Disposable integrated coarse-fine boring tool

A boring tool and discarding technology, which is applied in the field of rough and fine integrated discarding boring tools, can solve the problems of low production efficiency, long processing time, manual intervention, etc., to improve production efficiency, reduce processing procedures, and prevent winding Effect

Inactive Publication Date: 2011-06-15

CHANGZHOU TENGLONG AUTO PARTS CO LTD

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This traditional processing method meets the high-precision hole processing requirements of stainless steel and non-ferrous metal parts commonly used in the auto parts and precision instrumentation industries. Its disadvantages are that there are many procedures, long processing time, and manual intervention , the processing is discontinuous and the production efficiency is relatively low, and the advanced nature of flexible processing equipment cannot be brought into play

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

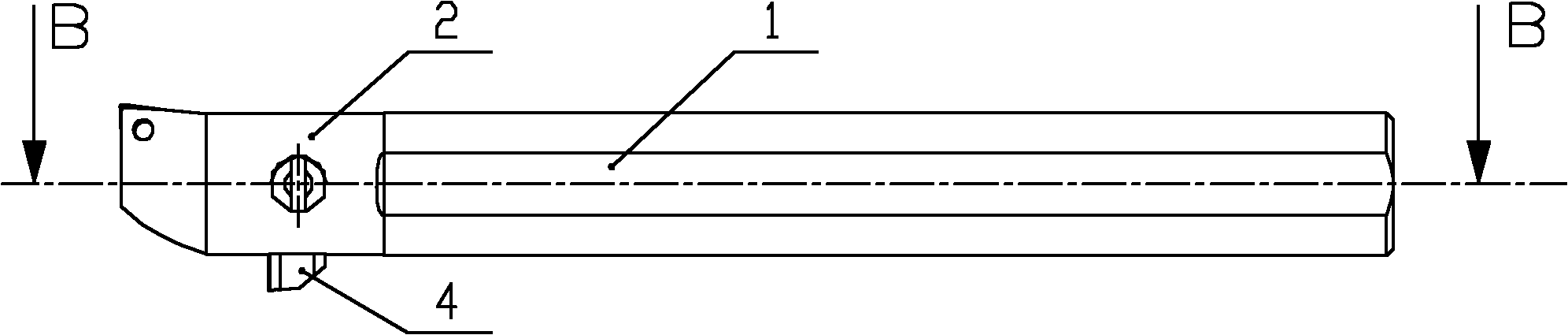

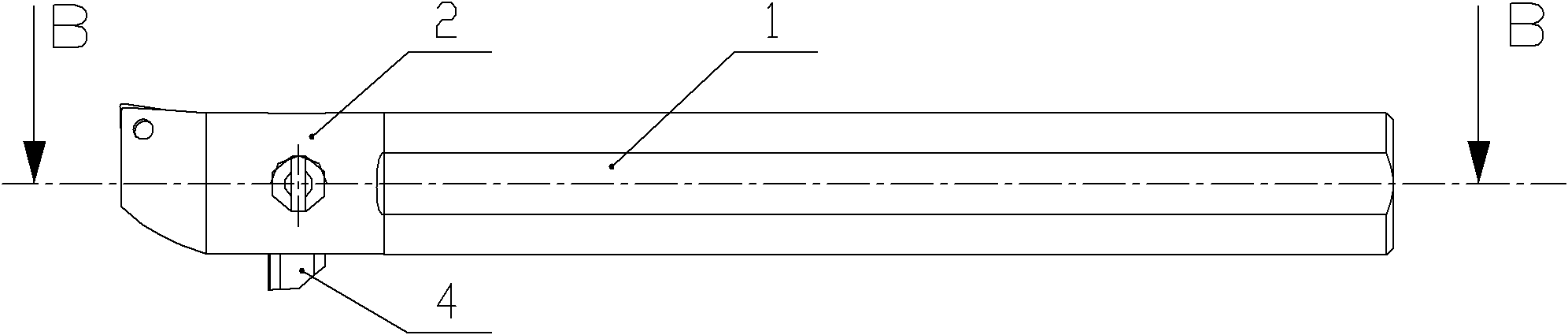

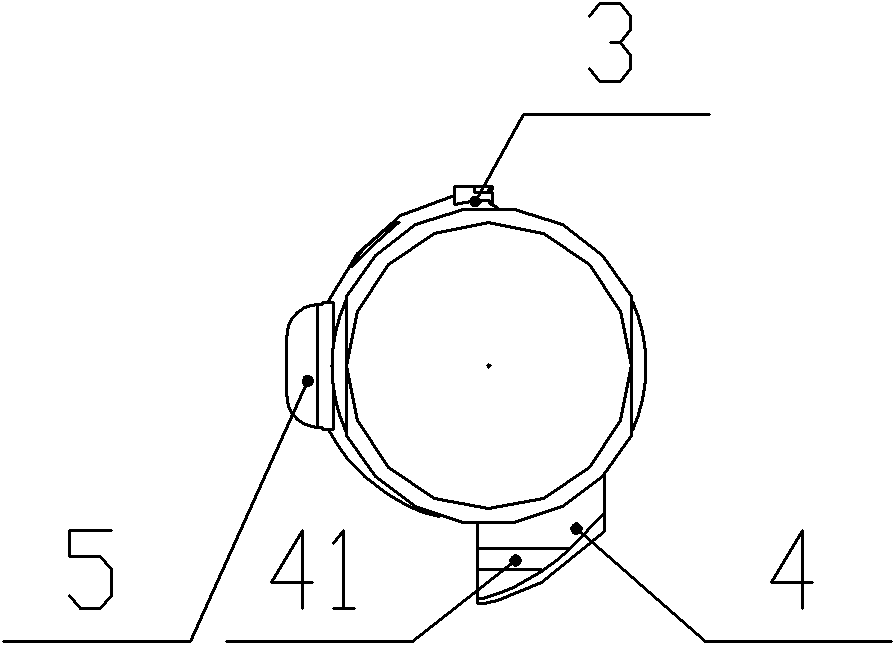

The invention discloses a disposable integrated coarse-fine boring tool comprising a tool handle and a tool bit integrated with the tool handle. A fine boring blade is detachably fixed on the front end of the tool bit; a coarse boring tool bit is detachably fixed on the middle-rear part of the tool bit; the points of both the fine boring blade and the coarse boring tool bit are respectively arranged on two sides of the center of the tool bit; and a chip breaking groove is arranged on the coarse boring tool bit. A coarse boring tool and a fine boring tool are integrated into a whole, thus the requirement of one tool for coarse boring and fine boring is met, and the problems of many processing substeps and low efficiency existing in the traditional processing method are solved, and more importantly, the requirement of high-precision holes and the flexible production requirement of mass parts for processing efficiency and IE engineering are met.

Description

Rough and fine integrated discarded boring tool technical field The invention relates to the field of mechanical processing, in particular to a rough-finish integrated discarding boring tool for continuous and high-efficiency rough-finish boring processing. Background technique For a long time, continuous and efficient mechanical roughing and finishing has been the processing concept pursued in the field of metal processing. For the boring processing with large quantities and high-precision hole requirements, there are two common processing methods: one is to use the combination of rough and fine boring, but the rough and fine boring tools are divided, that is, two tools are used for processing , so that continuity and efficiency cannot be achieved. Especially under the condition that the space conditions of the equipment are limited and several cutting tools cannot be installed at the same time, this traditional method cannot be used; It is used for finishing turning to...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23B27/00B23B27/16B23B27/22

Inventor 葛恒超

Owner CHANGZHOU TENGLONG AUTO PARTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com