Machine and method for automated detection of cables, wires and profiles in or on cable processing machines

An automatic detection and processing machine technology, which is applied in the direction of cable installation, disassembly/armored cable equipment, cable installation device, etc., can solve the problems of measuring machine complexity and achieve the effect of optimizing the processing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

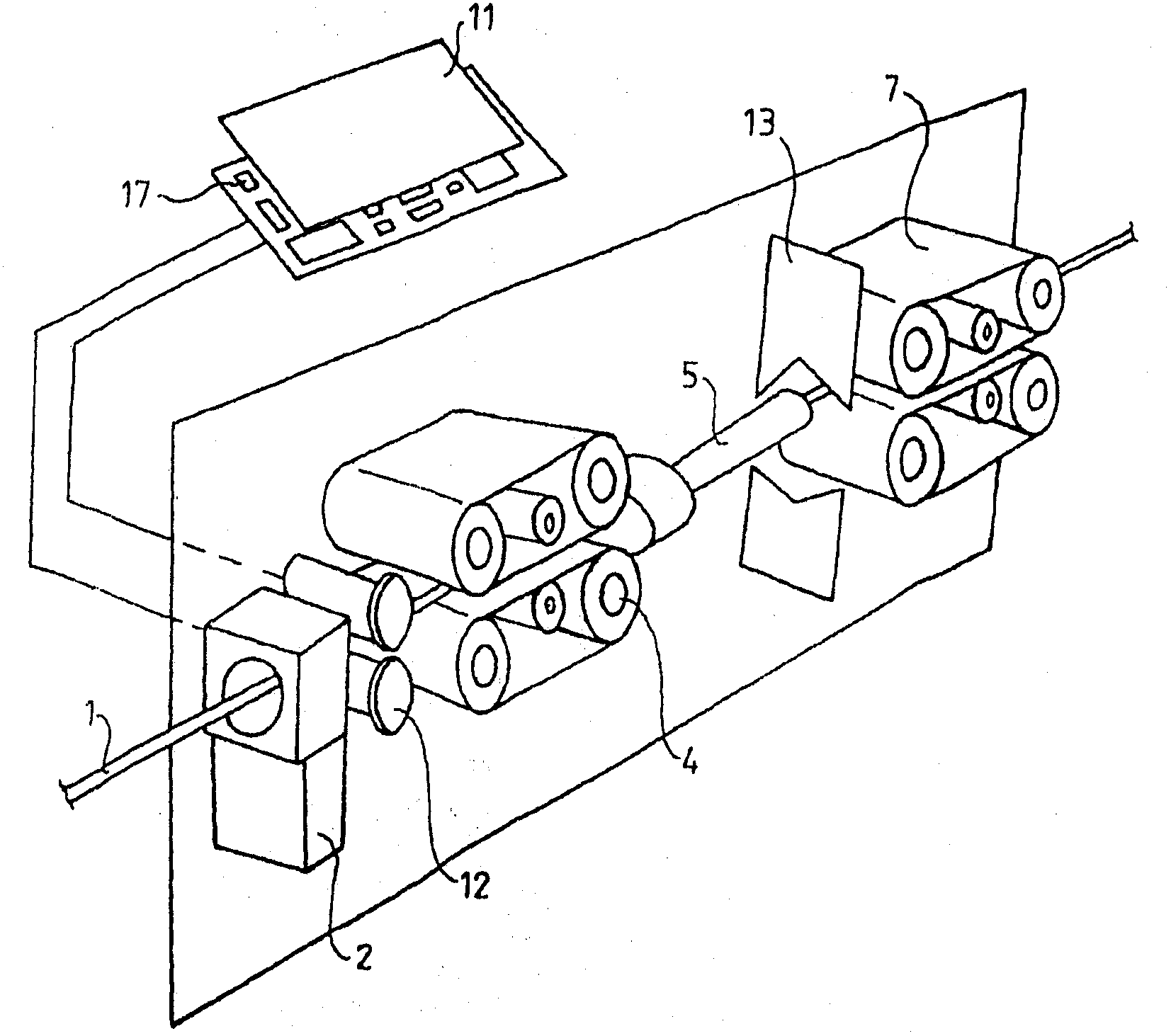

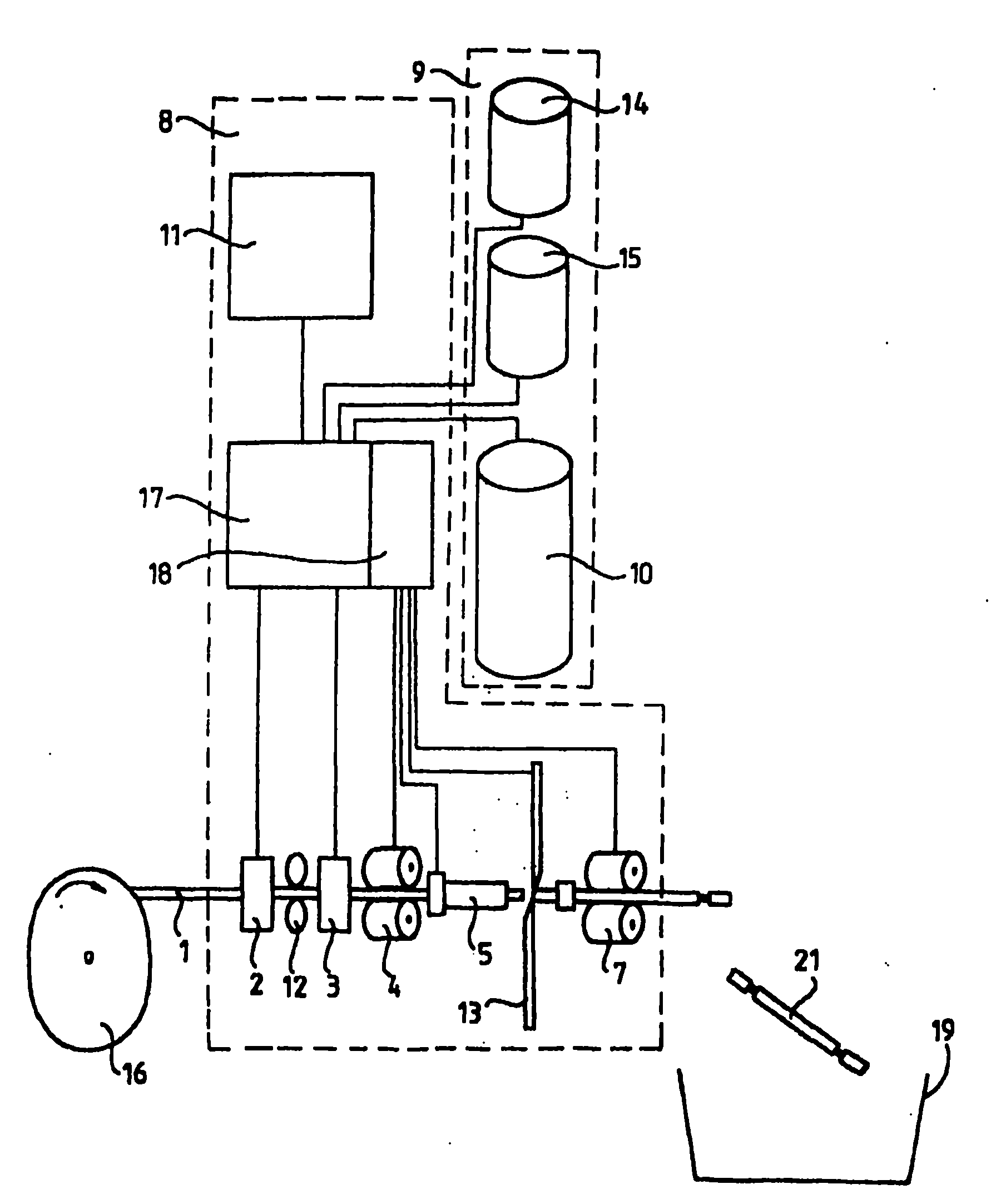

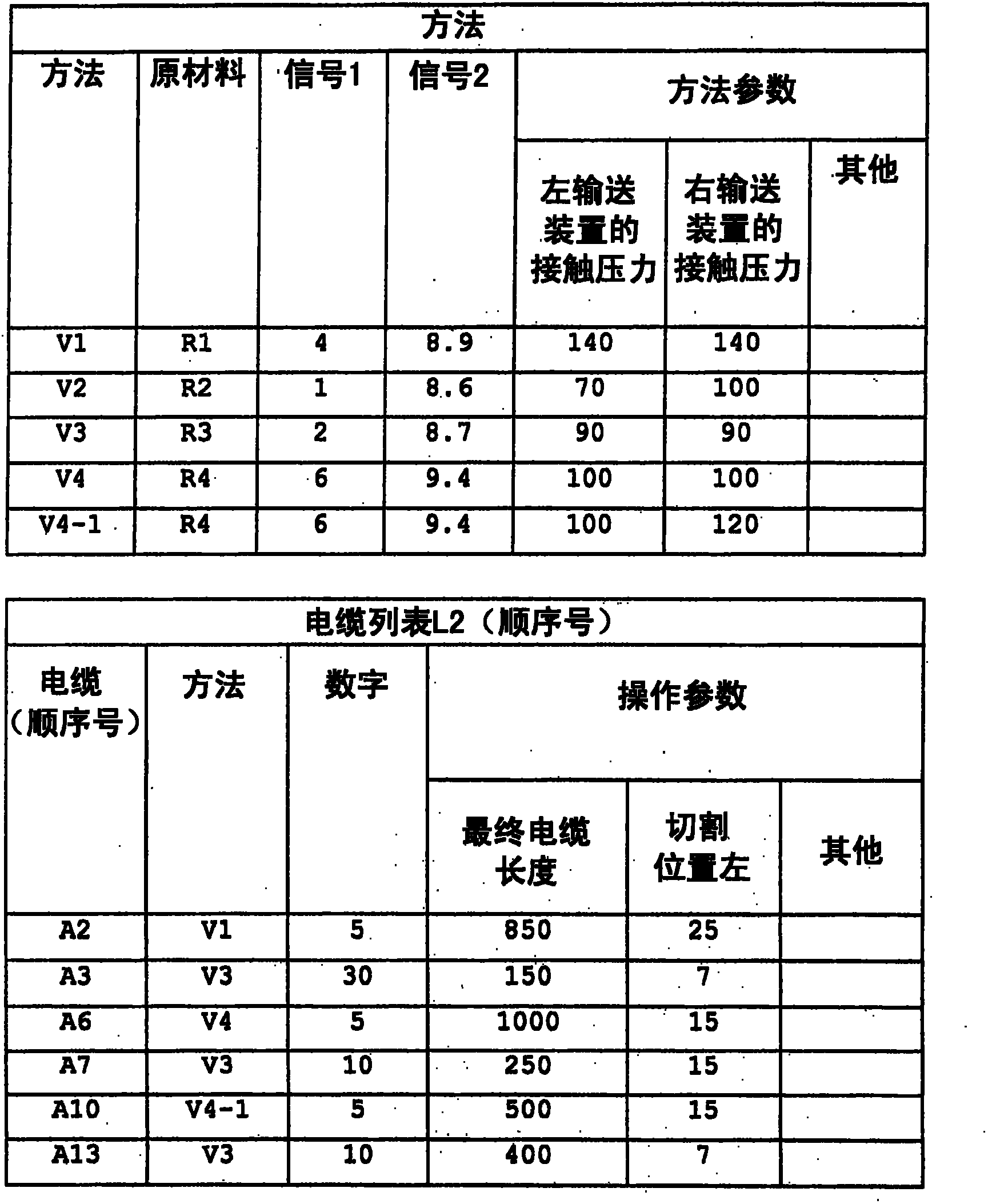

[0130] Full description is provided for the accompanying drawings. The same reference numerals represent the same components. The scope of protection of the claims is not limited to the examples shown. Therefore, cable processing machines with multiple pairs of tools or the like are also included.

[0131] With the non-contact sensor 2, an excitation signal is generated and induced in the cable 1 being processed. The signal response from the cable 1 produces a measurement signal which will lead to conclusions about the internal structure of the at least partly metal-containing cable, wire or rolled profile 1 (hereinafter "cable") to be processed by the cable processing machine. According to a particular embodiment of the invention, the sensor 2 is preferably an inductive bell sensor consisting essentially of a transmit / receive coil and an evaluation circuit.

[0132] According to a specific modification of the embodiment, a commercially available bell sensor 2 (manufacturer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com