Stern tube bush unit

A technology for stern tubes and bushings, which is applied in the direction of engine components, transmission devices with synchronous propulsion components, engine seals, etc., can solve the problems of reducing the space utilization rate of the rear side of the hull and increasing the overall length of the hull, etc., to achieve Improved assembly quality, easy installation, and improved assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

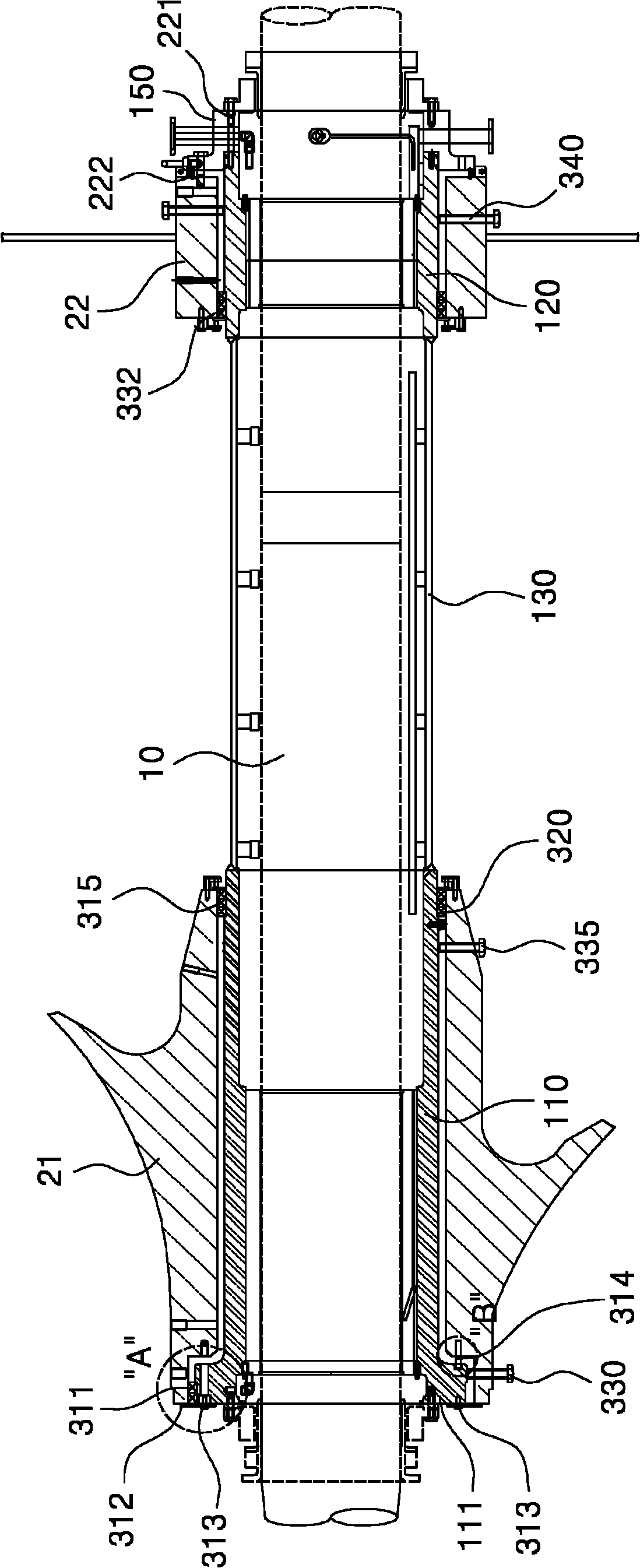

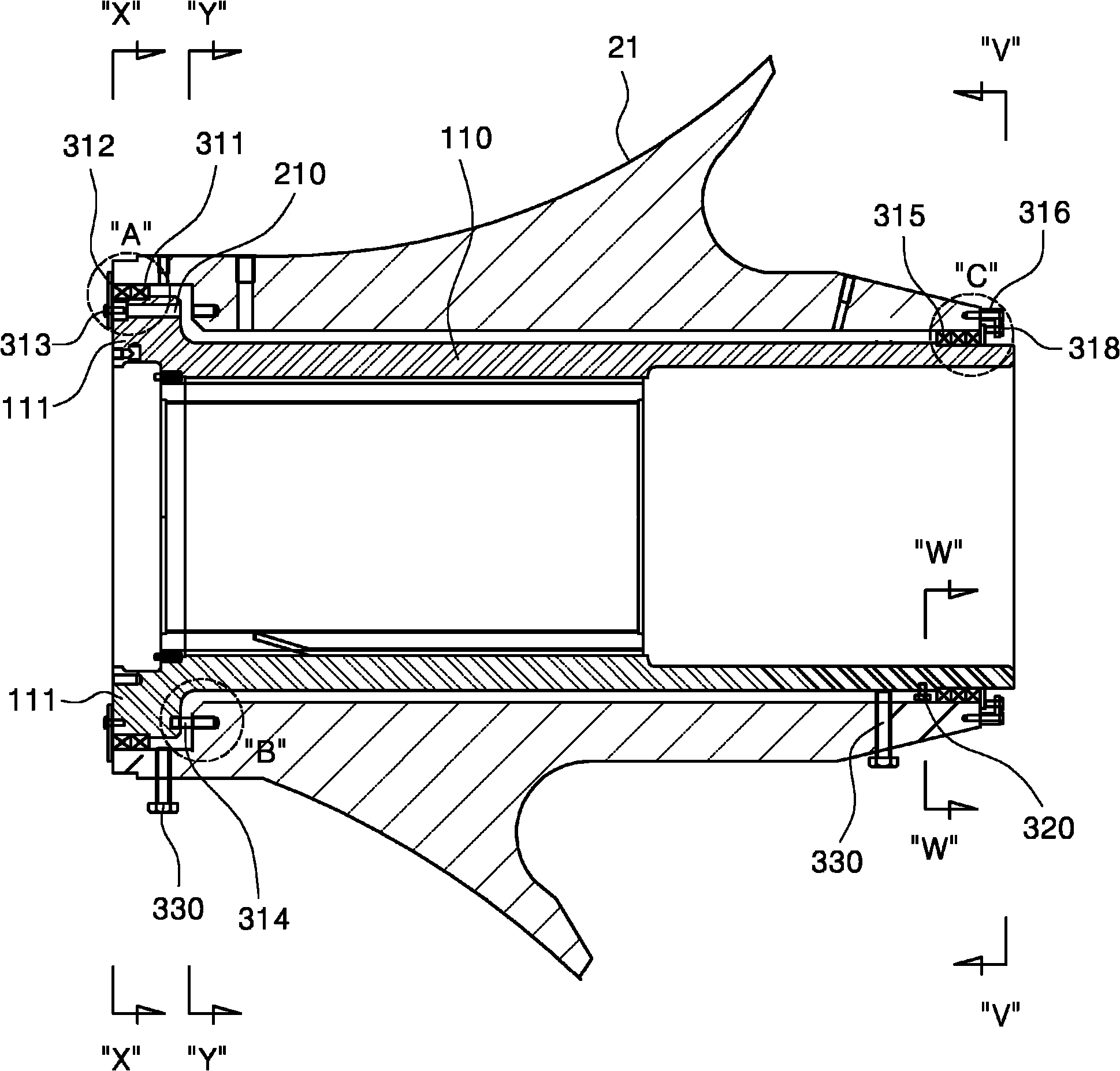

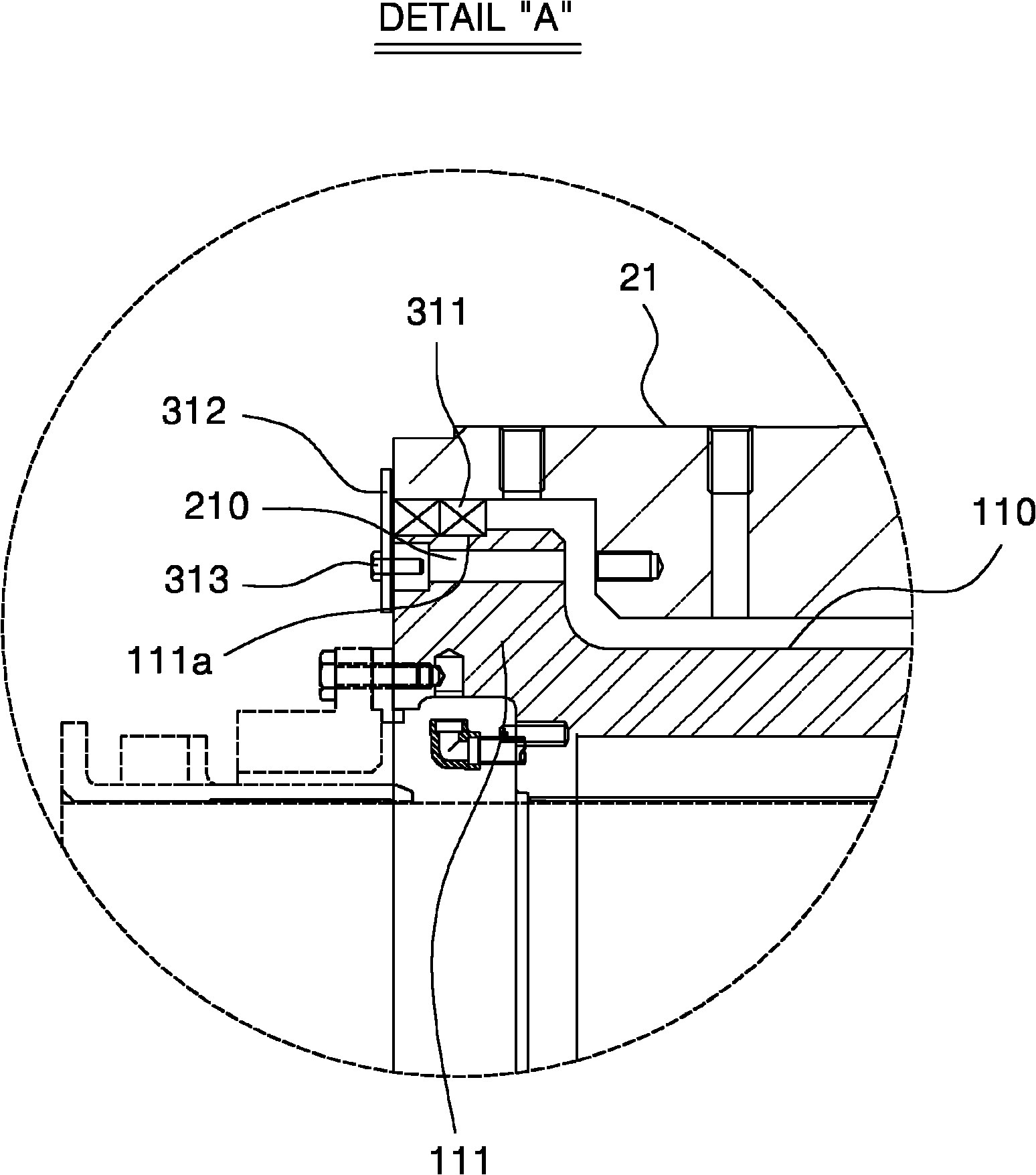

[0045] Next, a preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings.

[0046] figure 1 It is a sectional view of an important part of an embodiment of the stern tube bushing unit of the present invention; figure 2 for figure 1 A detailed schematic diagram of important parts of the structure on the stern side of the hull shown; image 3 for figure 2 Detailed schematic diagram of part "A" of ; Figure 4 for figure 2 A detailed schematic diagram along the X-X cross-sectional direction of ; Figure 5 for figure 2 Detailed schematic diagram of part "B" of ; Figure 6 to Figure 8 for figure 2 Detailed schematic diagrams along the Y-Y, Z-Z, W-W cross-sectional directions of each; Figure 9 for figure 2 Detailed schematic diagram of part "C" of ; Figure 10 for figure 2 A detailed schematic diagram along the direction of the "V" section; Figure 11 for Figure 9 An example of the setting state of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com