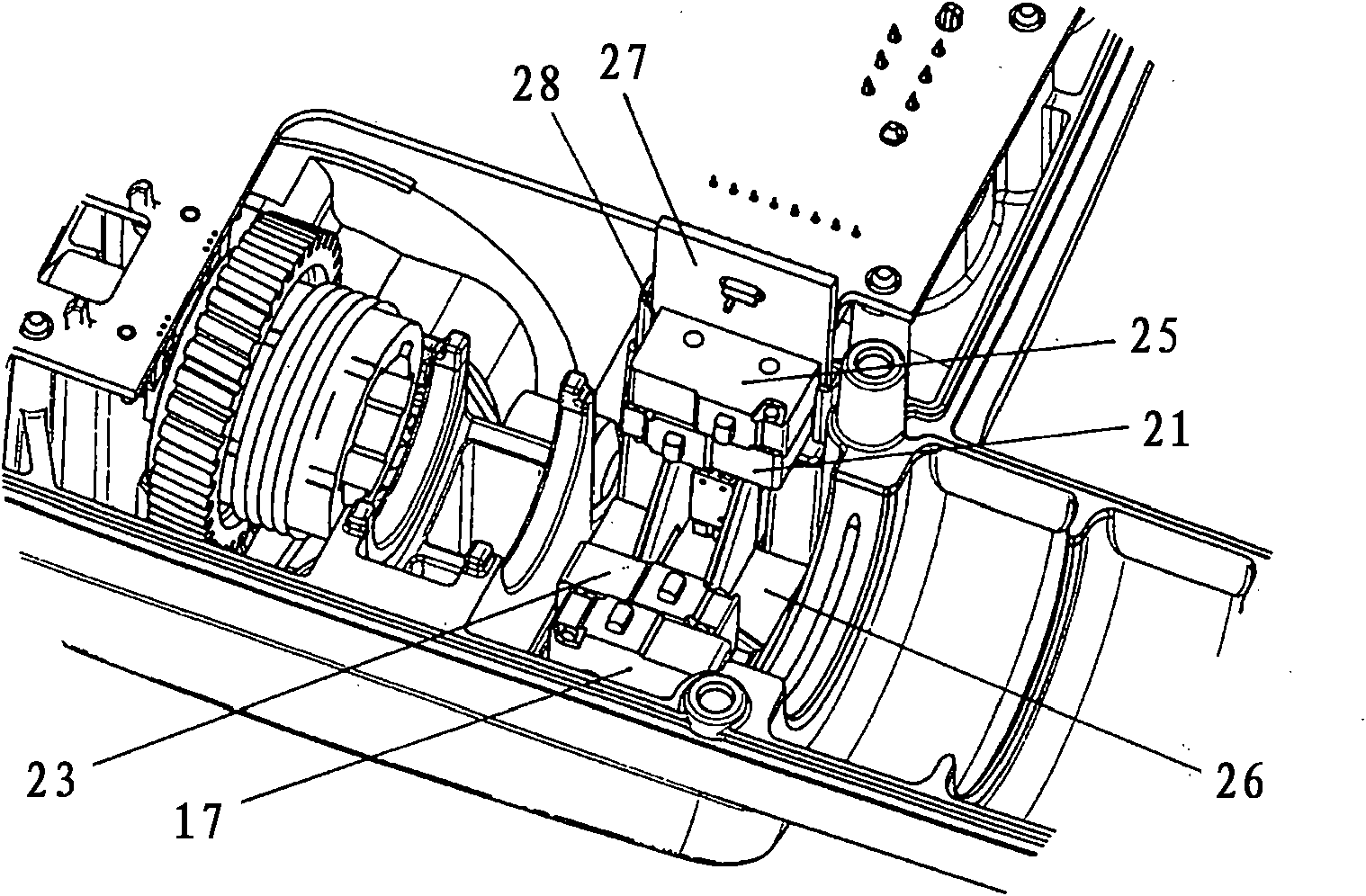

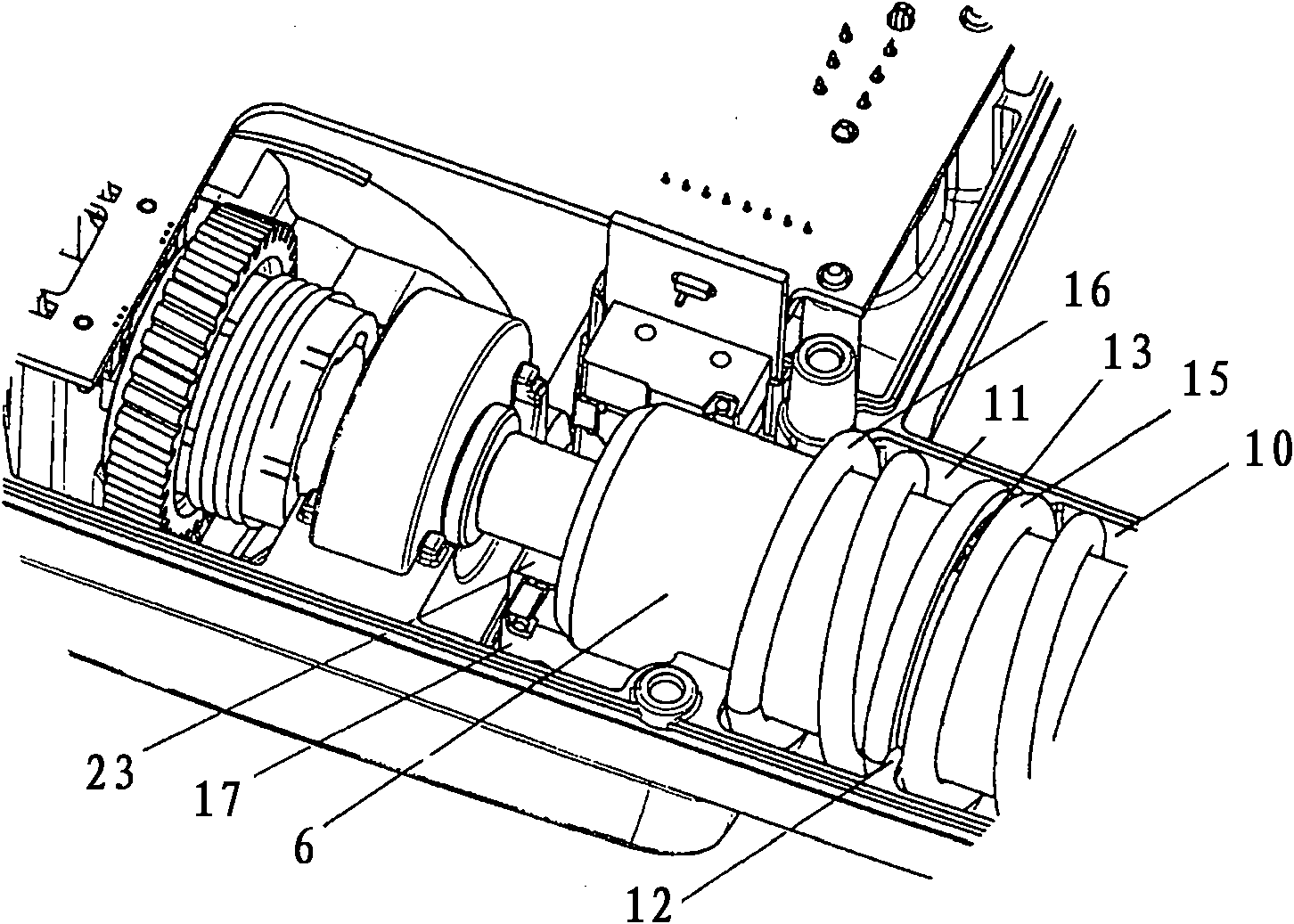

[0020] figure 1 A longitudinal section through a linear electric actuator is shown, basically comprising a DC low voltage electric motor 1 driving a spindle with a spindle nut 4 via a transmission 2 3. Mounted on the spindle nut 4 is a tubular shaped actuating element 5 equipped with a fixing at one end for mounting the actuator on the machine. When the fixture is mounted on the machine, the spindle nut 4 is fixed against rotation, so the spindle nut is moved outwards or inwards by the rotation of the spindle 3 depending on the direction of rotation of the spindle 3 . The spindle nut 4 and the actuating element 5 mounted on it are guided in a surrounding outer tube 6 which is equipped with a guide bush 8 at its free end. One end of the outer tube 6 is axially movably embedded in the housing 7 of the actuator. The outer tube 6 is internally equipped with a retaining ring 9 at its end protruding into the housing 7 . When the spindle nut 4 encounters the ring 9 during its run...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com