Telescopically collapsible scissor car jack

A lift and scissor technology, applied in the field of lifts, can solve the problems that hinder the reliable function of the lift, and achieve the effect of simple hand operation and small storage volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

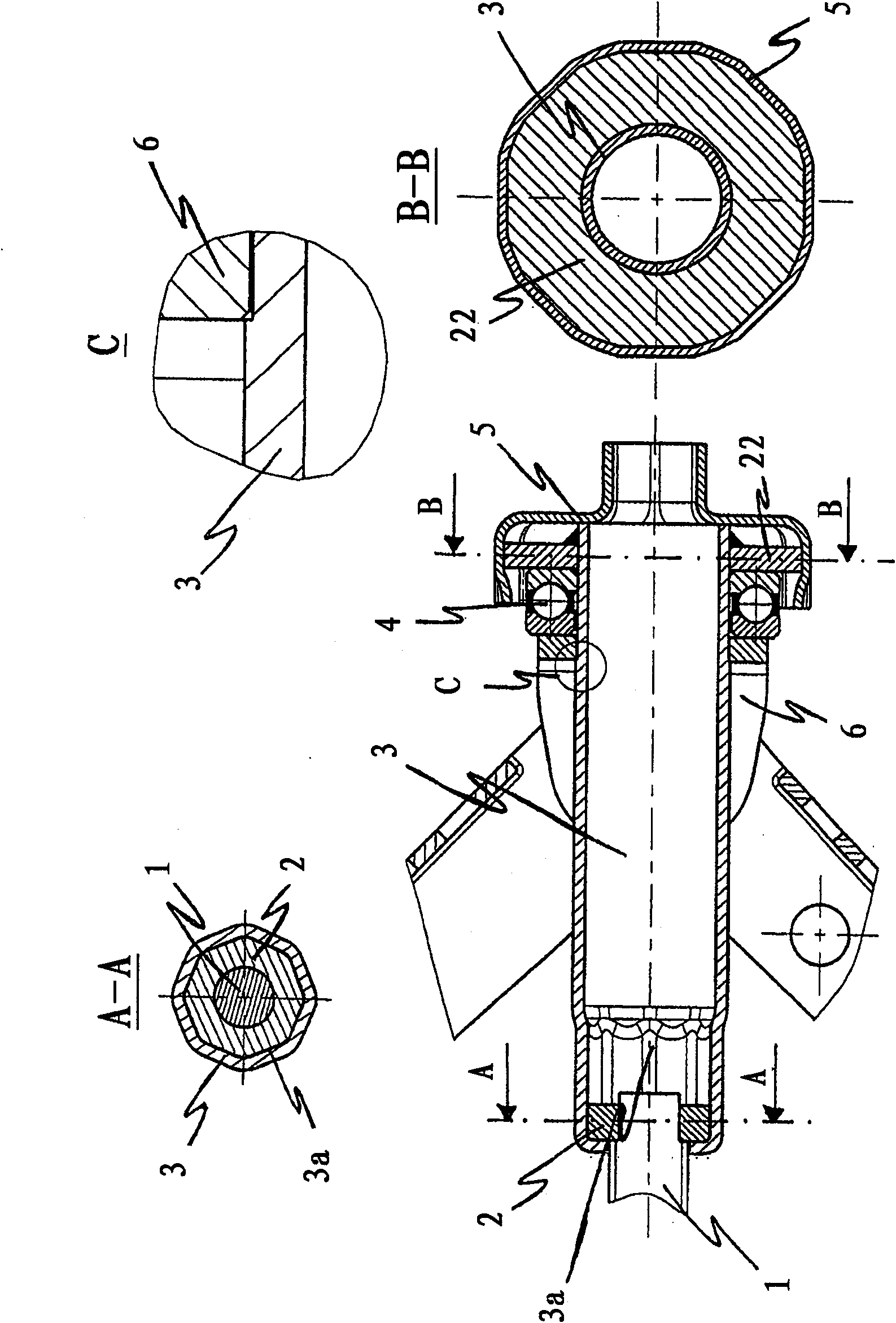

[0099] The spindle 1 is threaded and turned slightly at one end so that the spindle driver 2 can be pressed or welded in. On the other end, the mandrel 1 is partially extruded into 1a. The spindle driver 2 is a disk with a hole in the middle, which corresponds to the twisted part of the spindle. The outer circumference of the spindle driver 2 is polygonal (for example hexagonal) and is configured according to the inner polygon of the guide tube 3 .

[0100] The guide tube 3 is a thin-walled polygonal tube (for example a hexagonal tube) having a hole 3d with an inward radial wall 3a on one side and an outward radial wall 3b on the other side. The hole 3d is slightly larger than the diameter of the mandrel 1 . The spindle driver 2 is supported on the inner radial wall 3 a, wherein the spindle 1 can be moved axially within the guide tube 3 by means of the spindle driver 2 . By means of a polygonal allen wrench (eg a hexagonal allen wrench) positioned on the other side of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com