Dual-mode printer

A printer, dual-mode technology, used in printing and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

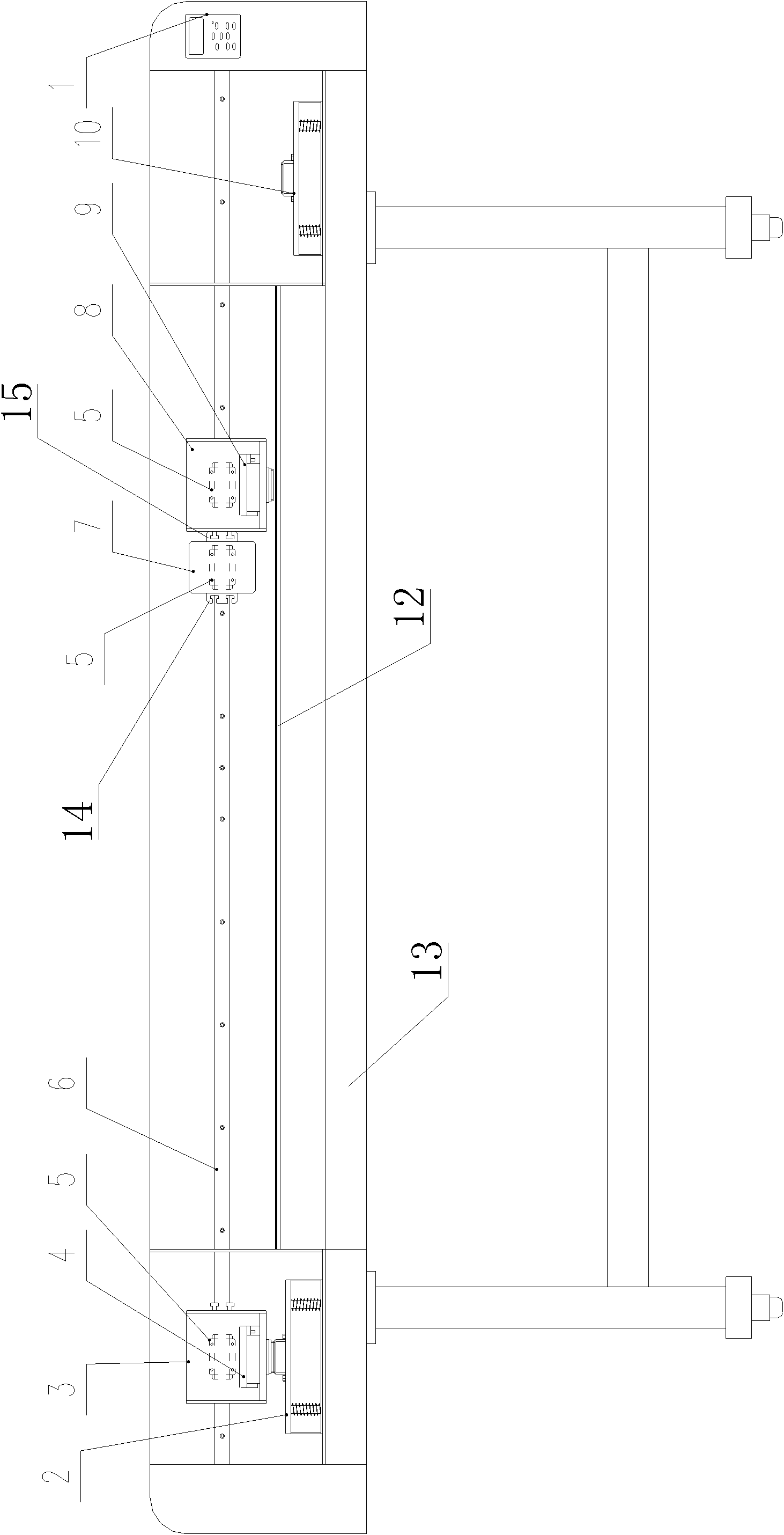

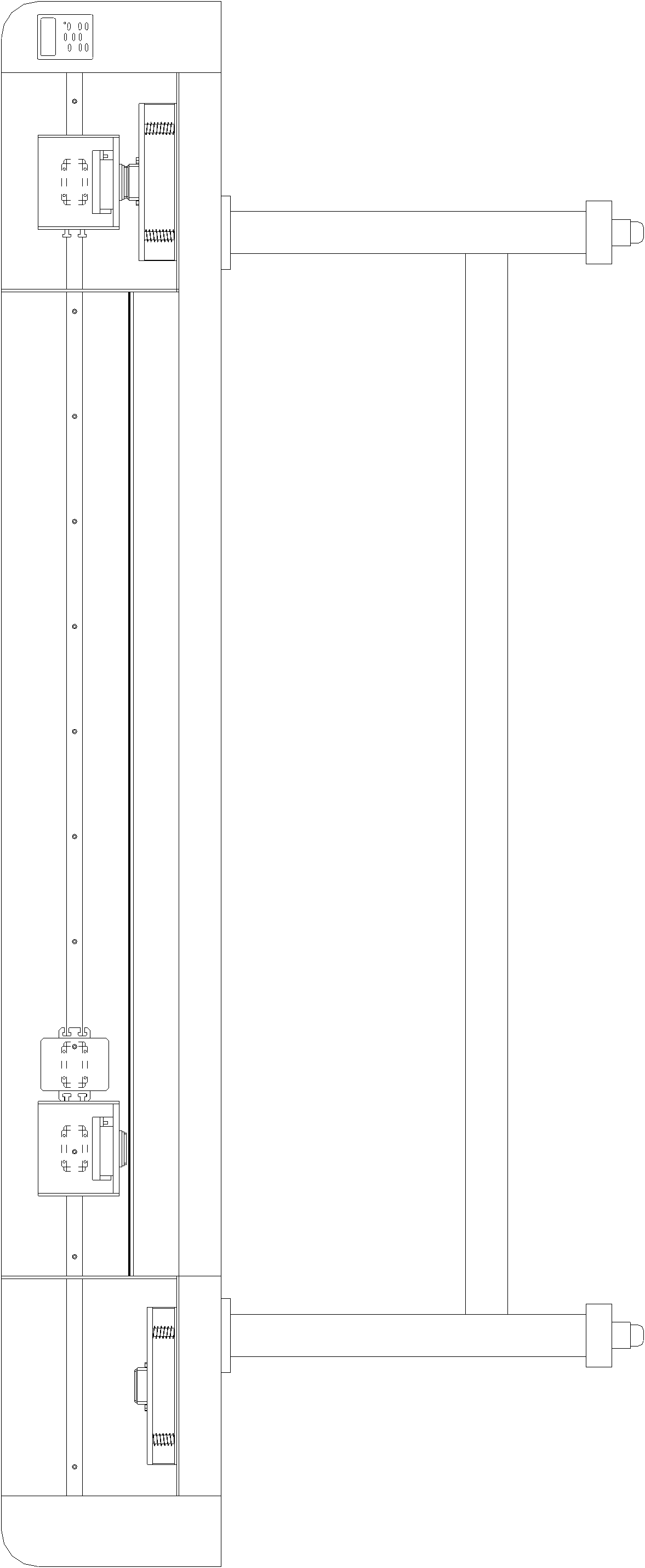

[0014] see figure 1 , 2 The shown printer includes a body 13 and a guide rail 6 arranged on the body, on which a first printing cart 8, a second printing cart 3 and a print head driving connection device 7 are slidably arranged. The first printing carriage 8 , the second printing carriage 3 and the print head drive connecting device 7 are all slidably connected to the guide rail through the slider 5 . The first printing head 9 and the second printing head 4 are respectively fixed on the lower parts of the first printing carriage 8 and the second printing carriage 3 . The second printing cart 3, the print head driving connection device 7, and the first printing cart 8 are arranged in sequence from left to right along the guide rail.

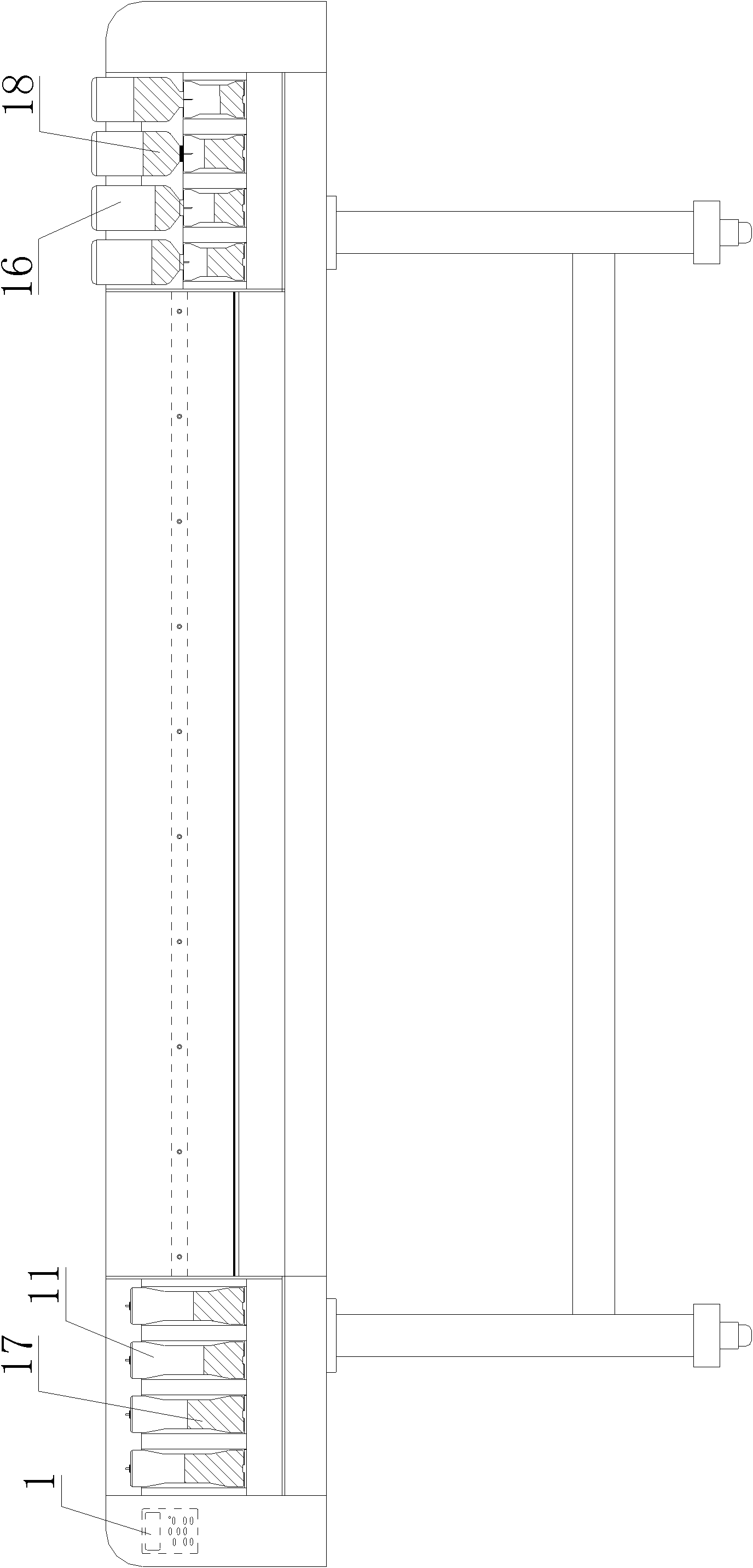

[0015] A first ink supply device 11 for supplying ink to the first printing head 9 is provided at the rear of the machine body at the right end of the guide rail, and water-based inks 17 of four different colors are housed in the first ink suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com