Continuous mixing-kneading extruding machine

An extruder and kneading technology, which is applied in the field of continuous kneading extruders, can solve the problems of inability to achieve large-volume operations, high mixing accuracy, and low mixing accuracy, and achieves simple and novel structure, enhanced kneading function, and simple and convenient maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is further described in conjunction with accompanying drawing and embodiment:

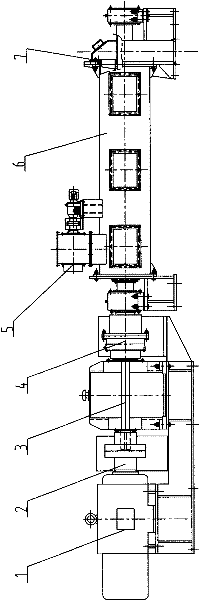

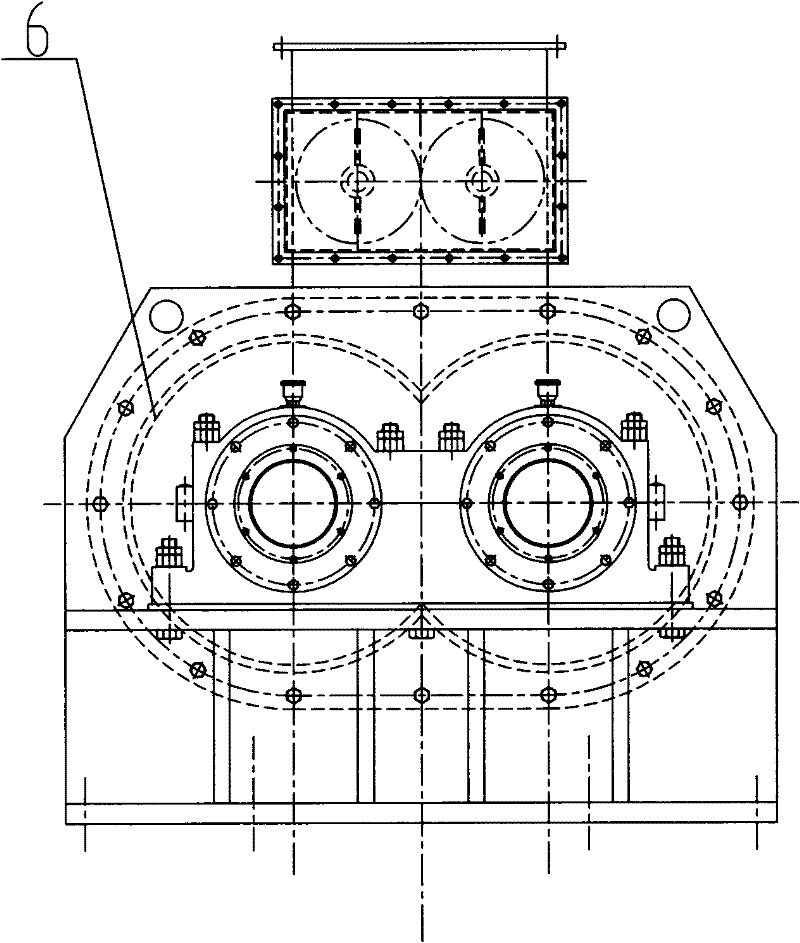

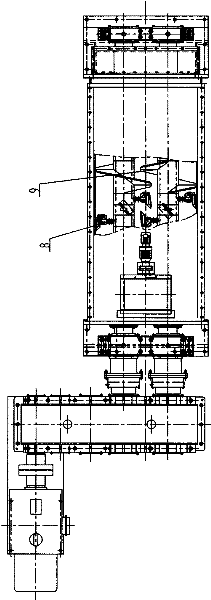

[0041] Such as figure 1 shown, combined with Figure 4 , Figure 5 , a continuous kneading extruder, including a forced feeding device, a main transmission mechanism, and a barrel frame 6; the forced feeding device is arranged above the feed port of the barrel frame, and the forced feeding device includes two transmission shafts , synchronous gearbox 10, housing 11, motor reducer 19, fixed plate 15 and bearing seat 16, one of the two transmission shafts is the active transmission shaft 12, and the other is the passive transmission shaft; both the active transmission shaft and the passive transmission shaft are There are active forced blades 13 and passive forced blades 14, both transmission shafts are fixed on the housing 11 through bearings 17 and bearing seats 16, the active transmission shaft is driven by the motor reducer 19 through the coupling 18 to drive the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com