A blend of ceramic pigment glaze and its production method, imitation stone glazed tile and its production method

A technology for ceramic pigments and production methods, applied in the fields of blended ceramic pigment glaze and imitation stone glazed tiles, can solve the problems of intensified loss of details, loss of details, and distance between stones, so as to achieve natural and smooth lines, improve decorative effects, and clear veins. detailed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] The present embodiment provides a kind of imitation stone material glazed tile, and it is produced through the following steps:

[0082] S1: Raw materials are used to prepare slurry through batching and ball milling, and after iron removal, sieving, aging, spray tower milling, and then sieving to obtain a blank; wherein, the blank formula is the green body formula of ordinary glazed ceramics;

[0083] S2: Press and shape the billet by a press to form a green body;

[0084] S3: Transporting the green body to a drying kiln for drying to obtain a dried green body;

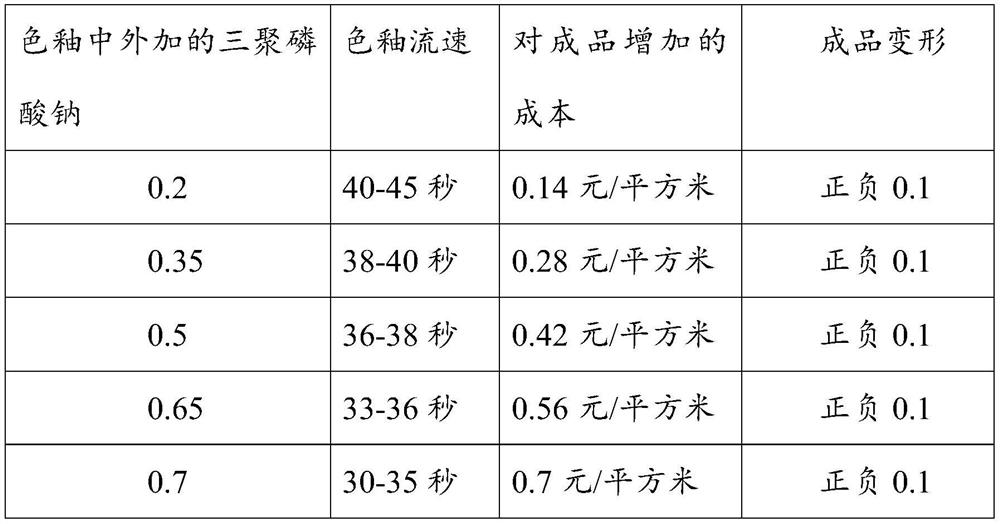

[0085]S4: Adjust the flow rate of the colored glaze to 45-50s by adding sodium tripolyphosphate and debonding agent on the basis of the base glaze of the colored glaze, and then import it into the fluid colored glaze container; the amount of added sodium tripolyphosphate is according to 0.2 to 0.8 parts by weight, and the amount of the additional debonding agent is 5 to 30 parts by weight; meanwhile, the base ...

Embodiment 2

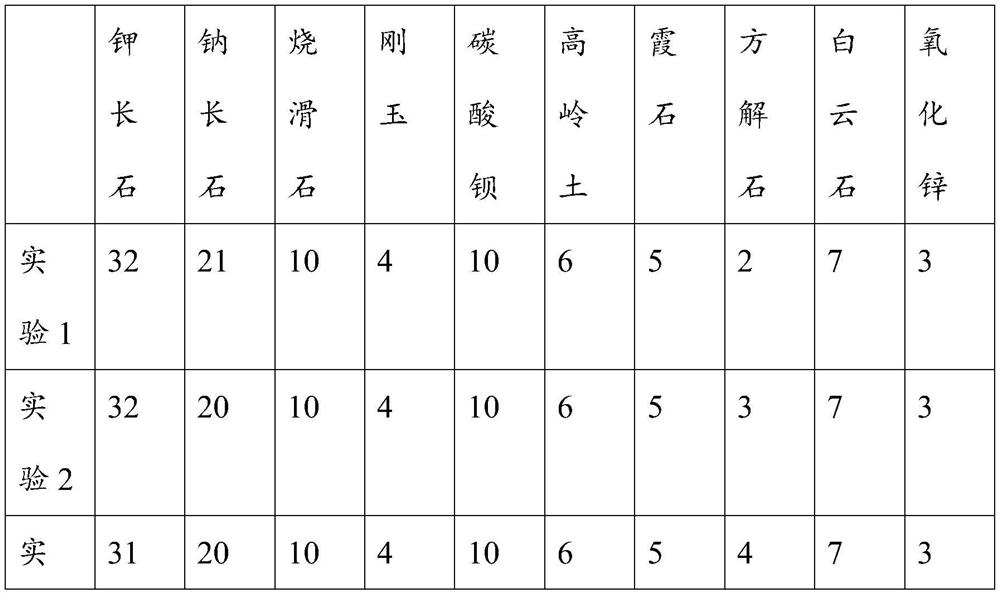

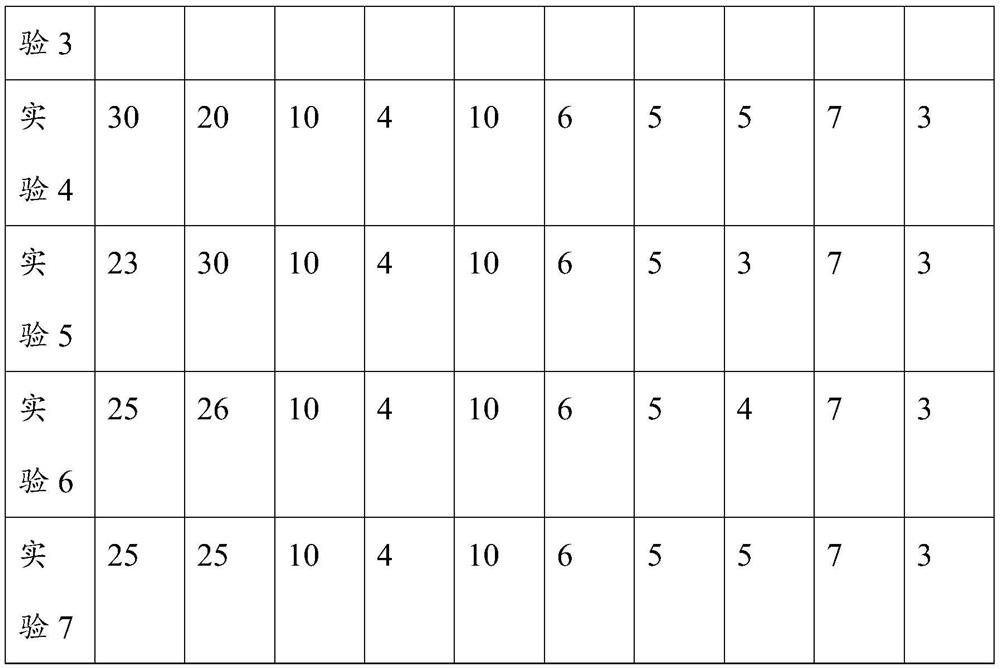

[0092] This embodiment provides a kind of imitation stone material glazed tile, the difference of its preparation method and the preparation method that embodiment 1 provides is:

[0093] In step S4, the flow rate of the color glaze is 48s, the amount of added sodium tripolyphosphate is 0.35 parts by weight, and the amount of added debonding agent is 15 parts by weight; meanwhile, The base glaze of the color glaze includes: potassium feldspar: 31 parts; albite feldspar: 20 parts; burnt talc: 10 parts; corundum: 4 parts; barium carbonate: 10 parts; kaolin: 6 parts; nepheline: 5 parts; calcite: 4 parts ; Dolomite: 7 parts; Zinc oxide: 3 parts; Sodium tripolyphosphate: 0.35 parts; Carboxymethylcellulose sodium C50A: 0.15 parts; Sodium humate: 0.2 parts;

[0094] In step S5, the top glaze includes Lidejia top glaze LM2042: 97 parts; zirconium silicate 14 parts; dolomite powder: 5 parts; zinc oxide: 3 parts; parts; sodium carboxymethylcellulose C50A: 0.15 parts, sodium humate: 0.2...

Embodiment 3

[0097] This embodiment provides a kind of imitation stone material glazed tile, the difference of its preparation method and the preparation method that embodiment 1 provides is:

[0098] In step S4, the flow rate of the color glaze is 48s, the amount of added sodium tripolyphosphate is 0.8 parts by weight, and the amount of added debonding agent is 30 parts by weight; meanwhile, The base glaze of colored glaze includes: potassium feldspar: 32 parts; albite feldspar: 30 parts; burnt talc: 10 parts; corundum: 4 parts; barium carbonate: 12 parts; kaolin: 8 parts; nepheline: 7 parts; calcite: 5 parts ; Dolomite: 20 parts; Zinc oxide: 4 parts; Sodium tripolyphosphate: 0.8 parts; Carboxymethylcellulose sodium C50A: 0.2 parts; Sodium humate: 0.3 parts;

[0099] In step S5, the surface glaze includes Lidejia surface glaze LM2042: 100 parts; zirconium silicate: 15 parts; dolomite powder: 5 parts; zinc oxide: 4 parts; ~0.8 parts; sodium carboxymethylcellulose C50A: 0.15 parts, sodium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com