High-absorption process energy-saving device of pneumatic diaphragm pump

A technology of pneumatic diaphragm pump and energy-saving device, applied in the direction of pumps, machines/engines, pumps with flexible working elements, etc., can solve the problems of unusable, unreachable diaphragm pumps, liquid lifting, etc., to improve efficiency, save energy, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below according to accompanying drawing and specific embodiment:

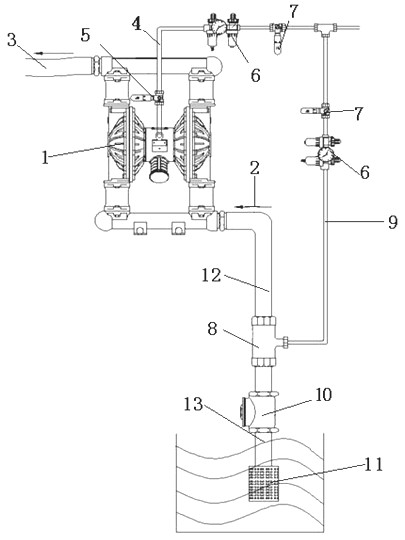

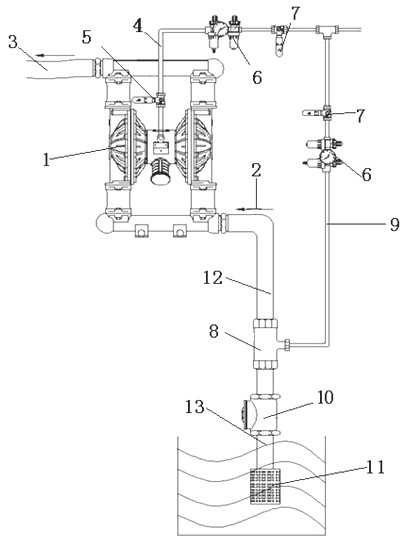

[0013] Such as figure 1 As shown, a pneumatic diaphragm pump high-suction energy-saving device includes a diaphragm pump 1, which is provided with an inlet 2, an outlet 3, and is connected with an air inlet pipe 4, and the air inlet pipe 4 is connected with an air source input pipe And pass through a manual ball valve 7, air filter pressure regulating valve 6 and leakage ball valve 5 successively and connect with the air inlet of this diaphragm pump 1, connect a first pipeline 12 at inlet 2, the other of this first pipeline 12 An opening is vertically downward and connected to the first end of a tee 8, the second end of the tee 8 communicates with the air source input pipeline through an air pipe 9, and the air pipe 9 is provided with a manual ball valve 7 and an air The third end of the filter pressure regulating valve 6 and the tee 8 is connected to a ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com