Lens fixing device and optical pickup device

A lens fixing and lens technology, which is applied in the beam guiding device, optics, installation and other directions, can solve the problems of optical axis offset, complex and complicated structure of the lens holder 30, and achieves a simple structure, suppresses optical axis offset, and is easy to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

change example

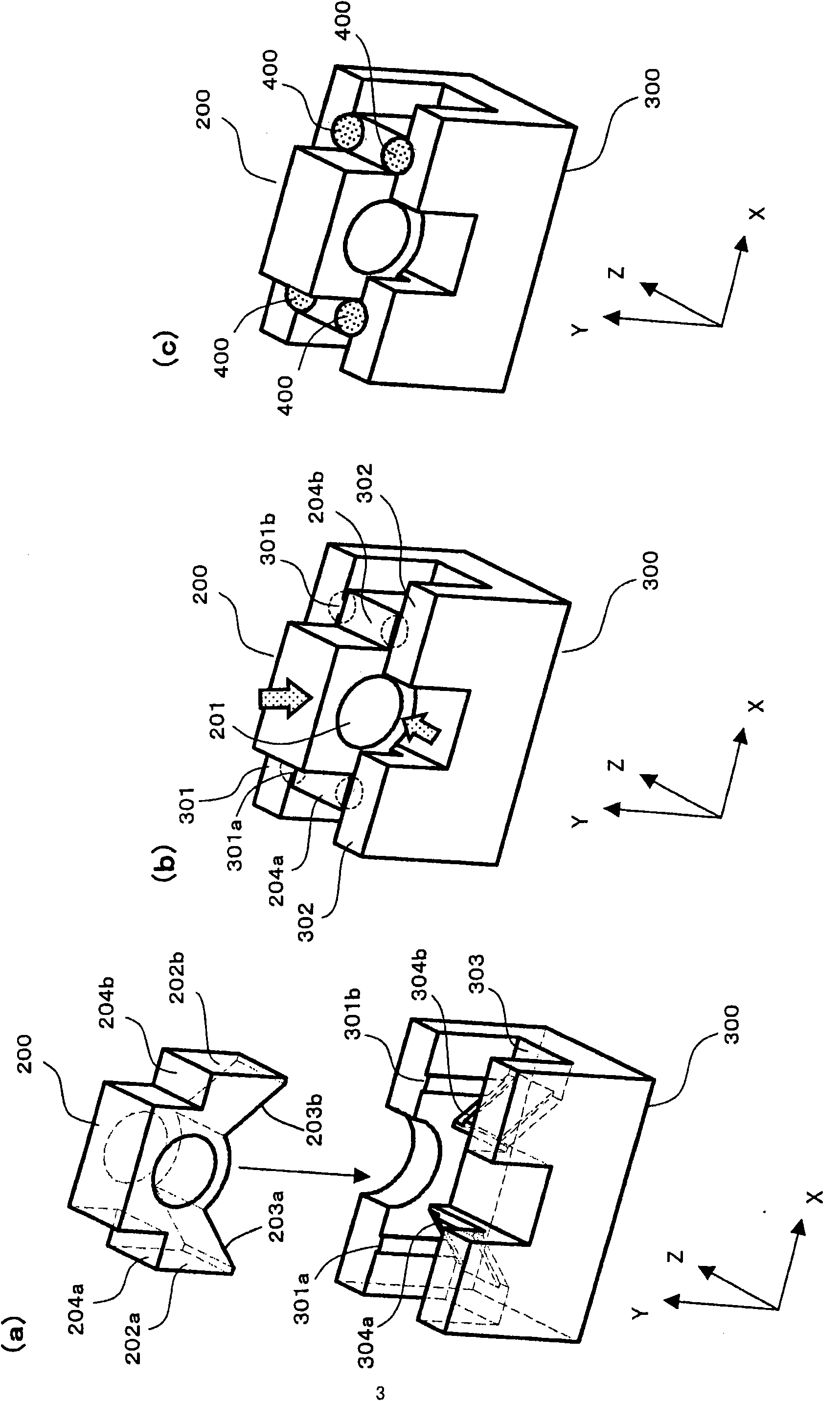

[0068] Figure 5It is a figure which shows the modification example of a lens fixing device. In this modified example, two tapered protrusions 210a, 210b are formed on the front surface of the lens holder 200 as shown in FIG. The protrusions 210 a and 210 b are arranged at positions substantially aligned with the protrusions 301 a and 301 b in the Z-axis direction when the lens holder 200 is mounted on the mounting portion 300 . In addition, the height D1 of the protrusions 210a, 210b, as shown in the partially enlarged view of FIG. Compared with the gap D2, the amount of D3 is large.

[0069] In this modified example, the positioning of the lens portion 210 in the optical axis direction can be easily performed by the function of the protrusion 210a. i.e., as above image 3 When the lens holder 200 is inserted into the concave portion 303 , the protrusions 210 a and 210 b hit the back surface of the wall portion 302 , and the lens holder 200 receives a force in the directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com