Kerf-improved tire used for automobile

A technology for cutting seams and automobiles, which is applied to road tires, tire parts, tire treads/tread patterns, etc., and can solve problems such as reduced cutting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

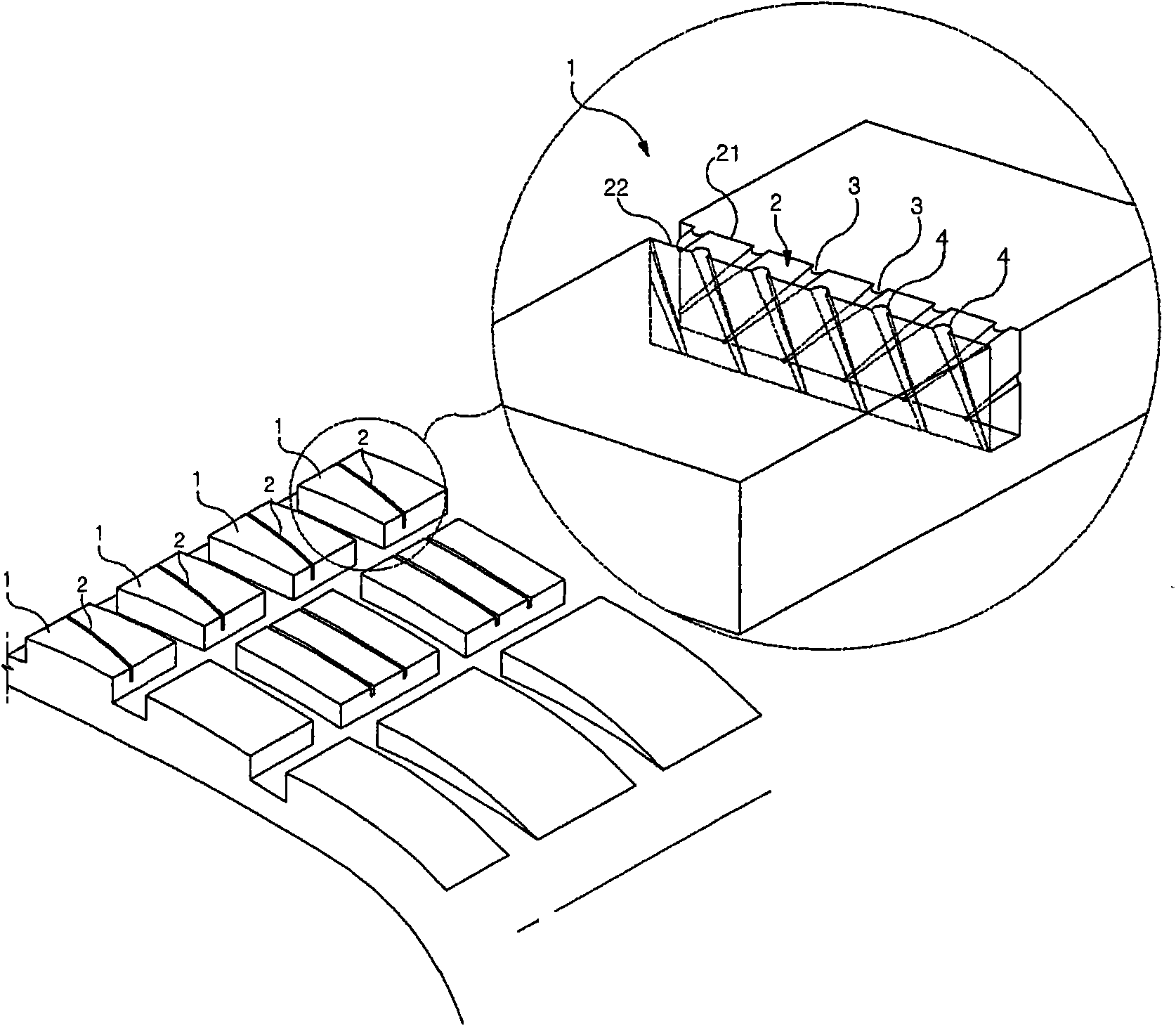

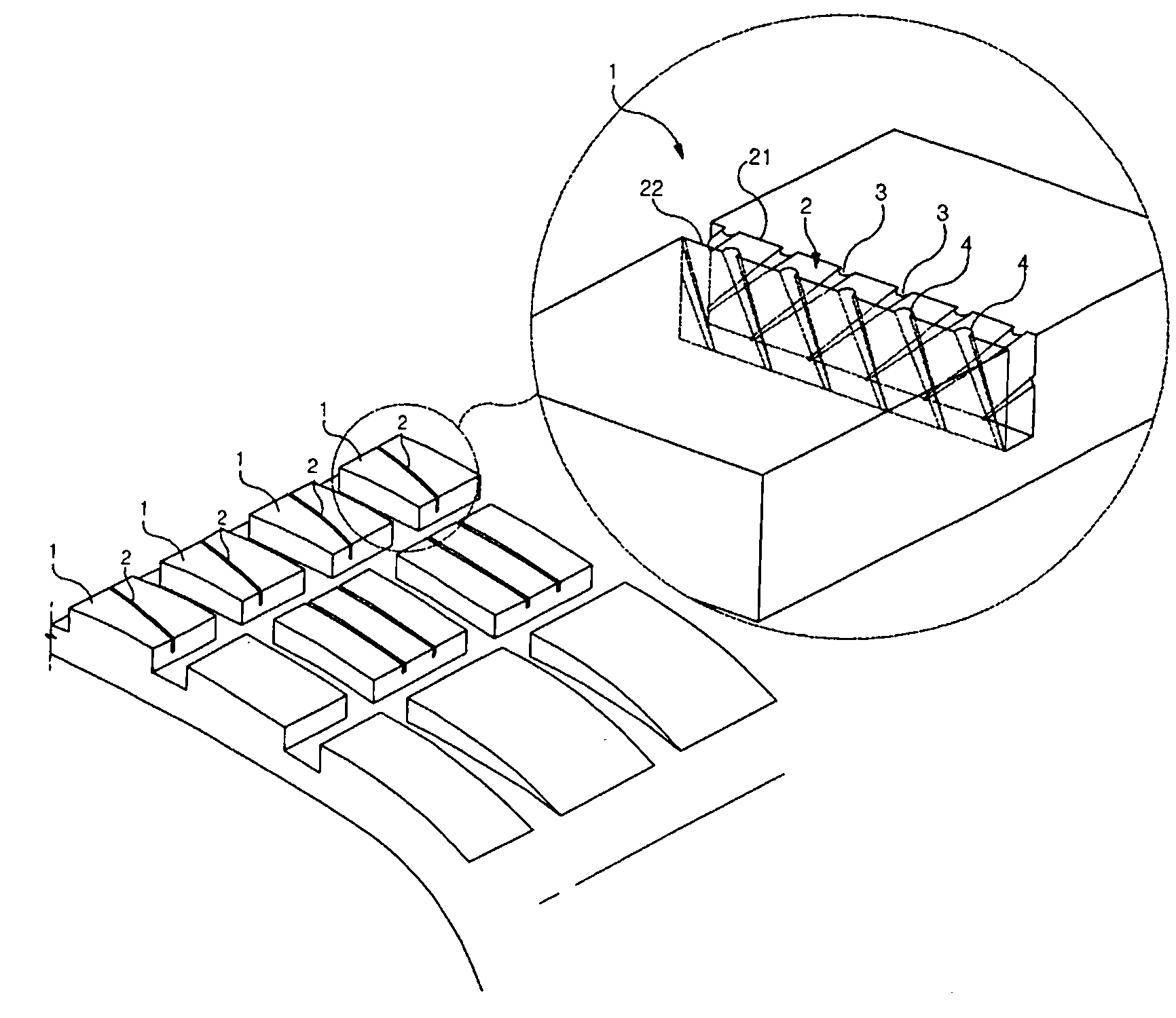

[0012] Below, the present invention is described more specifically according to the accompanying drawings, and its content is as follows.

[0013] The automobile tire of the present invention is composed of a tread portion, sidewall portions on both sides of the tread portion, and spherical portions at both ends of the sidewall portion. A block 1 is formed on the contact surface of the tread portion, and a slit 2 is formed on the block 1 . In addition, inclined protrusions 3, 4 are formed on the wall surface of the slit 2. As shown in FIG.

[0014] In the present invention, the inclined protrusions 3, 4 formed on the wall surface of the slit 2 are on the two wall surfaces 21, 22 of the slit 2, starting from the upper section of the slit 2, not in the axial or vertical direction, but along the The downwardly inclined directions are respectively protrudingly formed.

[0015] In addition, in the present invention, the above-mentioned inclined protrusions 3 , 4 provided on the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com