Inkjet ceramic tile imitating natural stone texture and production method thereof

A technology of imitating natural stone and production methods, applied in ceramic molding machines, covering/lining, construction, etc., can solve the problems of the limitation of personalized design concepts, the low level of imitation of natural stone texture, etc., to achieve natural and smooth texture, Rich and vivid texture changes, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

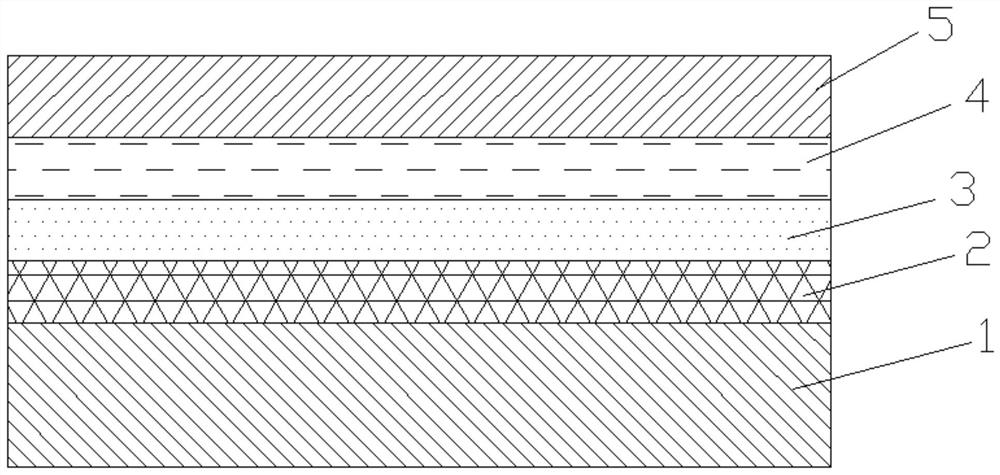

[0024] Such as figure 1 and figure 2 In conjunction with shown, a kind of production method of the ink-jet ceramic tile imitating natural stone texture, its steps are as follows:

[0025] 1) The ceramic raw materials are wet-mixed and ball-milled, and the basic slurry is made after sieving;

[0026] 2) Add colorants of different colors to the basic slurry respectively to make ceramic slurry of different colors, and store them in slurry storage tanks respectively;

[0027] 3) Connect the slurry inlet of the spray gun to the outlet of the slurry storage tank, and spray ceramic slurry of different colors onto the surface glaze layer of the adobe through the spray gun to form an inkjet printing pattern decorative layer;

[0028] 4) When the slurry is half dry, sprinkle mica flakes on the surface of the inkjet printing pattern decoration layer;

[0029] The ceramic slurry is sprayed onto the adobe, and its thickness is controlled to be 1-10 mm.

[0030] In step 1), the specifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com