Semi-circular tip jewelry molding machine

A jewelry forming machine and end technology, which can be applied to other household appliances, household appliances, applications, etc., can solve the problems of affecting the quality of finished products, low production efficiency, and small size of the monomer, so as to reduce production costs, high degree of automation, The effect of compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

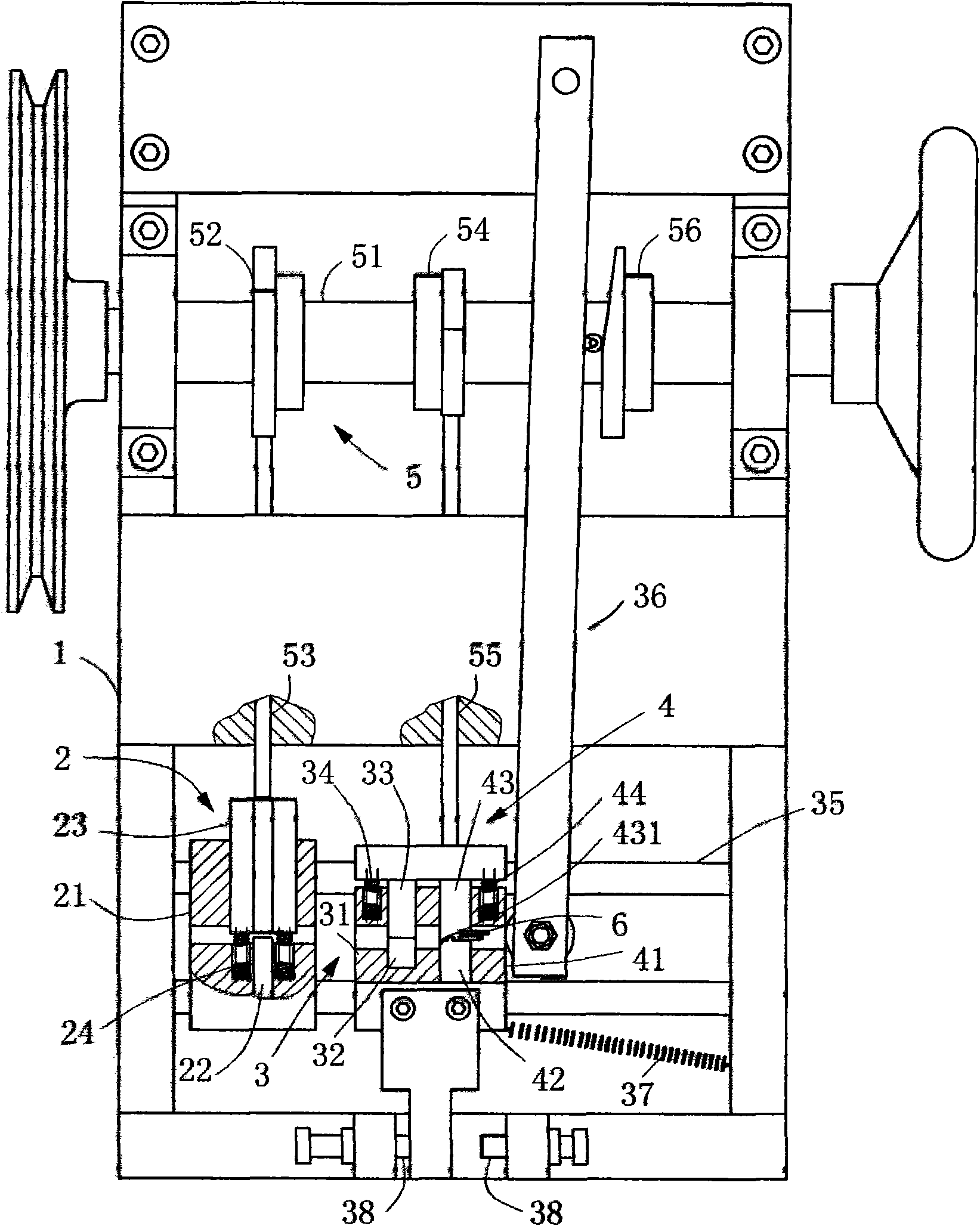

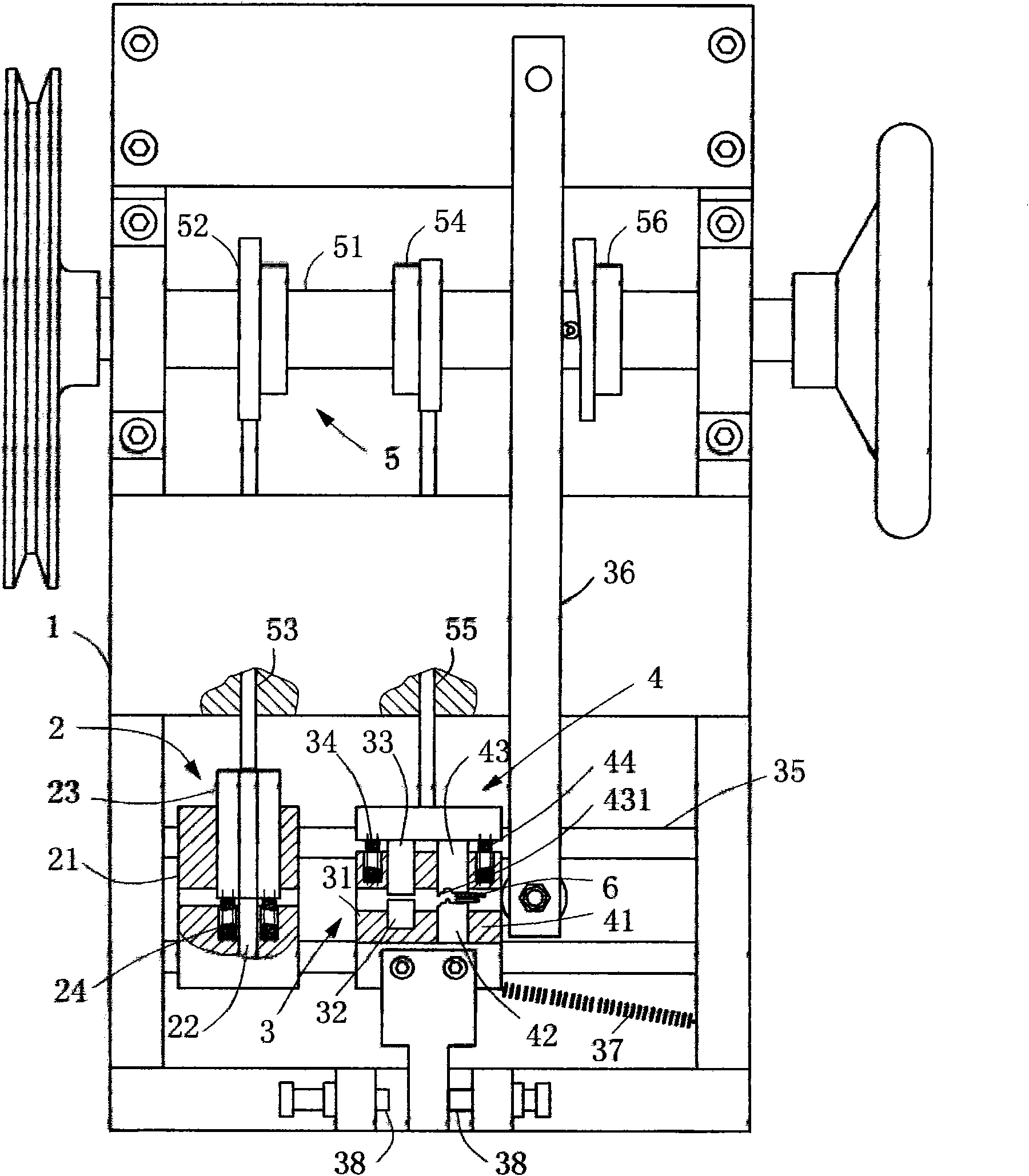

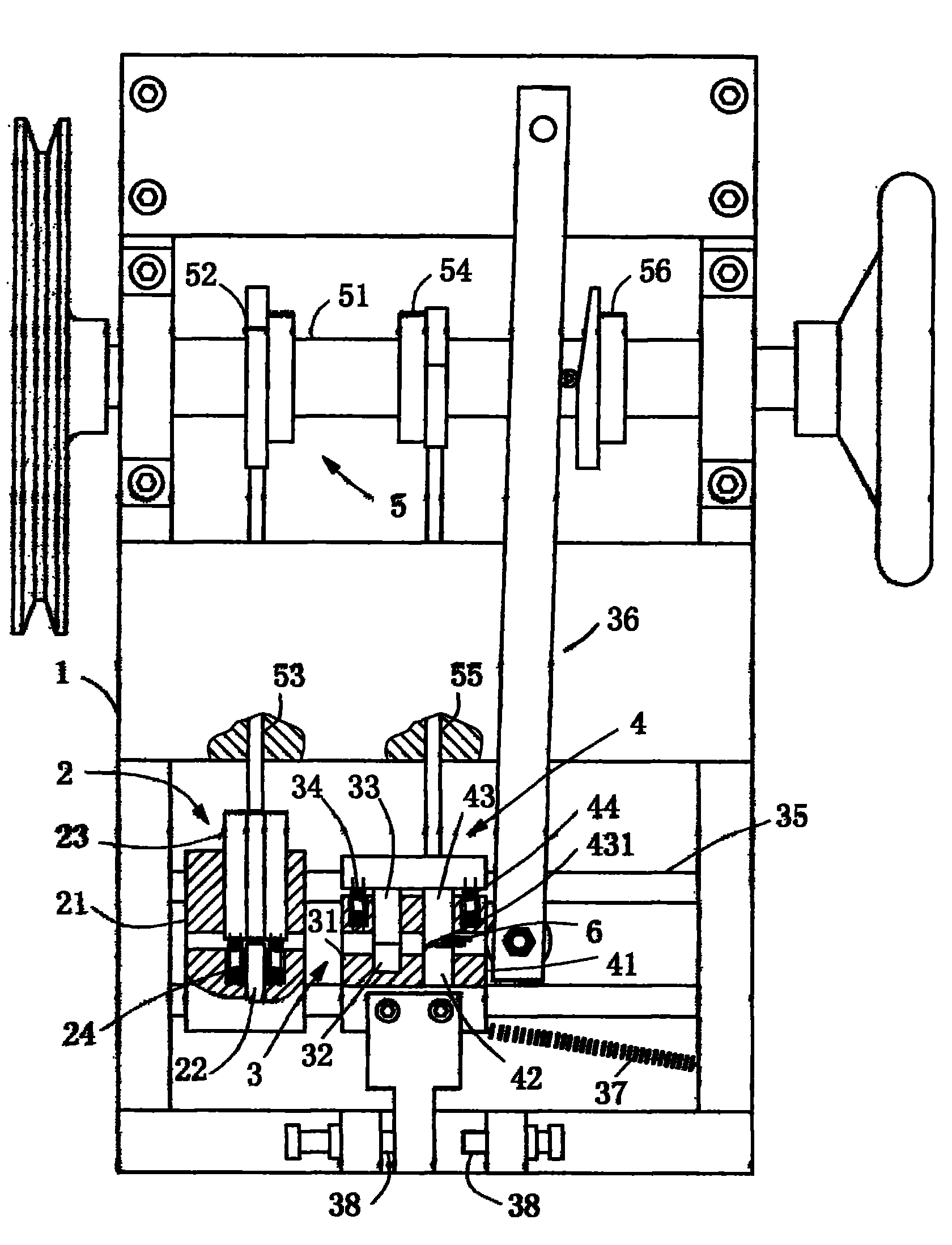

[0022] Such as figure 1 As shown, a semicircle end jewelry forming machine mainly includes a frame 1 and a feeding device and a cutting and forming device 4 sequentially installed on the frame 1 driven by a driving device 5 . Wherein, the feeding device is installed on the frame 1, and is used to gradually transport the wire to a downstream position; the cutting and forming device 4 is installed on the frame 1 and is positioned at the downstream of the feeding device, for The metal wire is cut and formed into a semicircular end; the driving device 5 is used to drive the feeding device and the cutting and forming device 4 to operate periodically.

[0023] The feeding device includes a first clamping mechanism 2 and a second clamping mechanism 3 for clamping or loosening the wire. The first clamping mechanism 2 is installed on the frame 1, and the first clamping mechanism 2 mainly includes a first clamping seat 21, a first fixed chuck 22, a first moving chuck 23 and a first Re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com