Sleeve sealed inside diameter test gauge

A technology of inspection gauges and inner diameters, applied in the field of inspection gauges, can solve the problems of complex measurement operations and inability to meet the needs of on-site inspections, and achieve the effects of simple operation, excellent adjustable performance, and convenient inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

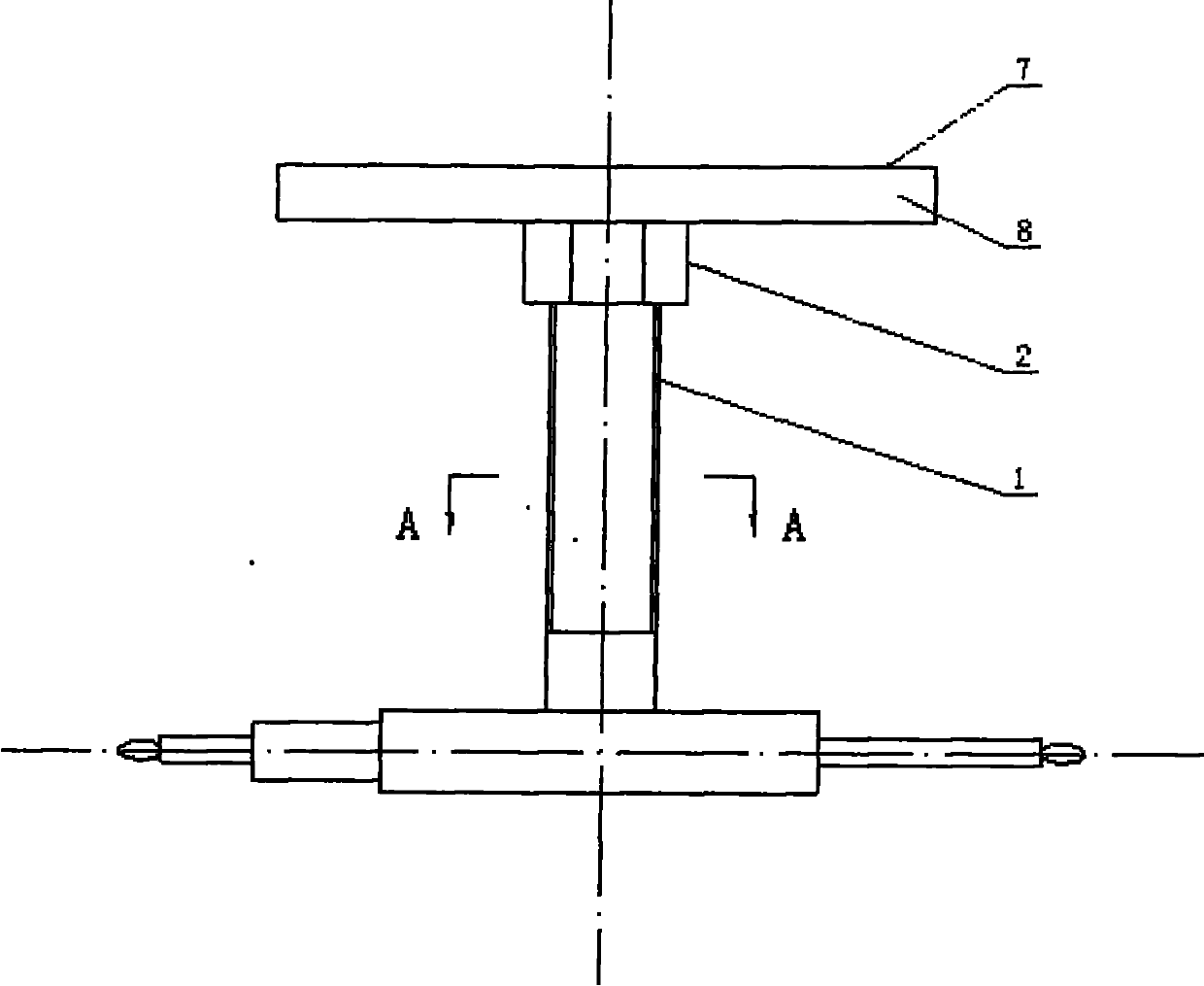

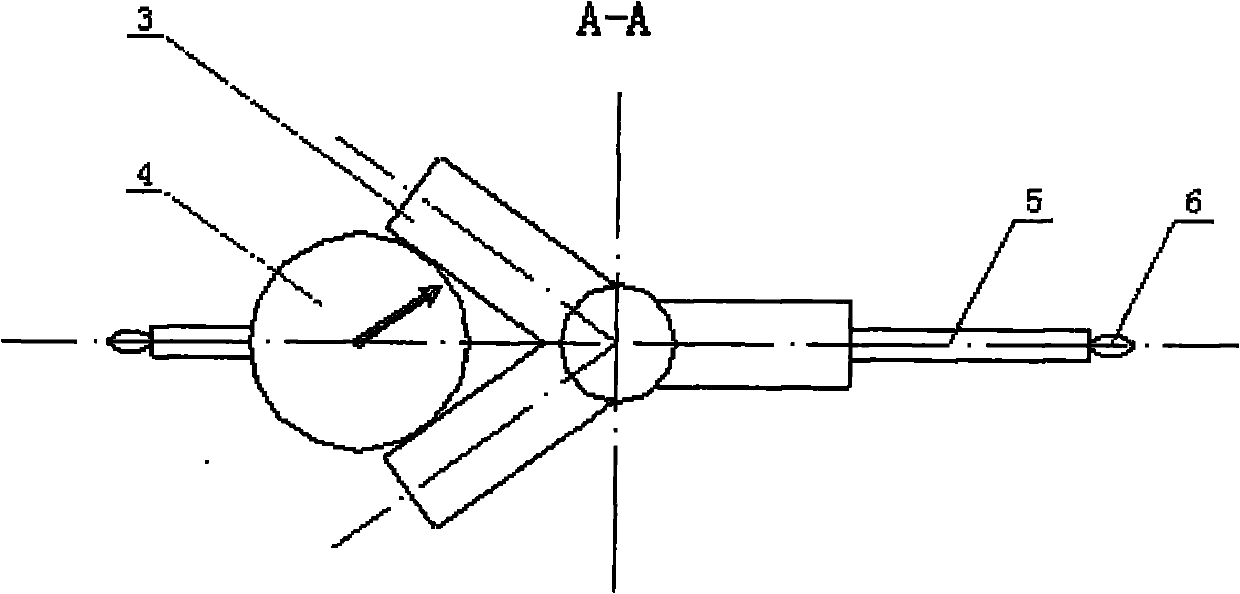

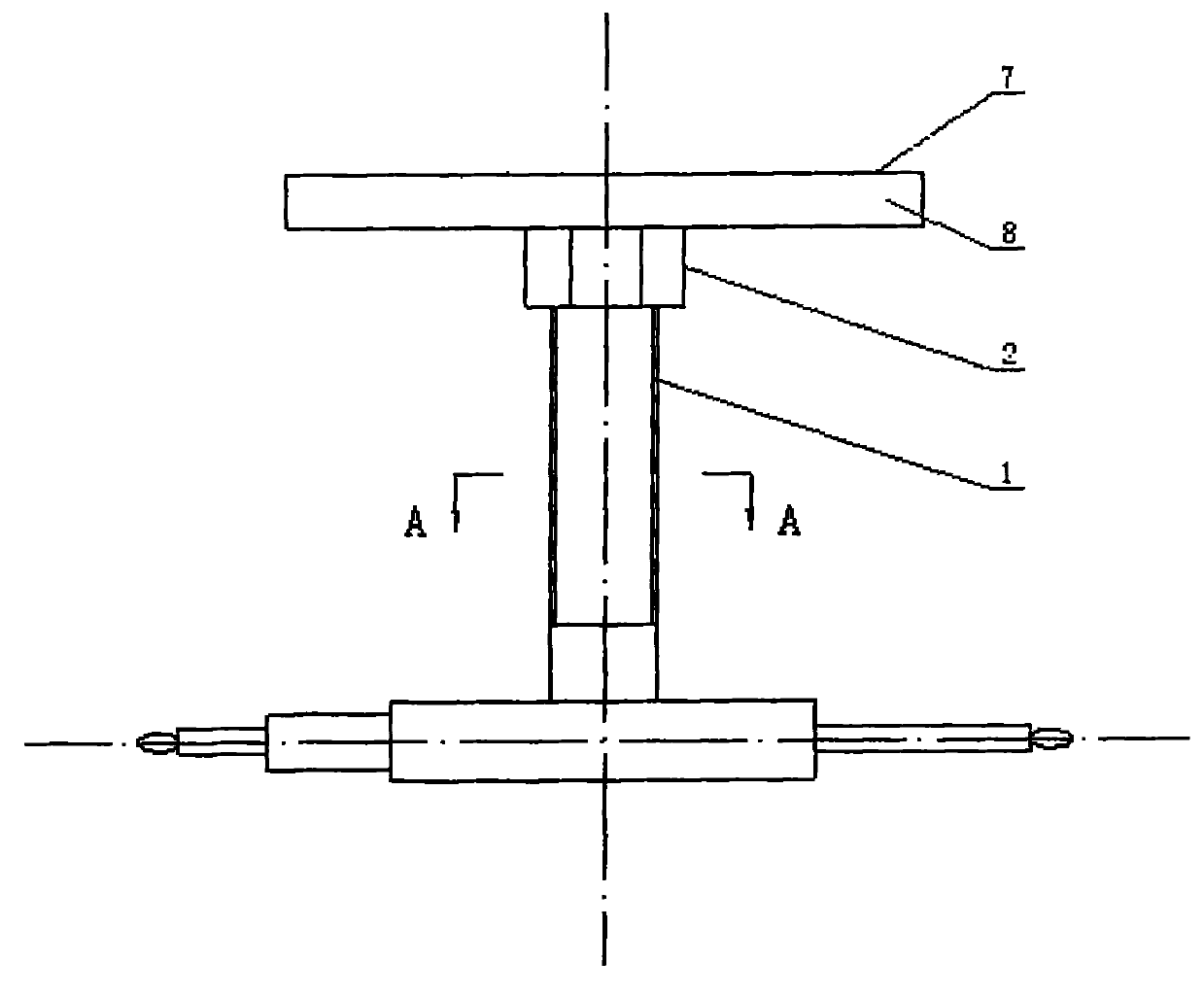

[0012] Combine below figure 1 , figure 2 The structure of the present invention is described in detail:

[0013] A casing seal inner diameter inspection gauge, mainly composed of a depth screw 1, a lock nut 2, a gauge device 3, an indicator dial 4, an extension rod 5, a contact point 6, a reference plate 7 and a wear plate 8, wherein the reference plate The backing plate 7 is placed above the wear-resistant plate 8, the wear-resistant plate 8 is connected with the depth screw 1 through the lock nut 2, and the meter device 3 is connected under the depth screw 1, and the indicator device 3 is respectively connected with the indicator dial 4 and the connecting rod. 5 are connected, and a contact 6 is provided at the rod end of the connecting rod 5 .

[0014] The working process of the above casing seal inner diameter inspection gauge:

[0015] (1) Adjust the depth screw 1 according to the sealing diameter position of the inspected workpiece, and adjust the lock nut 2 to fix t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com