Deforming grid device for ceramic brick production

A ceramic tile and grid technology, applied in the field of deformed grid devices, can solve the problems of broken pattern effect, interruption, unnatural bending, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

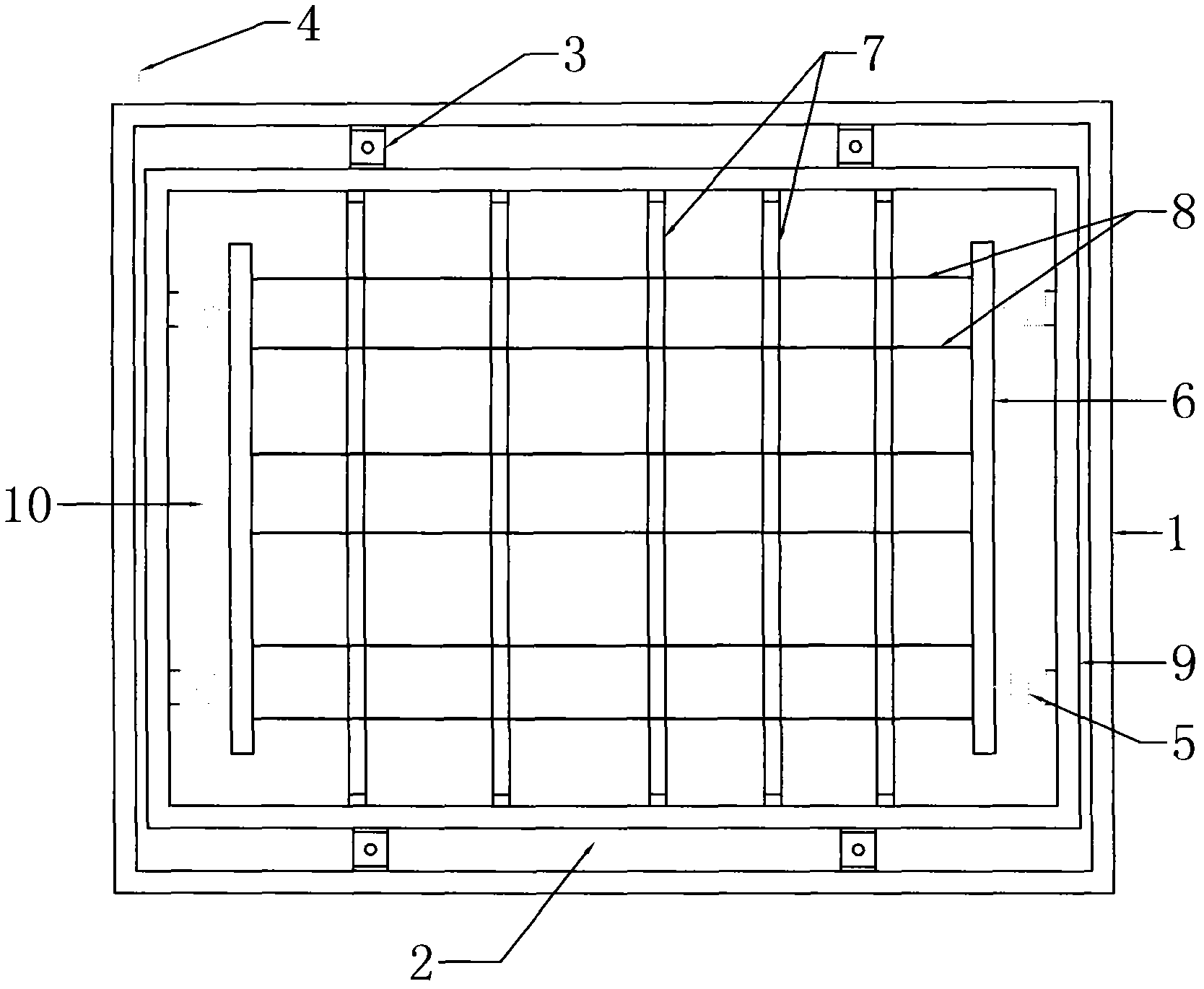

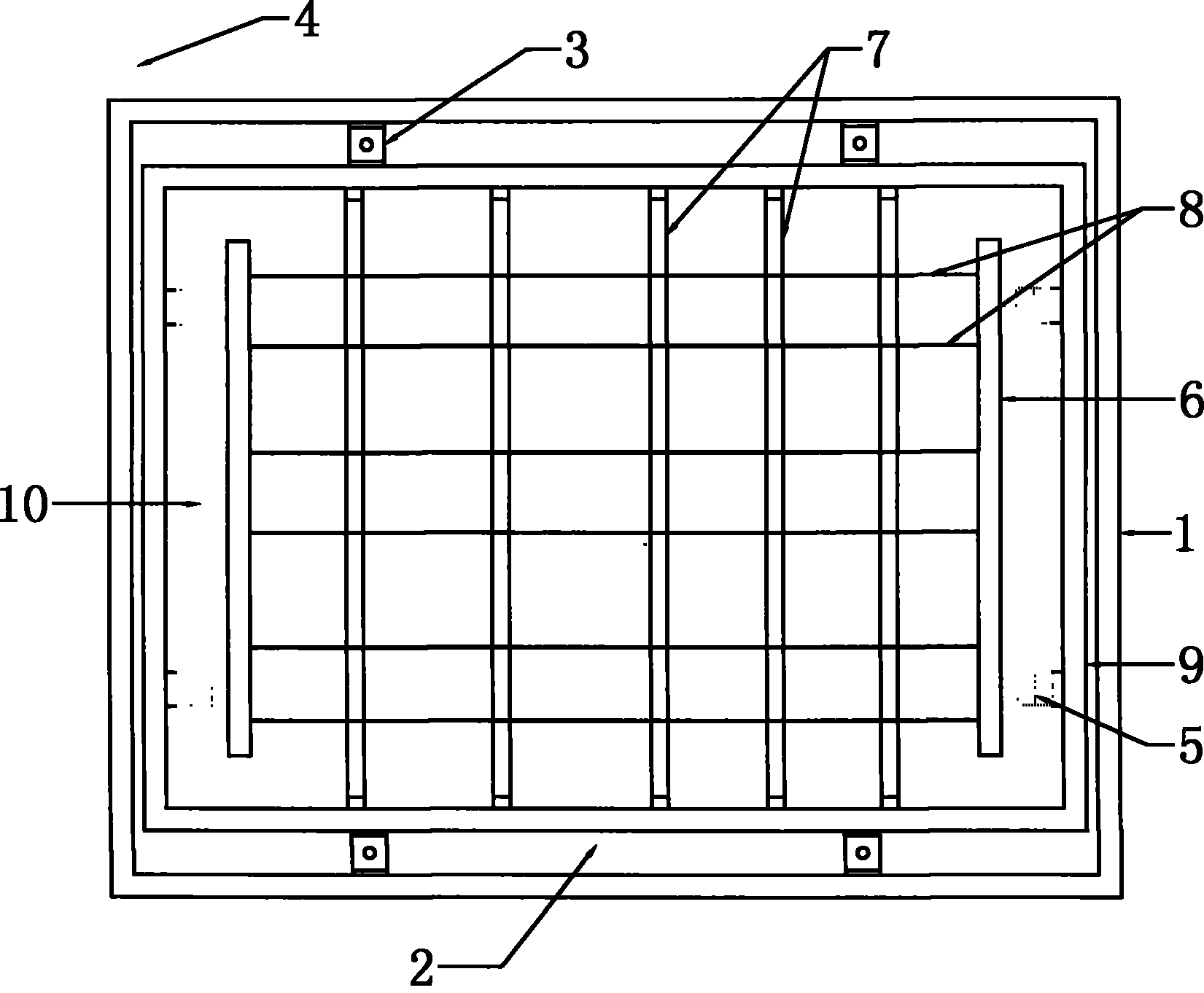

[0014] Attached below figure 1 To further illustrate the present invention, the preferred embodiment of the present invention is: the deformed grid device described in this embodiment includes an outer frame 1, and the outer frame 1 is assembled on the frame through a horizontal moving element 4. The horizontal moving element 4 of the example is a cylinder, and the outer frame 1 after assembly is provided with a deformed grille assembly 2, and the deformed grille assembly 2 includes a vertical drive element 3, a deformed sheet 8, an inner frame 9, and a deformer 10 , wherein, the inner frame 9 is assembled in the outer frame 1 through the vertical driving element 3, and the vertical driving element 3 can be a cylinder, an oil cylinder, a crank connecting rod or a rack and pinion. The vertical driving element 3 of the present embodiment is a cylinder, and the cylinder block is installed in the outer frame 1. The installed cylinder piston rod is connected with the inner frame 9....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com