Single beam girder erecting machine

A bridge erecting machine, single girder technology, used in bridges, bridge construction, erection/assembly of bridges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

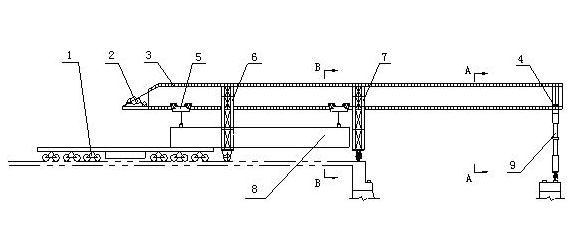

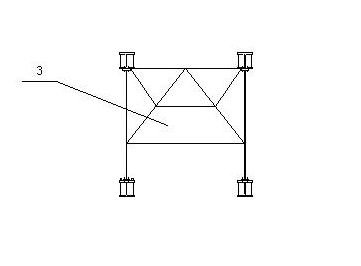

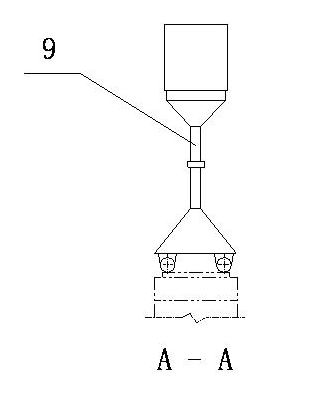

[0014] A single girder bridge erecting machine, comprising a main girder 3, a girder transporting vehicle 1, a trolley 5, a front outrigger 9, a middle outrigger 7, a rear outrigger 6 and a lifting mechanism 2, the main girder 1 is composed of four H-shaped steel and The steel plates are connected to form a single beam. The H-shaped steel at the lower end of the main beam 1 is provided with a square steel track. The trolley 5 is suspended on the square steel track on the H-shaped steel at the lower end of the main beam 1. The trolley frame passes through on both sides. Pin shafts 12 are connected to achieve three-point statically indeterminate balance. The trolley 5 enables the adjacent symmetrically suspended wheel treads to be self-adjustable on rail surfaces of different heights through the eccentric shaft 13, thereby ensuring that the wheel pressure is balanced. The front outrigger 9 is a single outrigger, which is composed of a hydraulic telescopic oil cylinder, a rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com