Temperature control within disk drive testing systems

A disk drive, test slot technology, used in temperature control, non-electric variable control, control/regulation systems, etc., to solve problems such as disk drive safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0175] System Overview

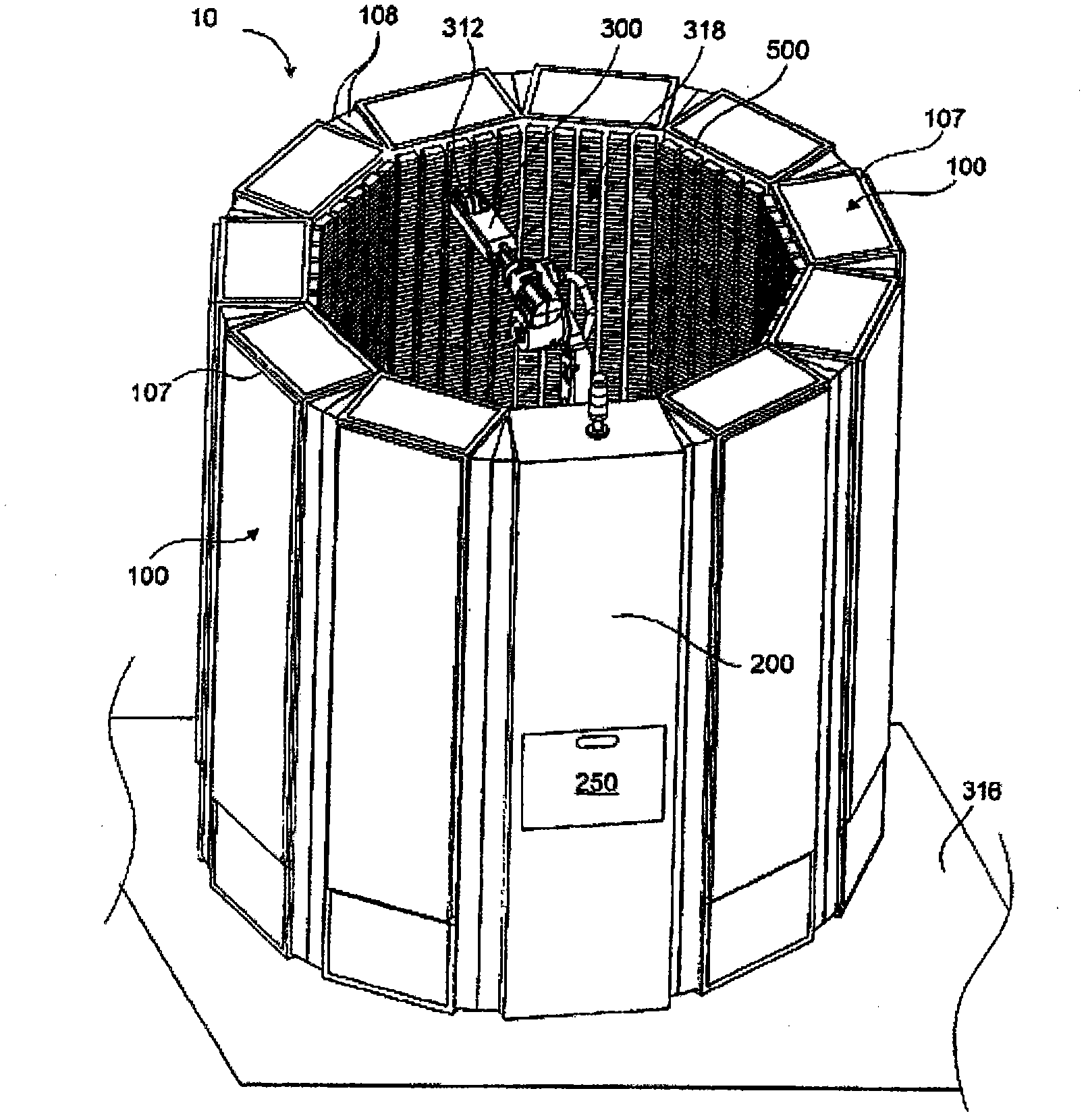

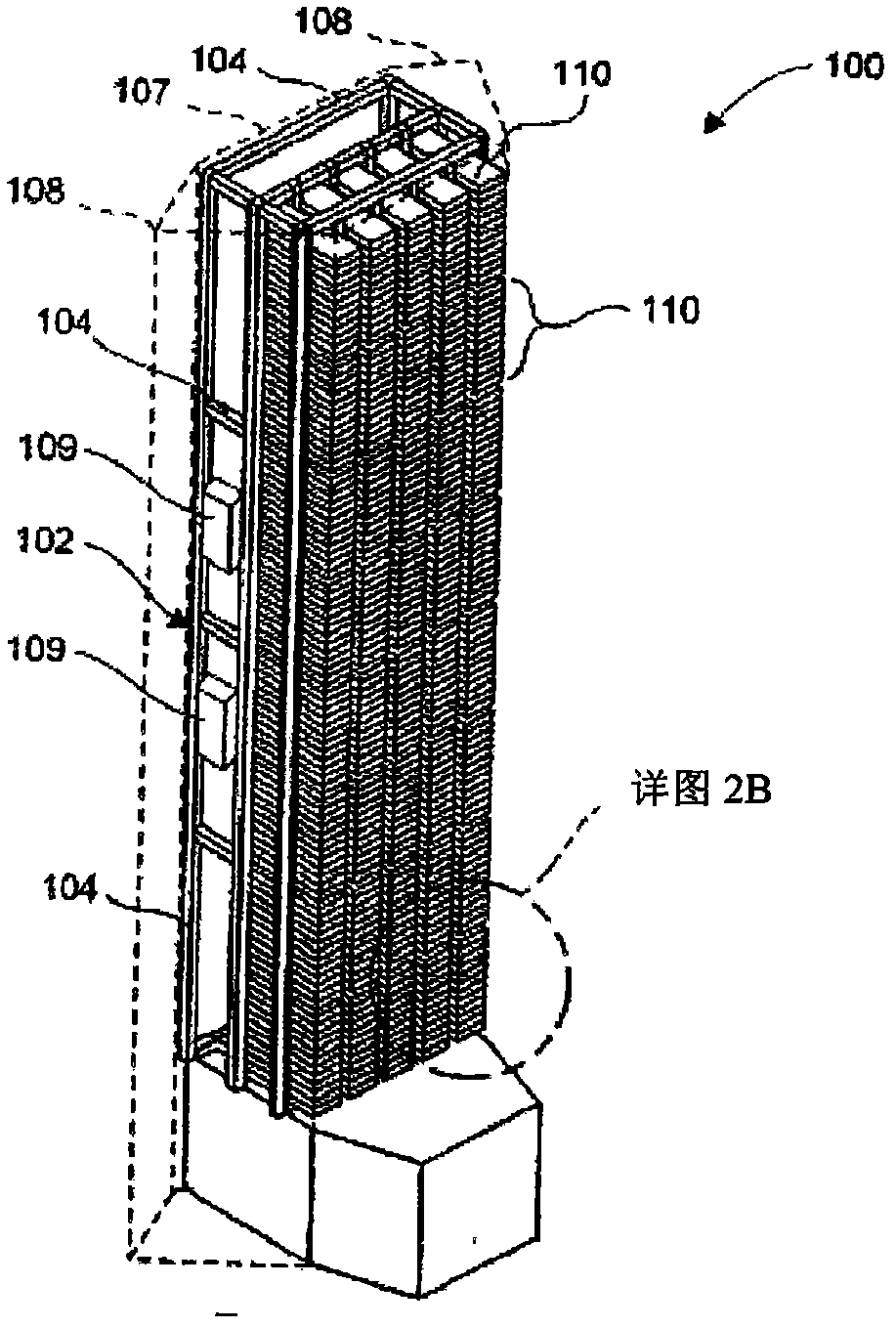

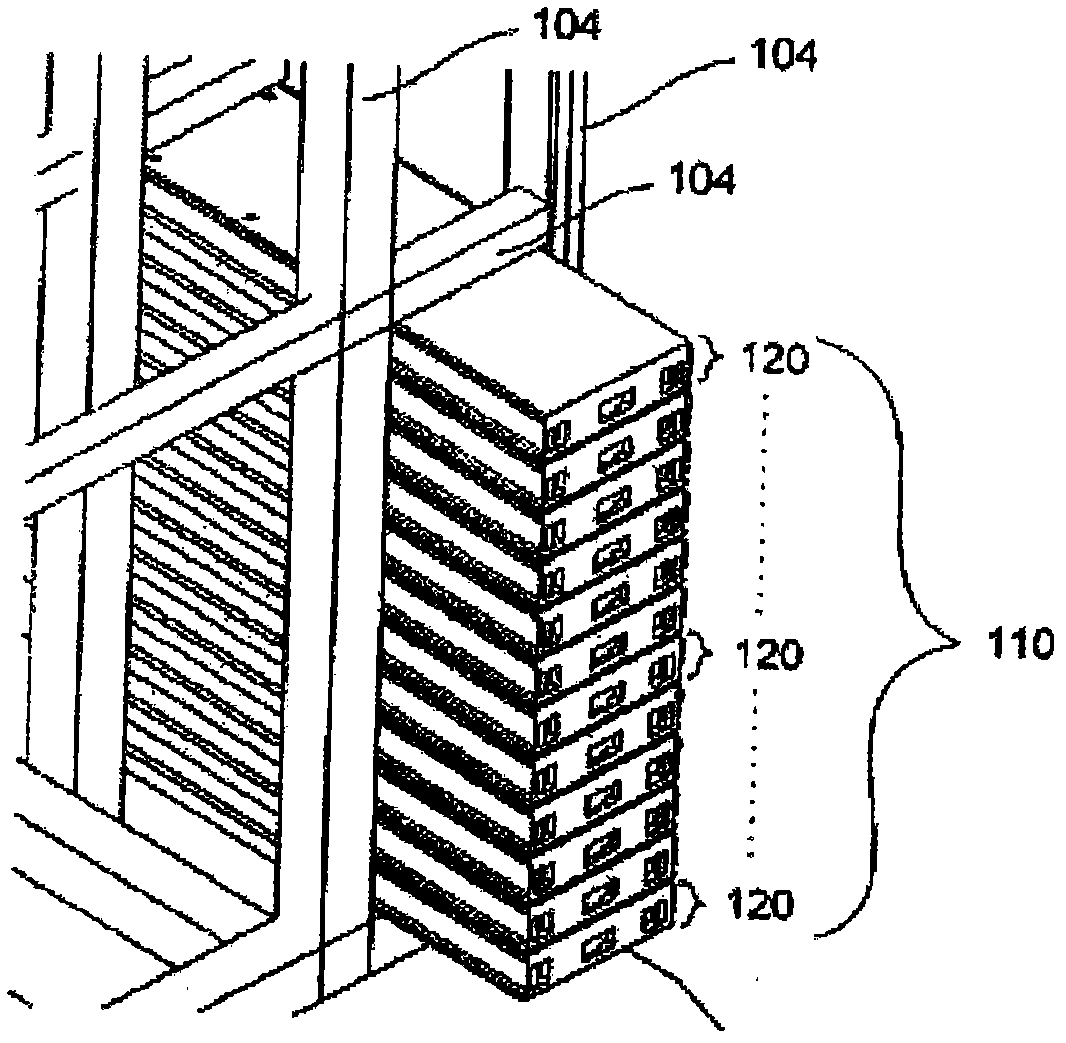

[0176] Such as figure 1 As shown, the disk drive testing system 10 includes a plurality of test racks 100 (eg, ten test racks are shown), a transfer station 200 , and a robot 300 . Such as Figure 2A and Figure 2B As shown, each test rack 100 generally includes a base 102 . The base 102 may be constructed from a plurality of structural members 104 (eg, aluminum extrusions, steel pipes, and / or assemblies) fastened together and together defining a plurality of socket sets 110 . Each socket set 110 can support a plurality of test socket assemblies 120 . refer to Figure 2A , the test stand 100 may also include a body 107 (e.g., formed from one or more sheet metal and / or molded plastic parts, see also figure 1 ), which at least partially seals the base 102. The body 107 can include a wedge portion 108 that can be used to separate power supply electronics 109 (eg, an AC to DC power supply). Such as image 3 As shown, each test slot assembly 120 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap