Field apparatus inspection method and system

A technology of field equipment and inspection system, applied in the direction of transmission system, digital transmission system, inspection time patrol, etc., can solve the problems of inability to comprehensively manage the enterprise, poor real-time performance, and simple verification of data authenticity in a timely manner, so as to achieve improvement The effect of inspection management level, reduction of safety accidents, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

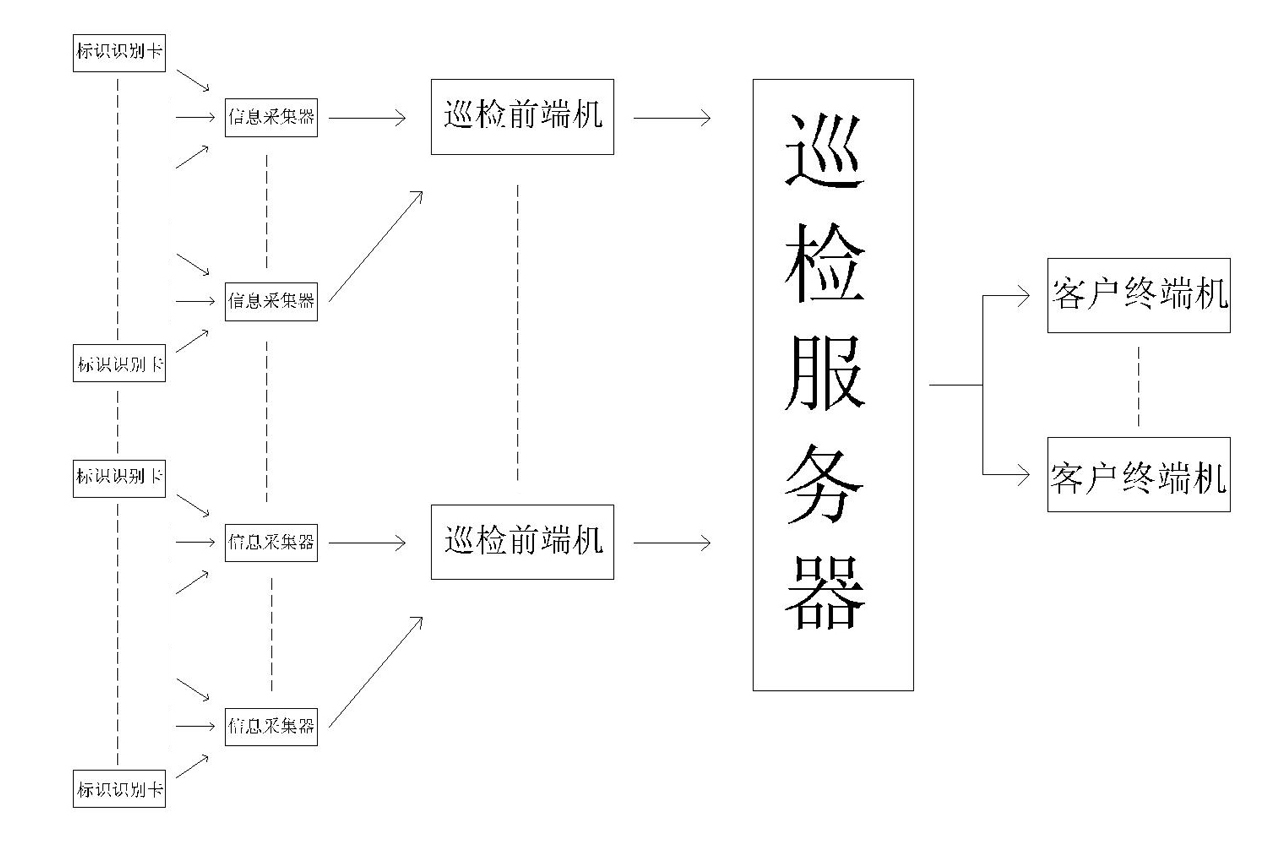

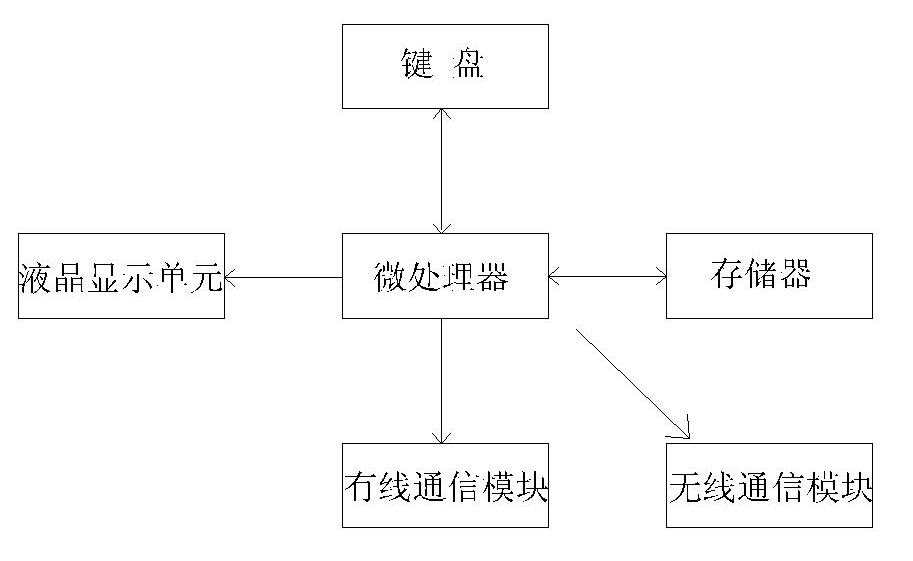

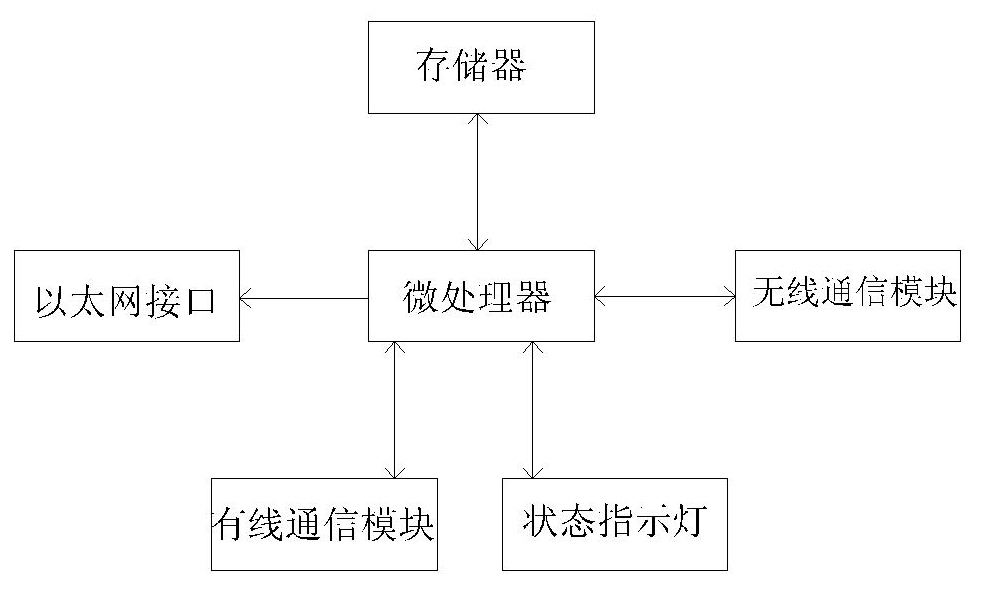

[0011] As shown in the figure, the field device inspection system includes an identification card and an information collector for swiping the card. The information collector is composed of a microprocessor, a keyboard, a memory, a liquid crystal display unit, a wireless communication module, and a wired communication. Module composition; the inspection front-end machine used to receive the data collected by the information collector, the inspection front-end machine is composed of a microprocessor, an Ethernet interface, a memory, a status indicator, a wireless communication module and a wired communication module; The patrol server connected with the patrol front-end machine to analyze and judge patrol information and generate statistical reports, and the terminal connected with the patrol server through the Ethernet to obtain statistical reports.

[0012] The method for patrol inspection of the field equipment is as follows: an identification card with a built-in identification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com