Double-acting life test bed for shock absorber

A technology of life test and shock absorber, which is applied in the direction of vehicle suspension/shock absorbing mechanism test, etc. It can solve the problems of long test period, inability to actually imitate the car, and difficult observation and test of the actual situation, and achieve the effect of clear control interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

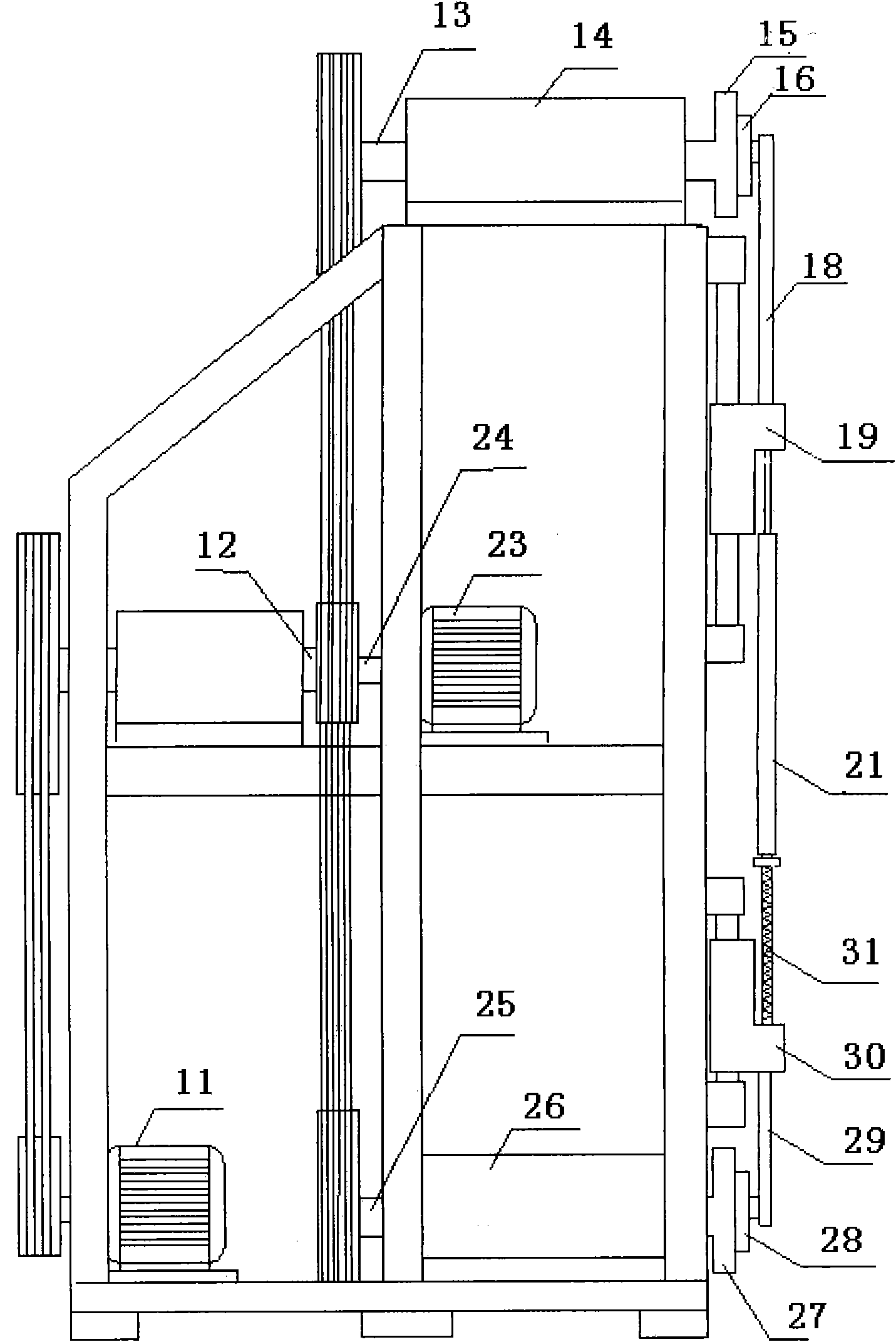

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

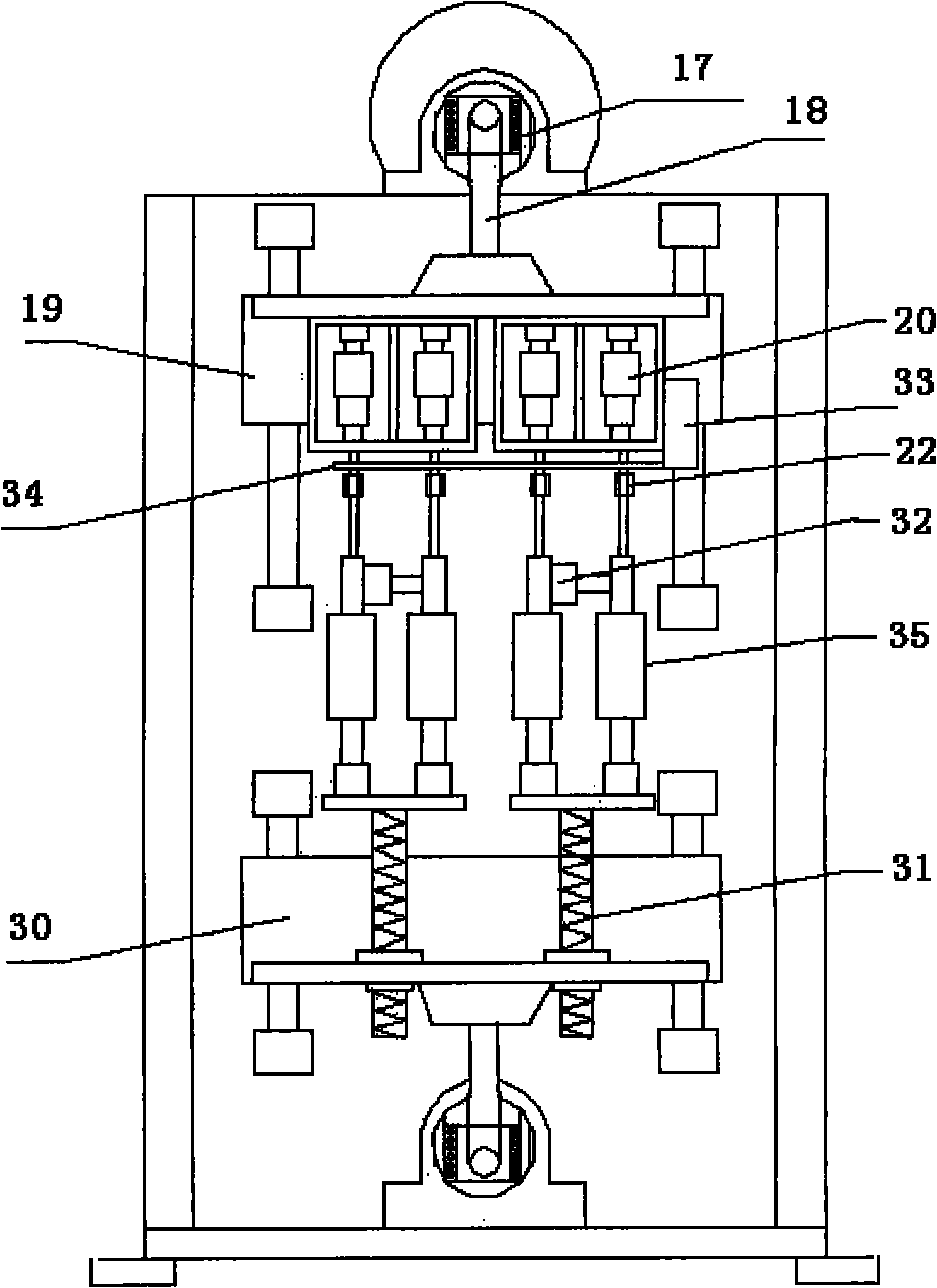

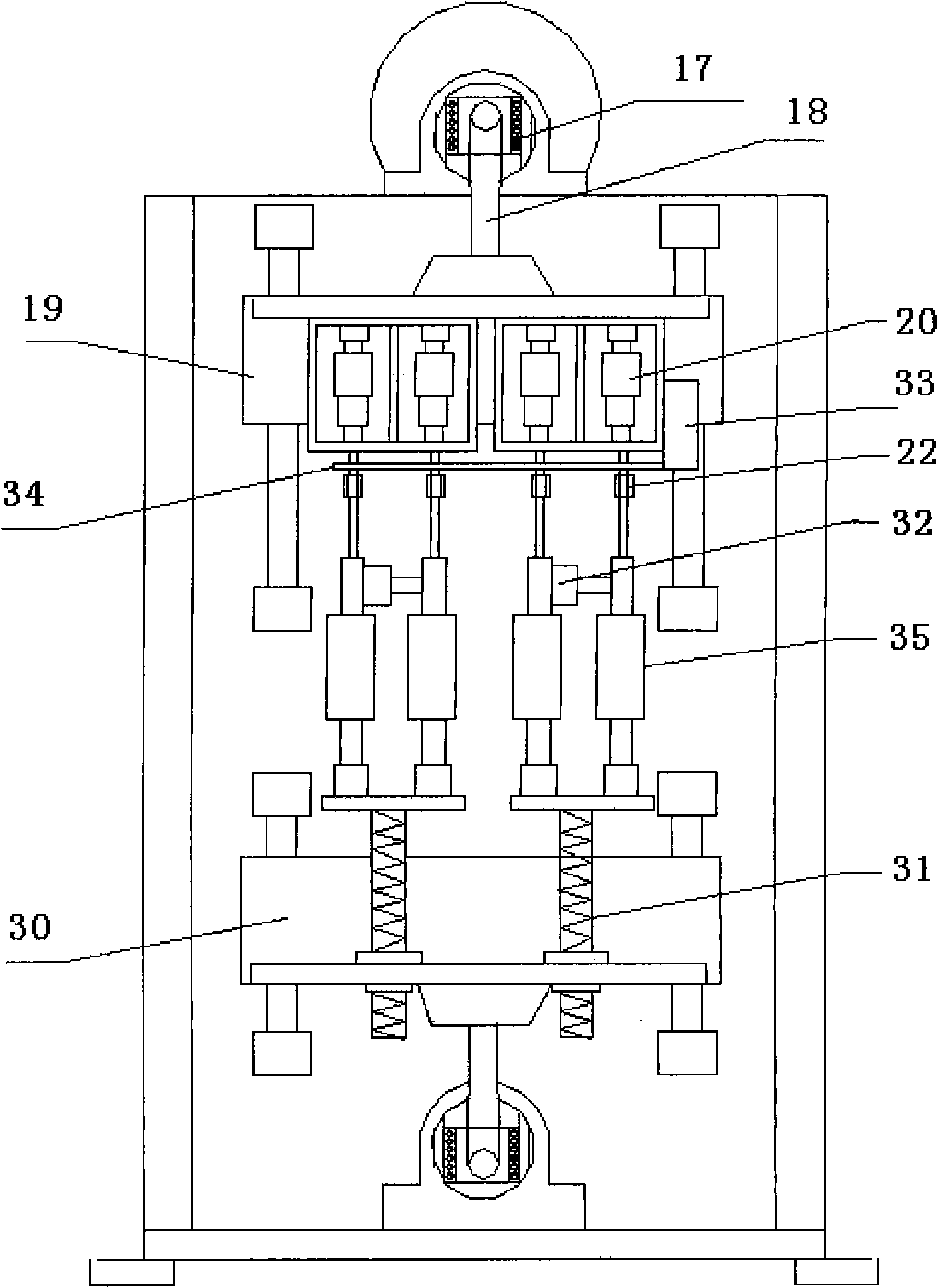

[0015] The invention simulates ground vibration and vehicle body vibration at the same time, respectively sets upper and lower vibration-exciting mechanisms, a lateral force mechanism and a reciprocating swing mechanism on the main body, and conducts an intensive life test on the measured shock absorber.

[0016] like figure 1 , figure 2 As shown, the upper excitation motion is a low-frequency large-amplitude motion, simulating the vibration of the body part; the lower excitation motion is a high-frequency small-amplitude motion, simulating the ground vibration induced by the wheel. Both the upper and lower exciters are driven by a crank-link mechanism. The above exciter is an example, it includes a motor 11 arranged below the main body, the motor drives an intermediate shaft 12, the intermediate shaft 12 drives the crankshaft 13 through conversion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com