Spring chuck assembly of spinning winder

A spring collet and winding machine technology, which is applied to the clustering of newly extruded filaments, textiles and papermaking, etc., can solve the problems that affect the safety and efficiency of work, the fixing of the rotating shaft is not convenient, and the cushioning performance is not good, etc., to achieve Wide range of use, material saving, good stability and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

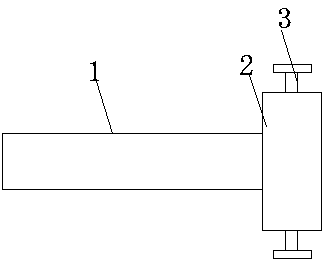

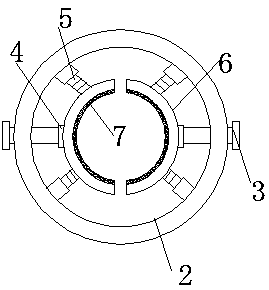

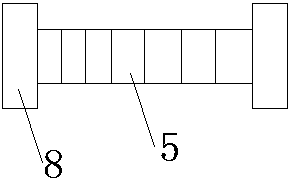

[0021] see Figure 1-5 As shown, a collet assembly of a spinning winding machine includes a main shaft 1 and a collet 2. Both sides of the collet 2 are connected with an inner ring 6, and one side of the inner ring 6 is connected to the collet 2. Several extrusion springs 5 are installed between them, both ends of the extrusion spring 5 are respectively connected to the inner ring 6 and the collet 2 through the bolt head 8, and the middle side of the inner ring 6 is connected to the collet 2 through the fastening bolt 3, and the working After the two ends of the intermediate shaft are installed inside the collet 2, it is more stable, and the installation and disassembly are convenient. The rotating shaft is inside the collet 2, screw the fastening bolt 3, the squeeze spring 5 pushes the inner ring 6 into close contact with the outside of the rotating shaft, at the same time, the fastening bolt 3 can push the inner ring 6 to move, and the two inner rings 6 from both sides Th...

Embodiment 2

[0023] Additionally, according to Figure 1-5 As shown, the difference between it and the above-mentioned embodiment is that a bearing 4 is installed at the joint between the fastening bolt 3 and the inner ring 6, and one end of the fastening bolt 3 penetrates the collet 2, and when the fastening bolt 3 is screwed, the fastening One end of the bolt 3 rotates inside the inner ring 6 through the bearing 4, the inner ring 6 will not rotate with the fastening bolt 3, but can move under the promotion of the fastening bolt 3. The inside of the inner ring 6 and the collet 2 are provided with several screw holes 9, and the bolt heads 8 are respectively connected to the inner ring 6 and the collet 2 through the screw holes 9. The compression spring 5 is more convenient to install and disassemble in use. The inside of the rubber pad 7 is uniformly provided with several anti-slip platforms 10, which can increase the friction between the rubber pad 7 and the rotating shaft, so that the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com