Winter anti-freezing ceiling fresh air unit system and construction method

A technology of fresh air unit and construction method, which is applied in air-conditioning systems, heating methods, space heating and ventilation, etc., can solve the problems of increased operation and management costs for equipment maintenance users, and achieves the saving of electric energy, operating costs and investment costs, and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

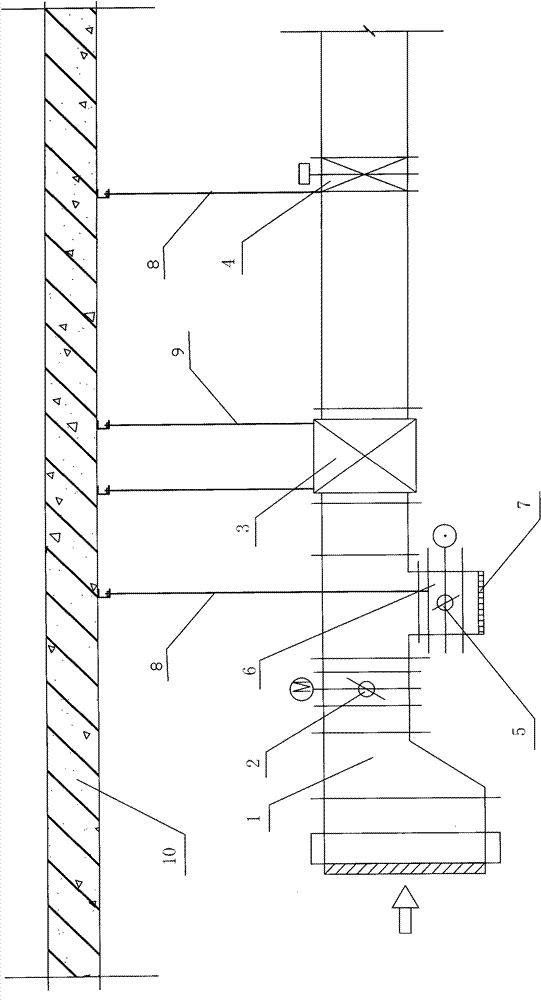

[0021] Embodiment 1: A suspended ceiling fresh air unit system for anti-freezing in winter includes: fresh air unit 3, electric airtight valve 2, fire damper 4, air duct 1 of the fresh air unit system, system support and hanger 8 and fresh air unit support and hanger 9, wherein One end of the system support and hanger 8 is fixed on the top plate 10, and the other end is fixed on the air duct 1 of the fresh air unit system. In the air duct 1 of the fresh air unit system, an electric airtight valve 2, a fresh air unit 3 and Fire damper 4, one end of fresh air unit support and hanger 9 is fixed on the top plate 10, and the other end is fixed on fresh air unit 3, which also includes manual airtight valve 5, single-layer louver 7 and iron short pipe 6, and electric airtight valve 2 On the air duct 1 of the fresh air unit system between the fresh air unit 3 and the fresh air unit 3, a bypass port is set on the side close to the indoor. The opening size of the bypass port is 600mm×600...

Embodiment 2

[0022] Embodiment 2: A construction method of a suspended ceiling fresh air unit system for anti-freezing in winter, which is implemented in the following steps:

[0023] (1) Measurement and setting out: measure and set out to determine the axis of the air duct 1 of the fresh air unit system and the positions of the centerlines of each surface of the fresh air unit 3, electric airtight valve 2 and fire damper 4;

[0024] (2) Install the system support and hanger: install the system support and hanger 8 according to the hoisting size of the equipment, fix one end of the system support and hanger 8 on the top plate 10, and the other end extends vertically downwards to fix the fan of the fresh air unit system. pipe 1;

[0025] (3) Install the fresh air unit: fix one end of the fresh air unit hanger 9 on the top plate 10, and extend the other end vertically downwards to connect with the fresh air unit 3 to fix the fresh air unit 3;

[0026] (4) Install the air duct of the fresh a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com