Preparation method of zinc oxide nano linear array

A technology of zinc oxide nanowires and arrays, which is applied in the field of materials, can solve the problem that it is difficult to ensure the repeatability of zinc oxide nanowire arrays, the solution concentration of zinc oxide nanowire arrays is sensitive, and the growth density and solution concentration of zinc oxide nanowire arrays do not exist. Functional relations etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

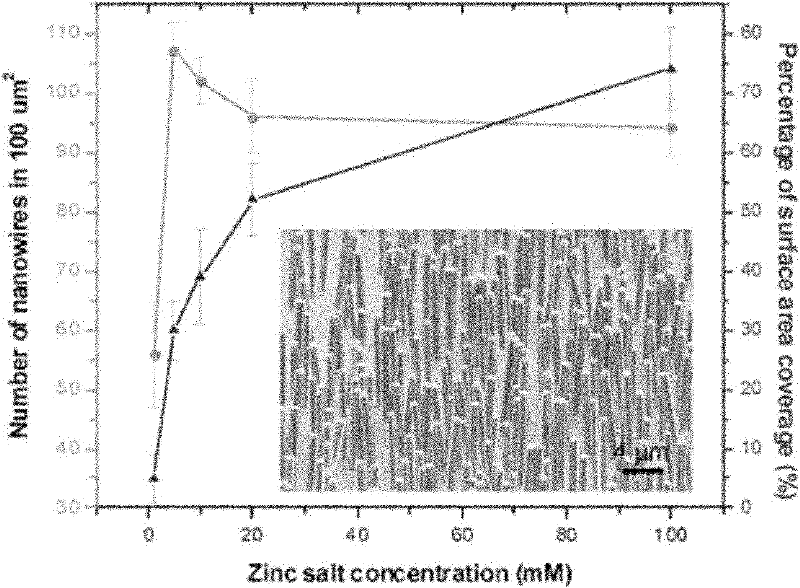

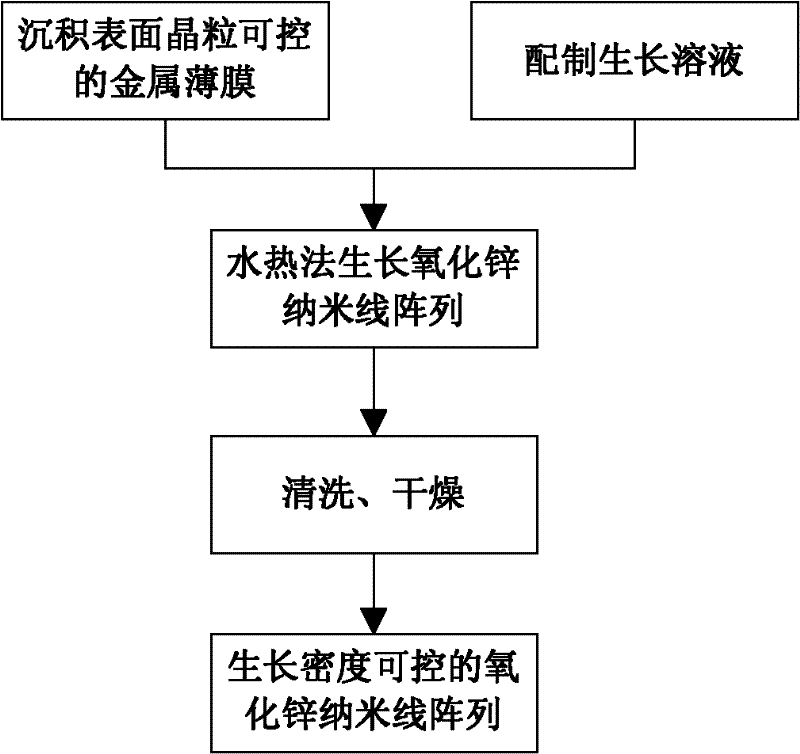

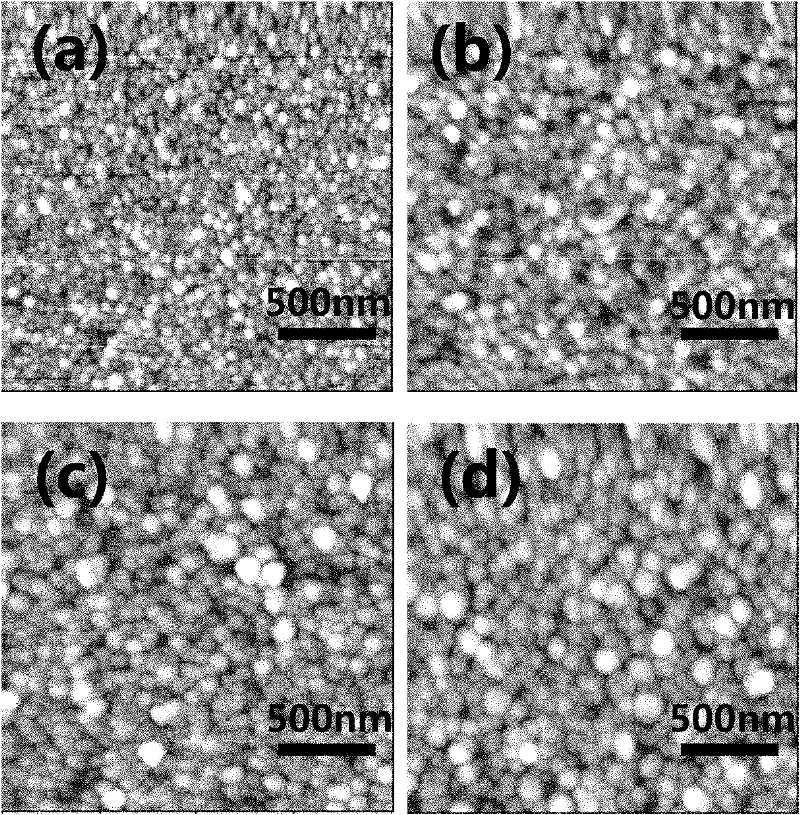

[0023] Gold films with four different surface grains were deposited on the silicon substrate by using the magnetron sputtering process. The sputtering process conditions were: argon atmosphere 1Pa, power 32W, and sputtering time were 5 minutes, 10 minutes, 15 minutes and 20 minutes respectively. Minutes, the atomic force microscope photographs of the obtained four kinds of gold films with different surface grains are as follows: image 3 (a), (b), (c), (d) shown. The four kinds of gold films were grown in the prepared growth solution by facing down. The growth solution was prepared with equimolar amounts of zinc nitrate and hexamethylenetetramine, and the concentration was 0.05mol L -1 , the temperature of the growth solution is controlled to be 75 degrees, and the growth time is 24 hours. ZnO nanowire arrays grown as Figure 4 (a), (b), (c), (d) shown. The relationship between the growth density of ZnO nanowire arrays grown under such conditions and the grain radius is as ...

Embodiment 2

[0025] Gold films with four different surface grains were deposited on the silicon substrate by using the magnetron sputtering process. The sputtering process conditions were: argon atmosphere 1Pa, power 32W, and sputtering time were 5 minutes, 10 minutes, 15 minutes and 20 minutes respectively. Minutes, the atomic force microscope photographs of the obtained four kinds of gold films with different surface grains are as follows: image 3 (a), (b), (c), (d) shown. The four kinds of gold films were grown in the prepared growth solution by facing down. The growth solution was prepared with equimolar amounts of zinc nitrate and hexamethylenetetramine, and the concentration was 0.02mol L -1 , the temperature of the growth solution is controlled to be 75 degrees, and the growth time is 24 hours. The relationship between the growth density of ZnO nanowire arrays grown under such conditions and the grain radius is as follows: Figure 5 (b) shown.

Embodiment 3

[0027] Gold films with four different surface grains were deposited on the silicon substrate by using the magnetron sputtering process. The sputtering process conditions were: argon atmosphere 1Pa, power 32W, and sputtering time were 5 minutes, 10 minutes, 15 minutes and 20 minutes respectively. Minutes, the atomic force microscope photographs of the obtained four kinds of gold films with different surface grains are as follows: image 3 (a), (b), (c), (d) shown. The four kinds of gold films were grown in the prepared growth solution by facing down. The growth solution was prepared with equimolar amounts of zinc nitrate and hexamethylenetetramine, and the concentration was 0.01mol L -1 , the temperature of the growth solution is controlled to be 75 degrees, and the growth time is 24 hours. The relationship between the growth density of ZnO nanowire arrays grown under such conditions and the grain radius is as follows: Figure 5 (c) shown.

[0028] Depend on Figure 5 It ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com