Noise reduction protective device for laminating machine

A protective device and film coating technology, applied in the direction of non-rotational vibration suppression, etc., can solve the problems of unbalanced transfer roller, loud noise, foaming on the surface of the paper, etc., to prevent unbalanced rotation, reduce violent vibration, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

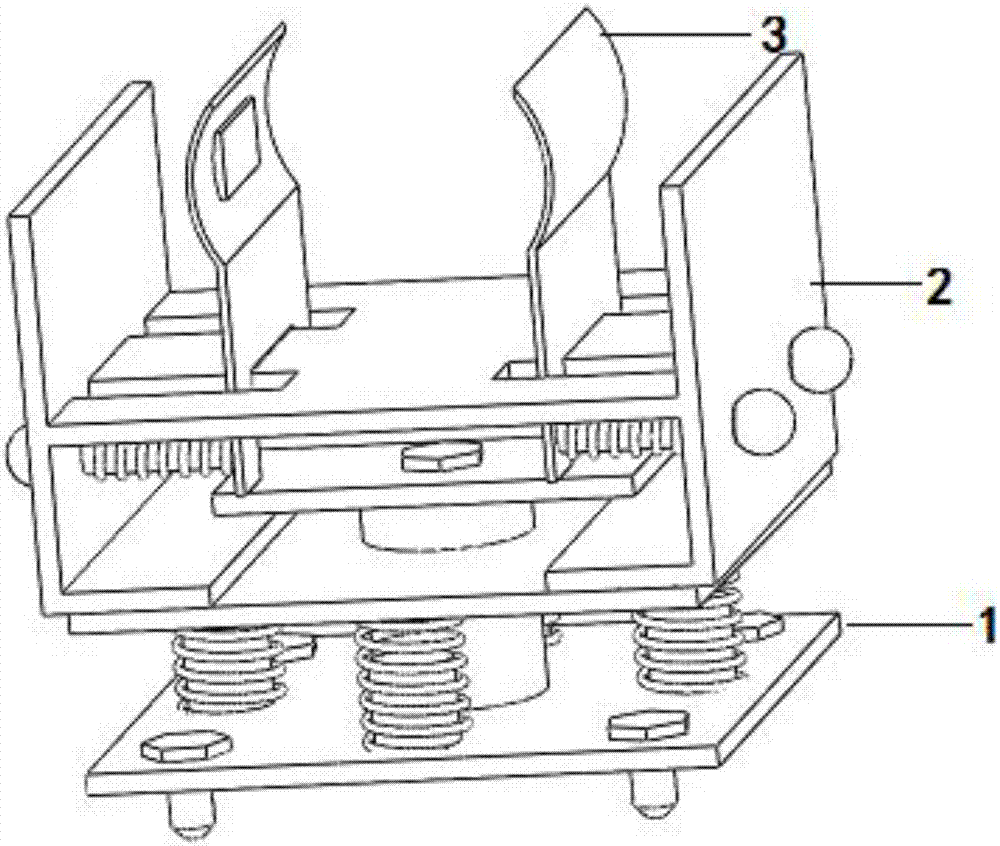

[0025] A protective device for noise reduction of a laminating machine, such as figure 1 As shown, it includes a protective fixing mechanism 1 fixed in the laminating frame body, a supporting mechanism 2 is installed on the protective fixing mechanism 1, a buffer clamping mechanism 3 is installed on the supporting mechanism 2, and a laminating machine is installed on the supporting mechanism 2. The motor, the motor of the laminating machine is clamped and fixed by the buffer clamping mechanism 3;

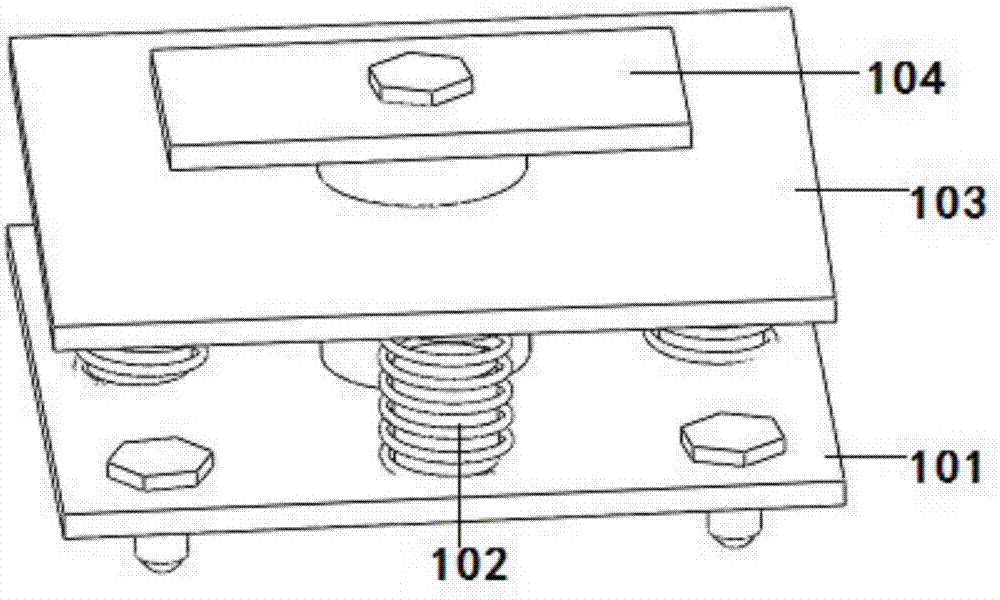

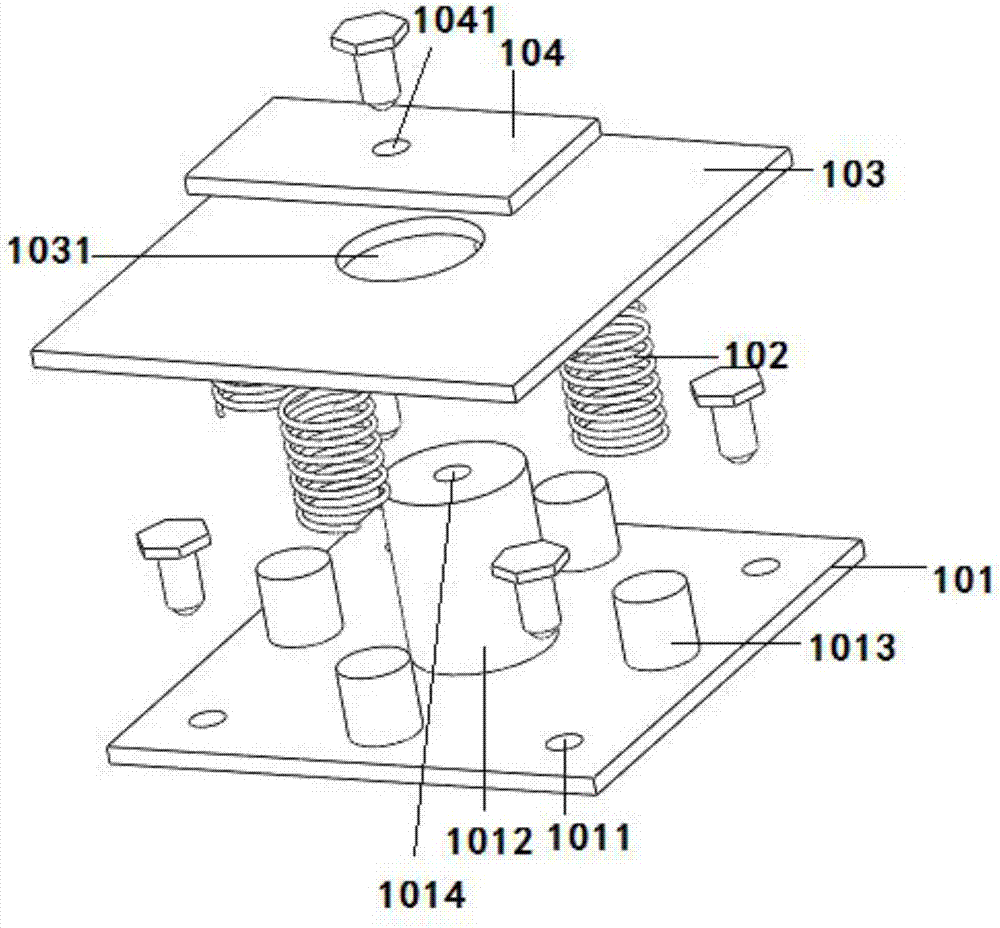

[0026] Such as figure 2 , image 3 As shown, the protection fixing mechanism 1 includes a fixed plate 101, a spring 102, a guide support plate 103 and a clamping plate 104 that are fixedly connected in sequence from bottom to top. The fixed plate 101 is fixed on the laminating frame body, and the fixed plate 101 There are first threaded through holes 1011 at the four corners of the surface, and the fixing plate 101 is fixed in the film-covering frame body through the first thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com