Subassembly device of integrated automobile accelerator

A technology of accelerators and sub-assemblies, which is applied in the layout of power plant control mechanisms, vehicle components, transportation and packaging, etc., can solve the problems of complex structure, easy to wear and break wire ropes, low balance and reliability, and achieve the structure of the device. Simple, save processing time, and improve the effect of load efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

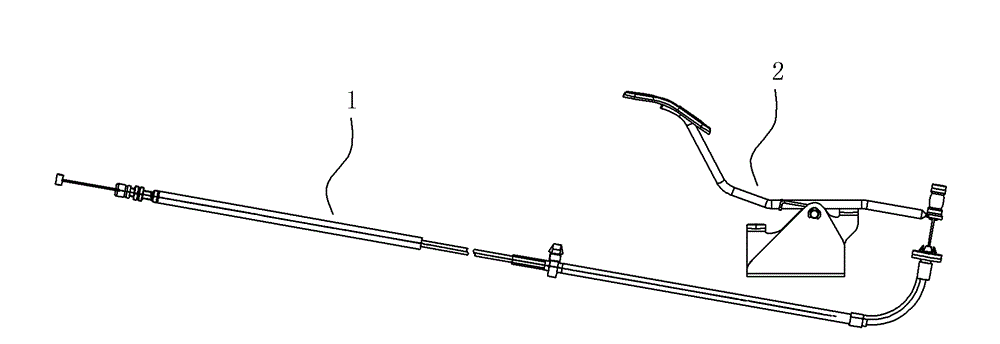

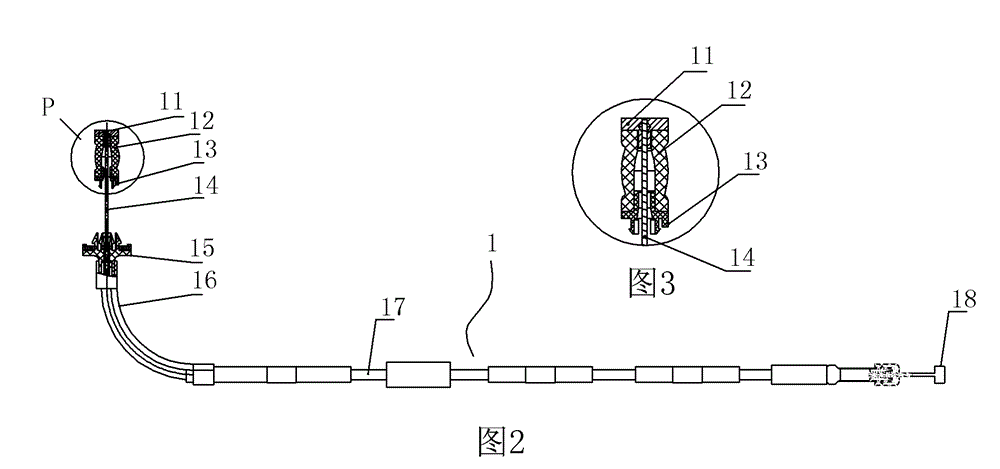

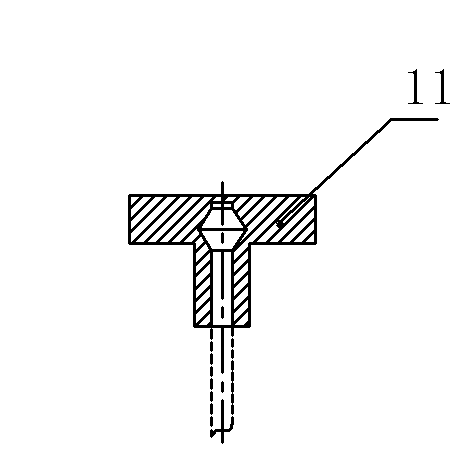

[0027] An integrated automotive accelerator subassembly (see Figure 1 to Figure 8-3 ), including accelerator cable assembly 1 and accelerator pedal assembly 2.

[0028] The accelerator pedal assembly includes a pedal rod assembly 21, a bracket welding piece 23, a return spring 22, a bushing 24 and a back ring 25, and the pedal rod assembly 21 of the accelerator pedal assembly 2 is mainly composed of a pedal rod 213 1. A pedal 214 welded at one end of the pedal rod and a rotating pin 212 fixed at the middle of the pedal rod. The other end of the pedal rod of the accelerator pedal assembly 2 is formed by stamping to cooperate with the nylon joint 13 of the accelerator cable assembly. The circular cable fixing ring 211, the pedal rod assembly 21 is installed on the bracket welding part 23 through the rotating pin shaft 212, and is positioned by the bushing 24 and the retaining ring 25, and the bracket welding part is provided with a spring limiting Position rod 234, front limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com