Engagement arrangement

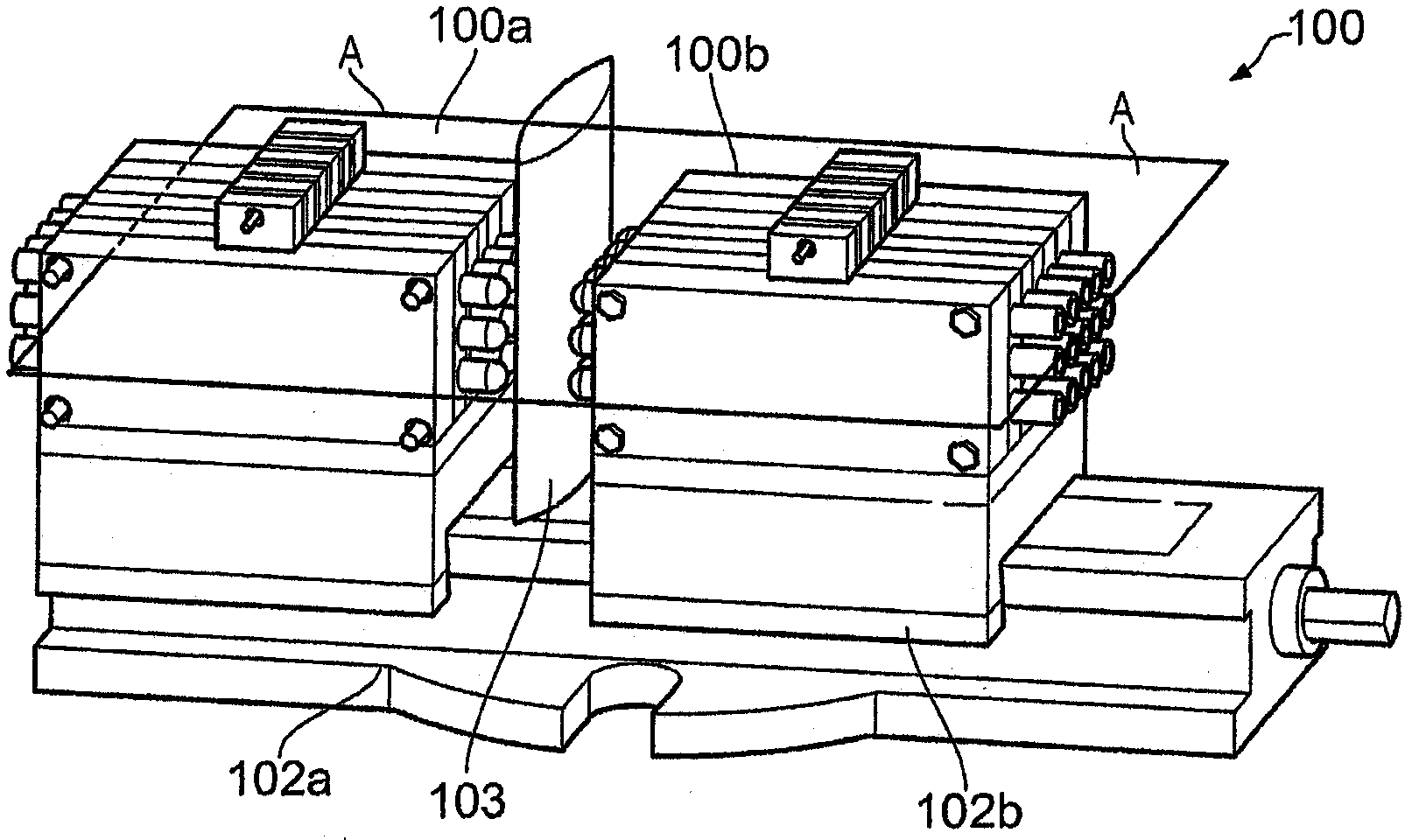

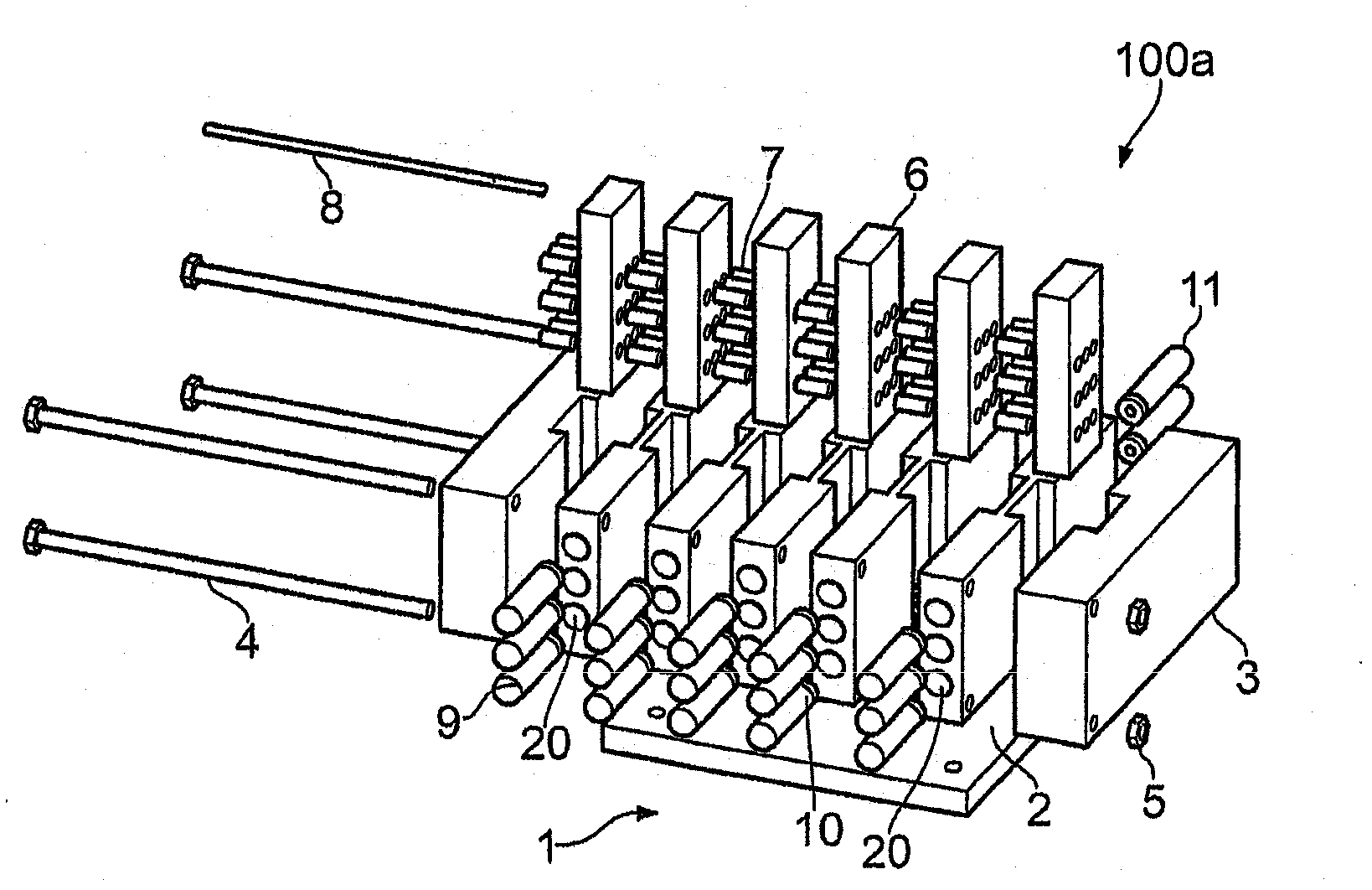

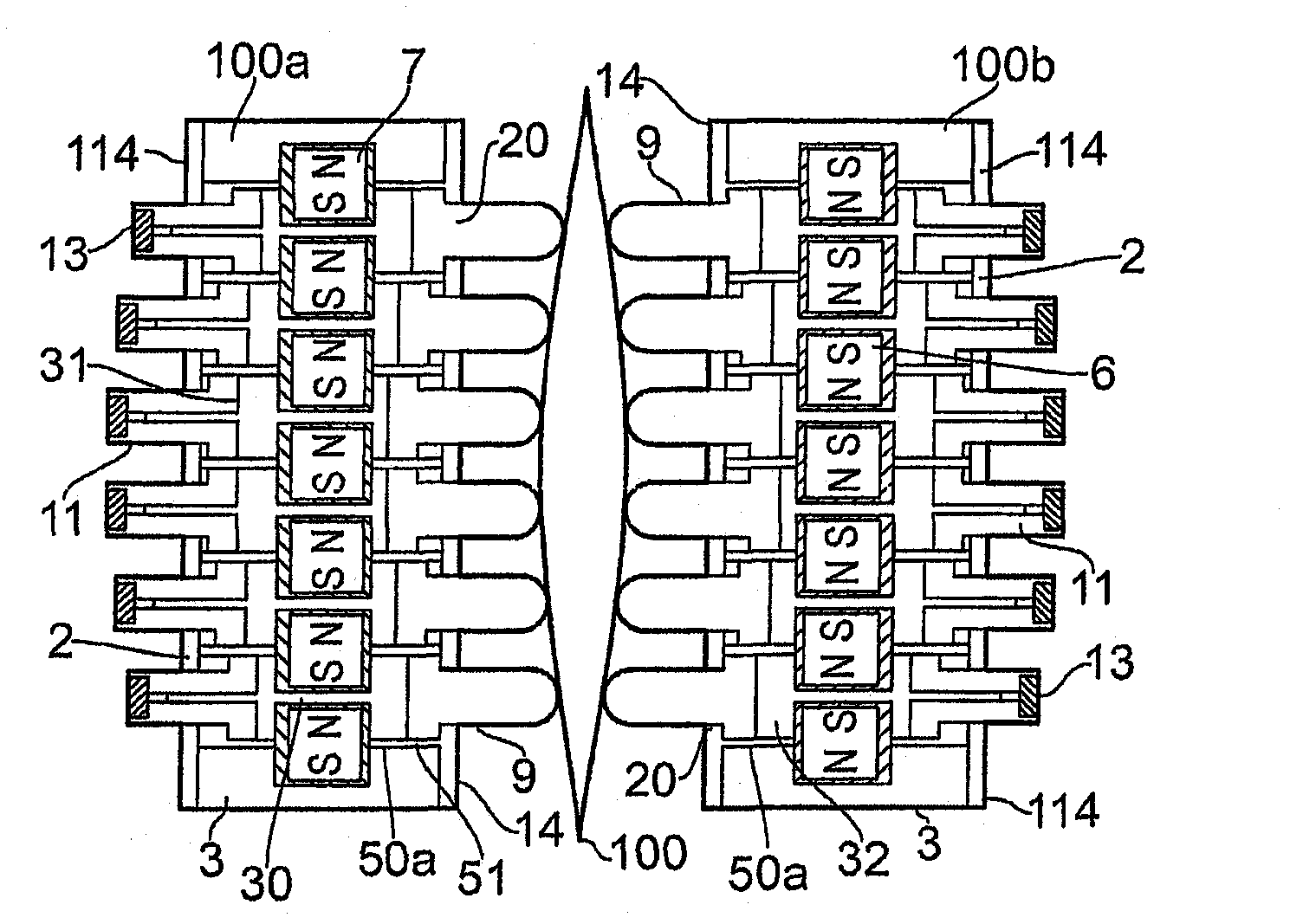

A technology for jointing devices and jointing components, which is applied in the direction of workpiece clamping devices, vises, manufacturing tools, etc., and can solve the problems of reduced effectiveness of MR fluid control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] As noted above, reconfigurable properties are required to provide engagement means that allow the retention and gripping of members and assume a variety of regular or irregular shapes. According to aspects of the invention, the reconfigurable properties are achieved by using known magnetorheological fluids and referred to as MR fluids. Such MR fluids are well known for their properties and generally comprise a suspension of magnetically inducible particles which, under the influence of a magnetic field, acquire a near-solid viscosity in use. In this case, the fluid can transition between a fluid state and a substantially solid state. This capability is useful in a variety of contexts and, for aspects of the present invention, allows the fluid state of a device to be adjusted for engagement to a component and then maintained in that engaged position by converting the MR fluid or part of the fluid to a solid state. It will be appreciated that once initial contact and ret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com