Method for restraining torque ripple of permanent magnet motor based on direct torque control

A direct torque control, permanent magnet motor technology, applied in the direction of torque ripple control, etc., can solve the problems of increased manufacturing cost and limited reduction of motor torque ripple, to achieve the effect of increased manufacturing cost and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

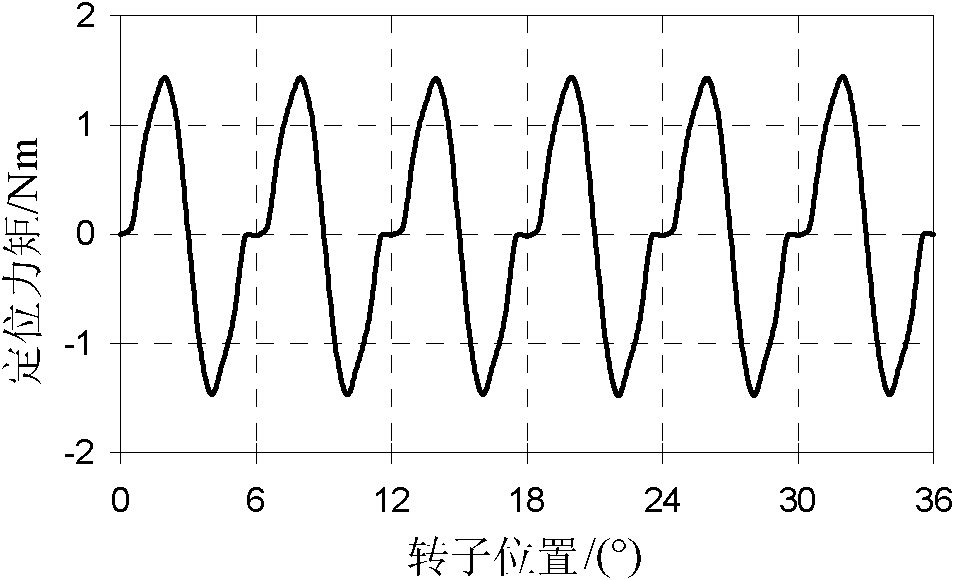

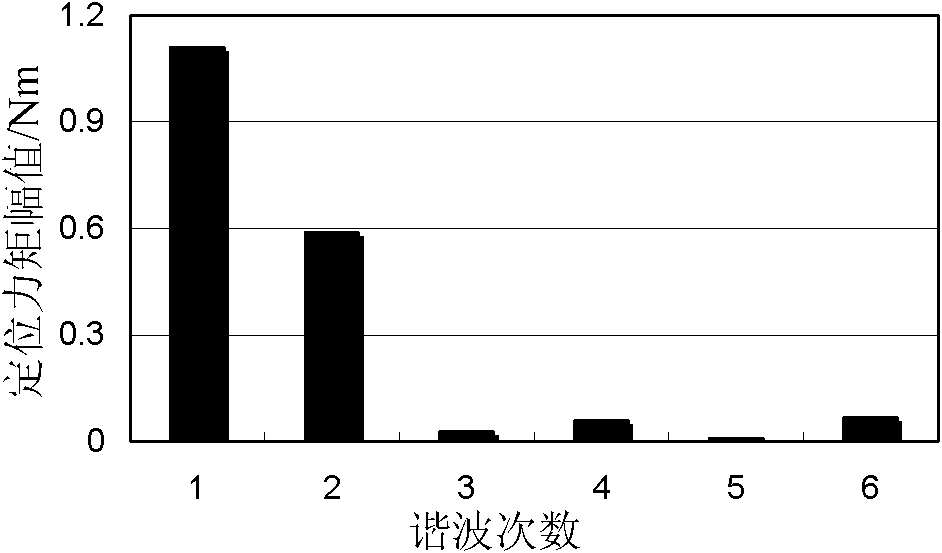

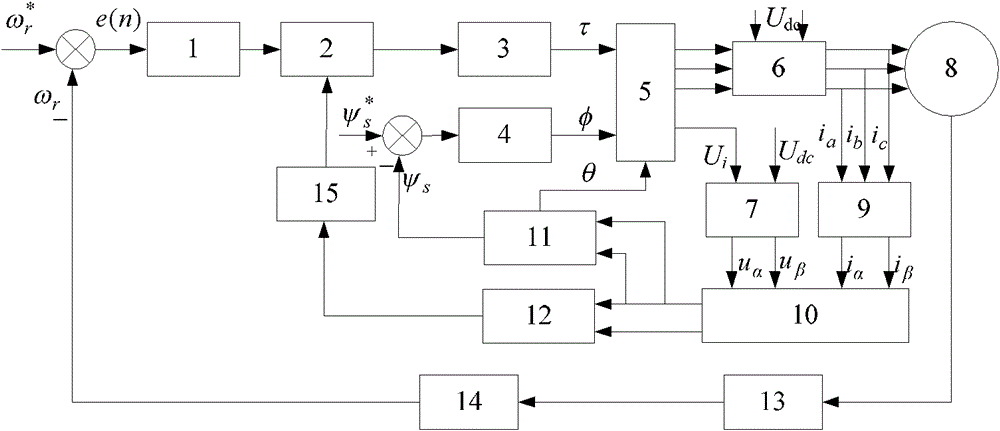

[0030] The present invention adopts a direct torque control strategy for the permanent magnet motor: a given electromagnetic torque is output through the PI regulator 1, and additional harmonic torque is directly injected on the basis of the given electromagnetic torque, so that the additional harmonic torque and positioning The fundamental wave component and high-order harmonic components in the torque are equal in amplitude and opposite in phase, and they cancel each other out to suppress torque ripple. Among them, the direct torque control strategy is a well-known technology in the field and will not be described in detail.

[0031] The present invention does not require any current adjustment and conversion between the stator and rotor coordinate syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com