Resilient disc type coupling

A coupling and elastic disc technology, applied in elastic couplings, couplings, mechanical equipment, etc., can solve the relative displacement of the two shafts, the fixed rigid coupling has no compensation ability, etc. Good synchronization, safe and stable torque transmission, and the effect of preventing bolt loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

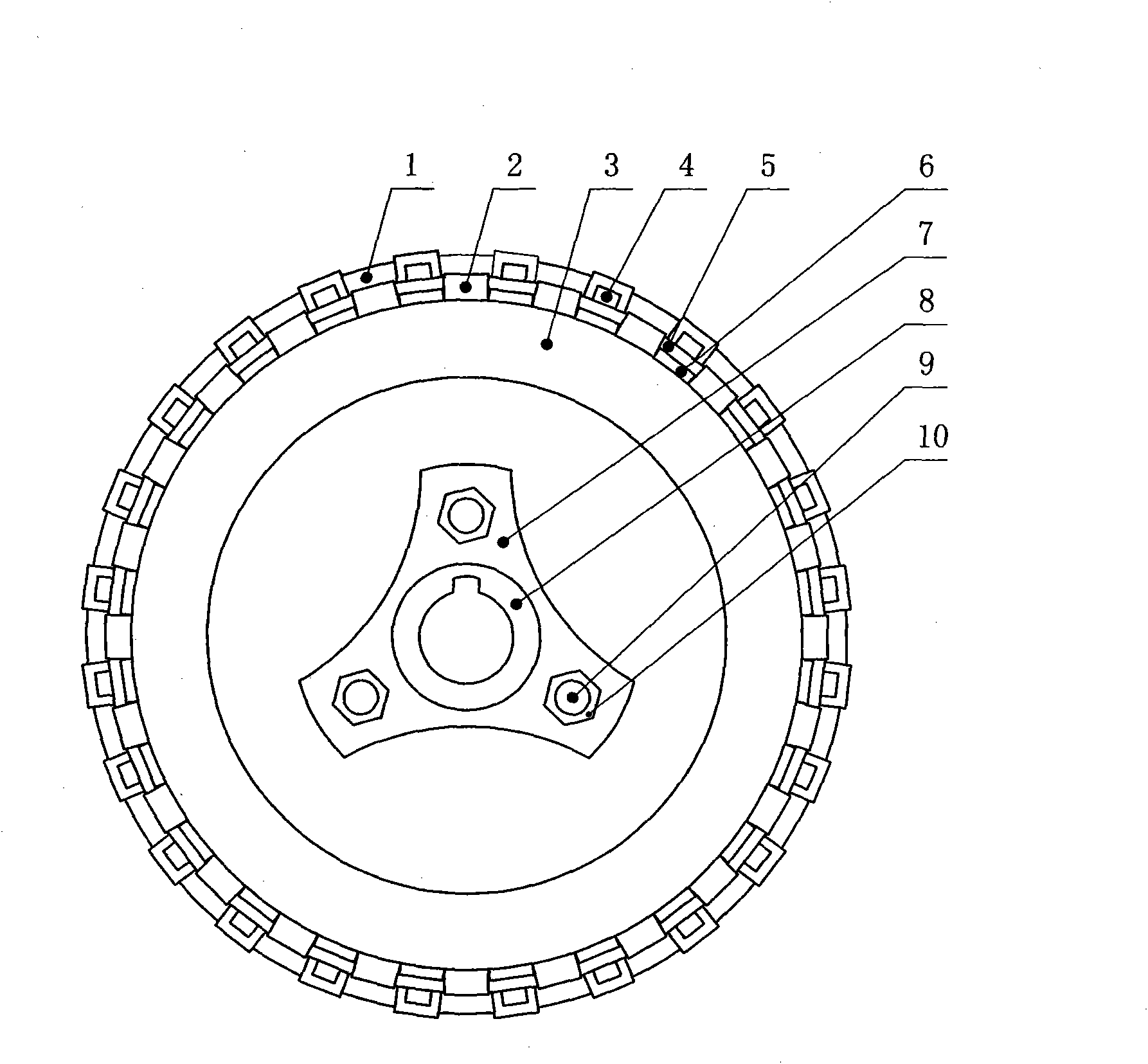

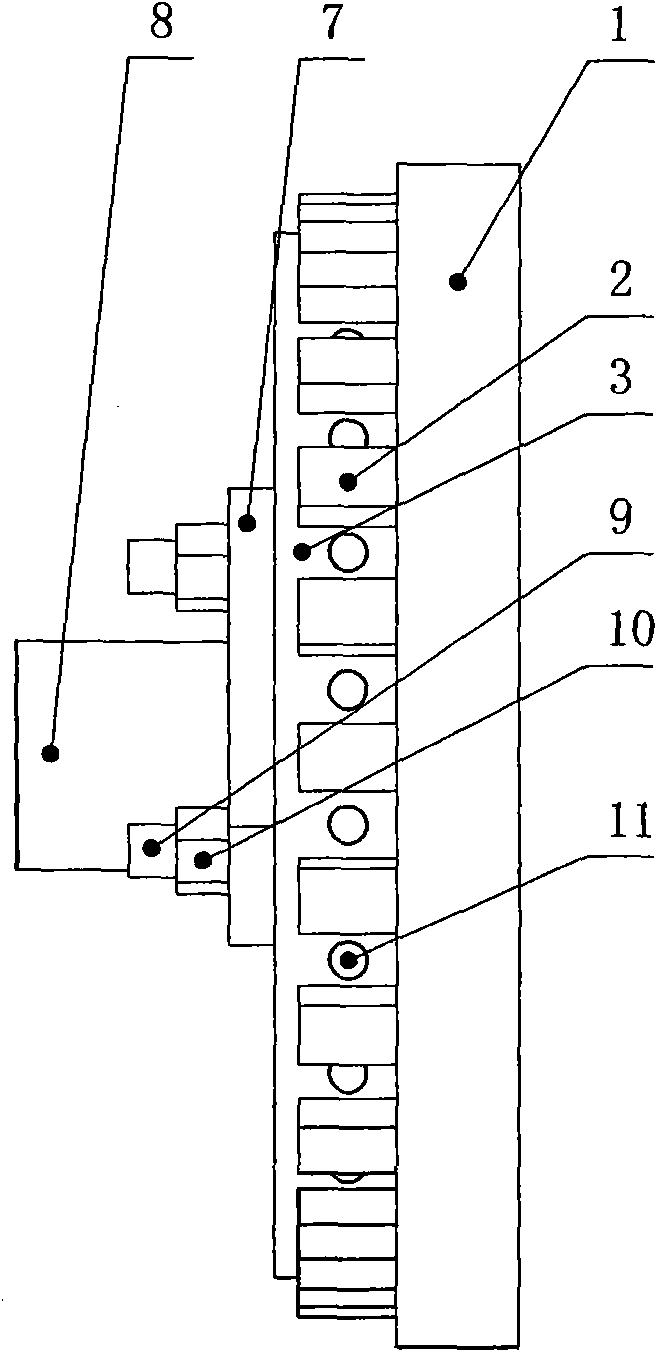

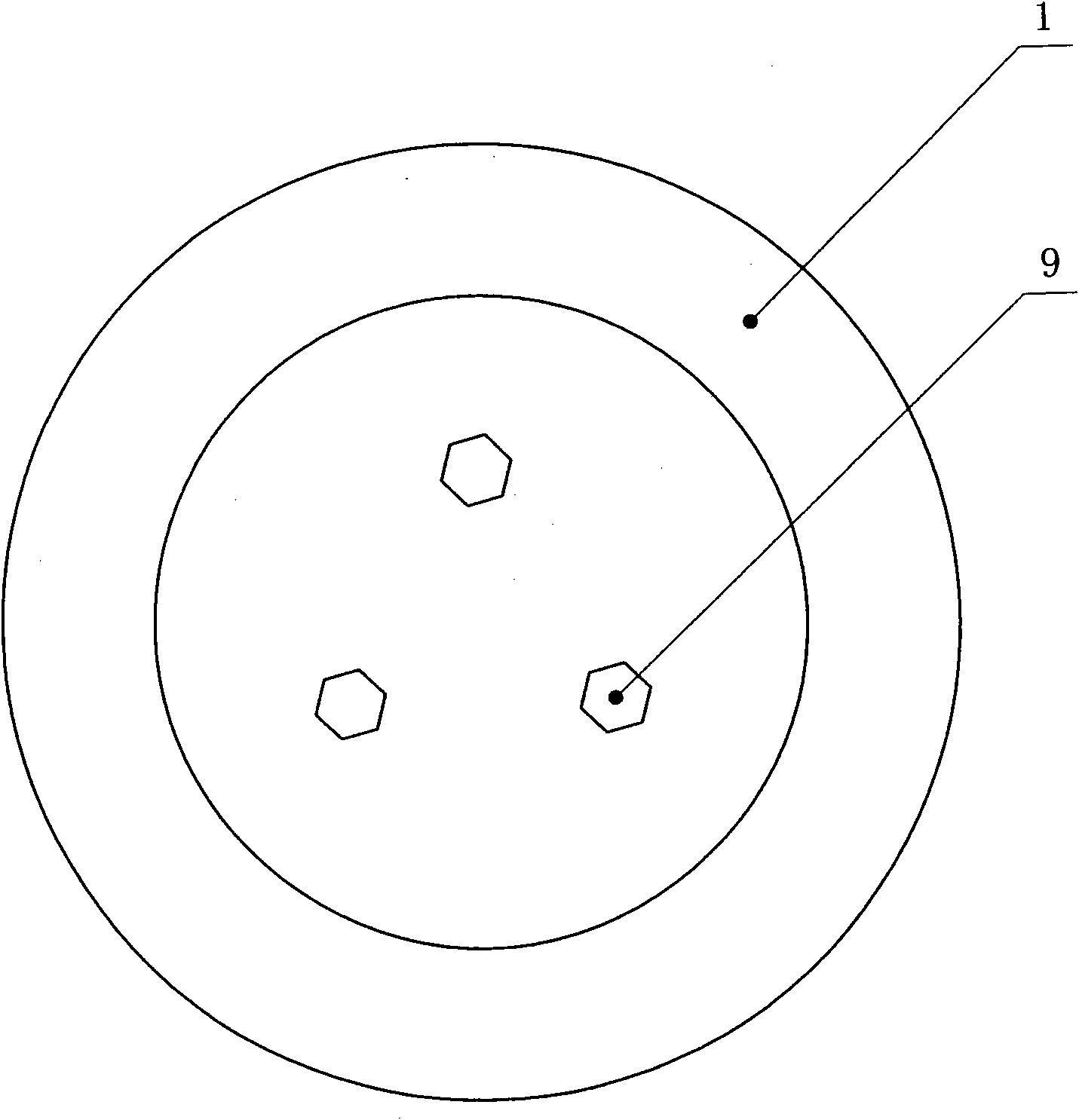

[0019] An elastic disc coupling, such as Figure 1~6 As shown, including the driving shaft connector and the driven shaft connector, the innovation of the present invention is that the structure of the driving shaft connector and the driven shaft connector is the same, and its structure is as follows figure 2 As shown (the view of the driven shaft connector is omitted): both are composed of a shaft sleeve 8 and a connection plate 3, and the shaft sleeve is coaxially fixed on the outer end surface of the connection plate. The specific connection relationship is: the end of the shaft sleeve is fixed The chuck 7 is fixed on the outer end surface of the connection plate through the locking bolt 9 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com