Working platform lifting mechanism of full-automatic COG (Chip on Glass) binding machine

A technology of working platform and lifting mechanism, which is applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problems of poor stability of the working platform and low equipment bonding accuracy, and achieve the problems of poor stability, improved bonding accuracy, and stable lifting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The COG bonding machine is mainly to directly press the chip onto the glass. Among them, the working platform is the key part of the COG bonding machine. The platform needs to be lifted frequently during work. To ensure the stability of the platform and the smooth upgrade, the ordinary lifting mechanism cannot adapt high precision requirements.

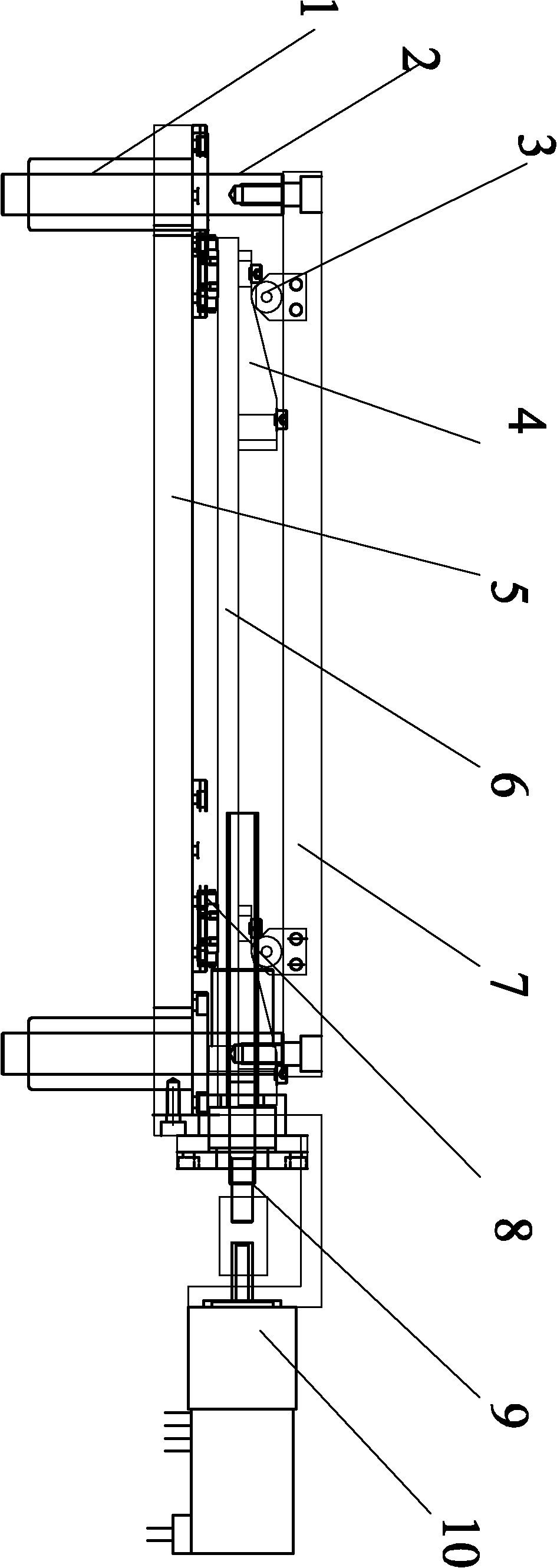

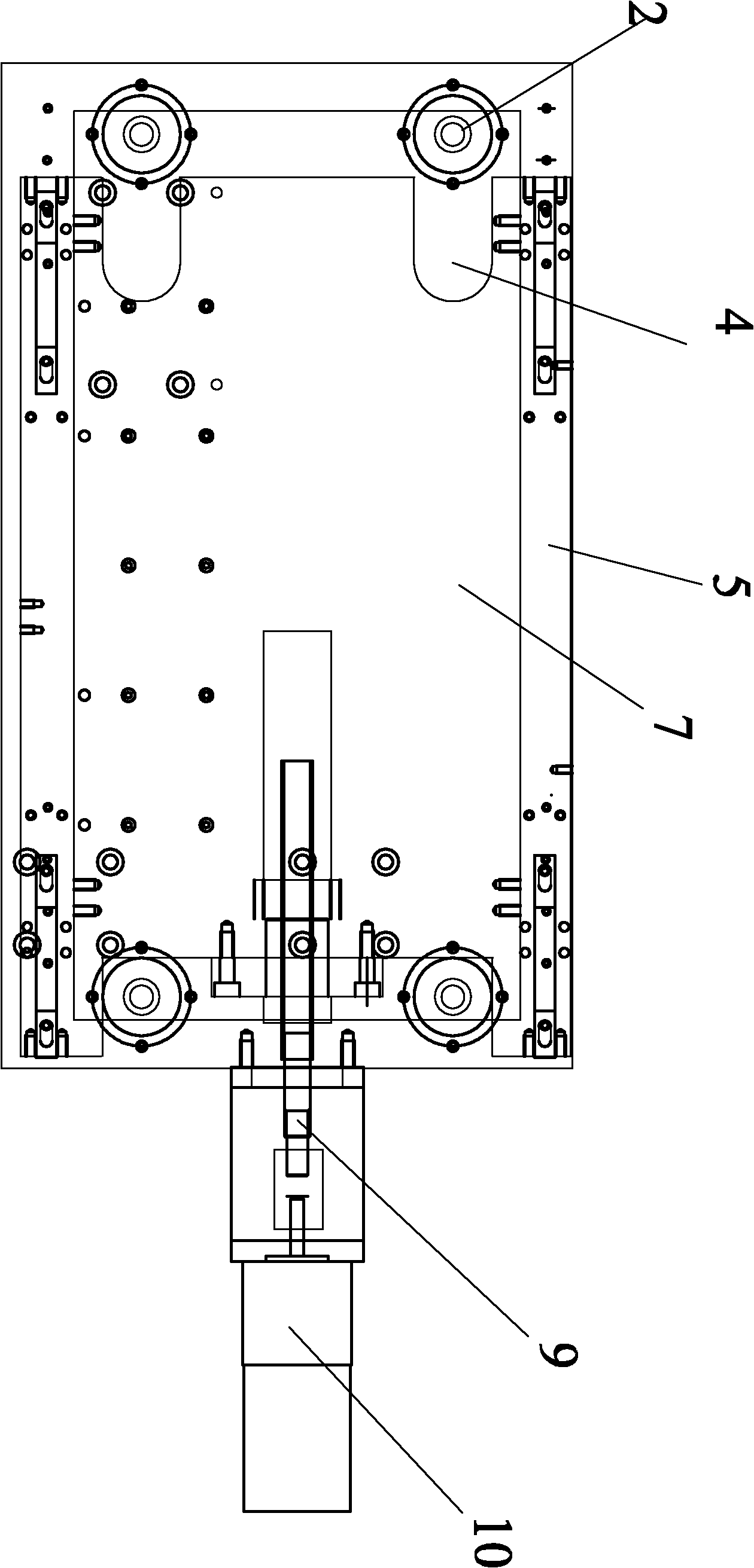

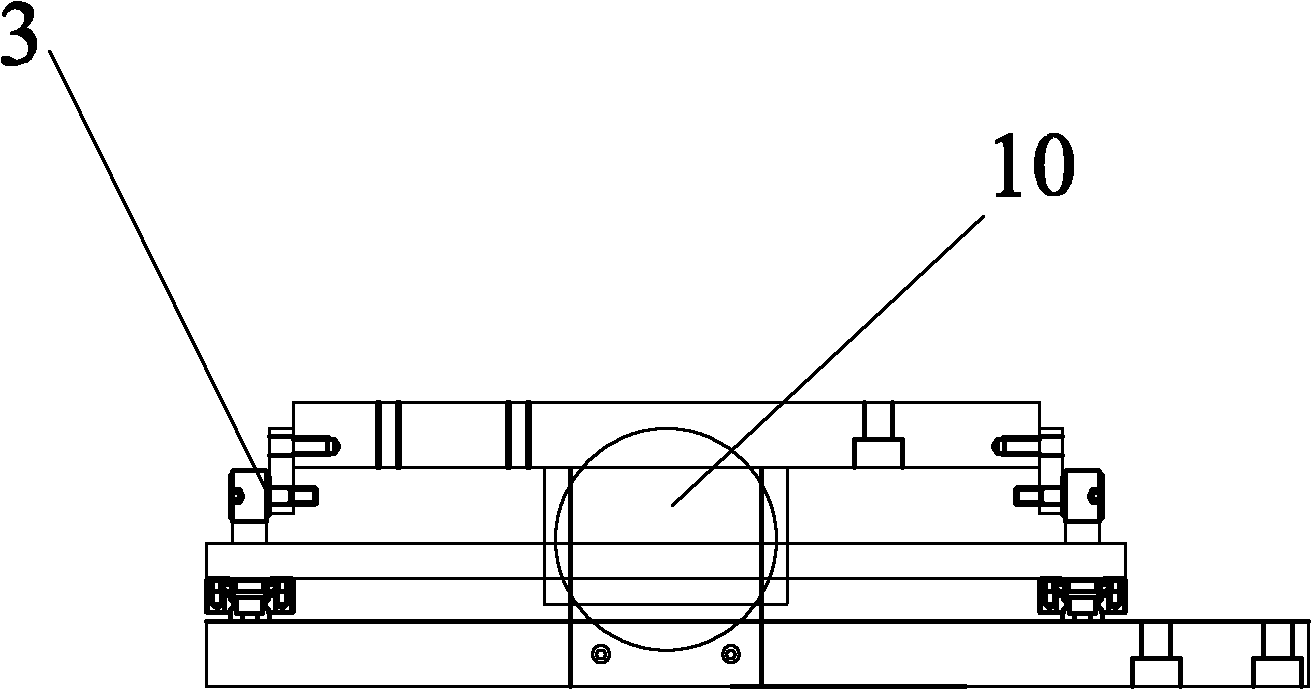

[0012] Such as Figure 1-3 As shown, the lifting mechanism of the working platform of the fully automatic COG bonding machine of the present invention includes a platform 7, and four guide shafts 2 and four bearings 3 are installed at the four corners of the platform. Below the platform 7, a translation plate 6 is installed next to the bearings. A precision lead screw 9 is installed at the middle position of the upper right end of the translation plate 6, and four corners of the translation plate 6 are also installed to match the four bearings on the platform 7. The wedge-shaped fast 4, the translation plate 6 drives the wedge...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap