Tension cover of spinning bobbin

A bobbin and tension technology, applied in textiles and papermaking, etc., can solve the problems such as the adverse effects of the excellent properties of raw silk and the complicated weaving process, and achieve the effect of simple structure and convenient setting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Tensioners are known in the technical field of textile machine accessories, however these are designed exclusively for mounting on warp beams. The tension cover provided by the present invention is specially used on the textile bobbin to solve the difficult problem of sticking when raw silk is used as raw material for weaving, so that the production of raw silk as raw material can be carried out smoothly.

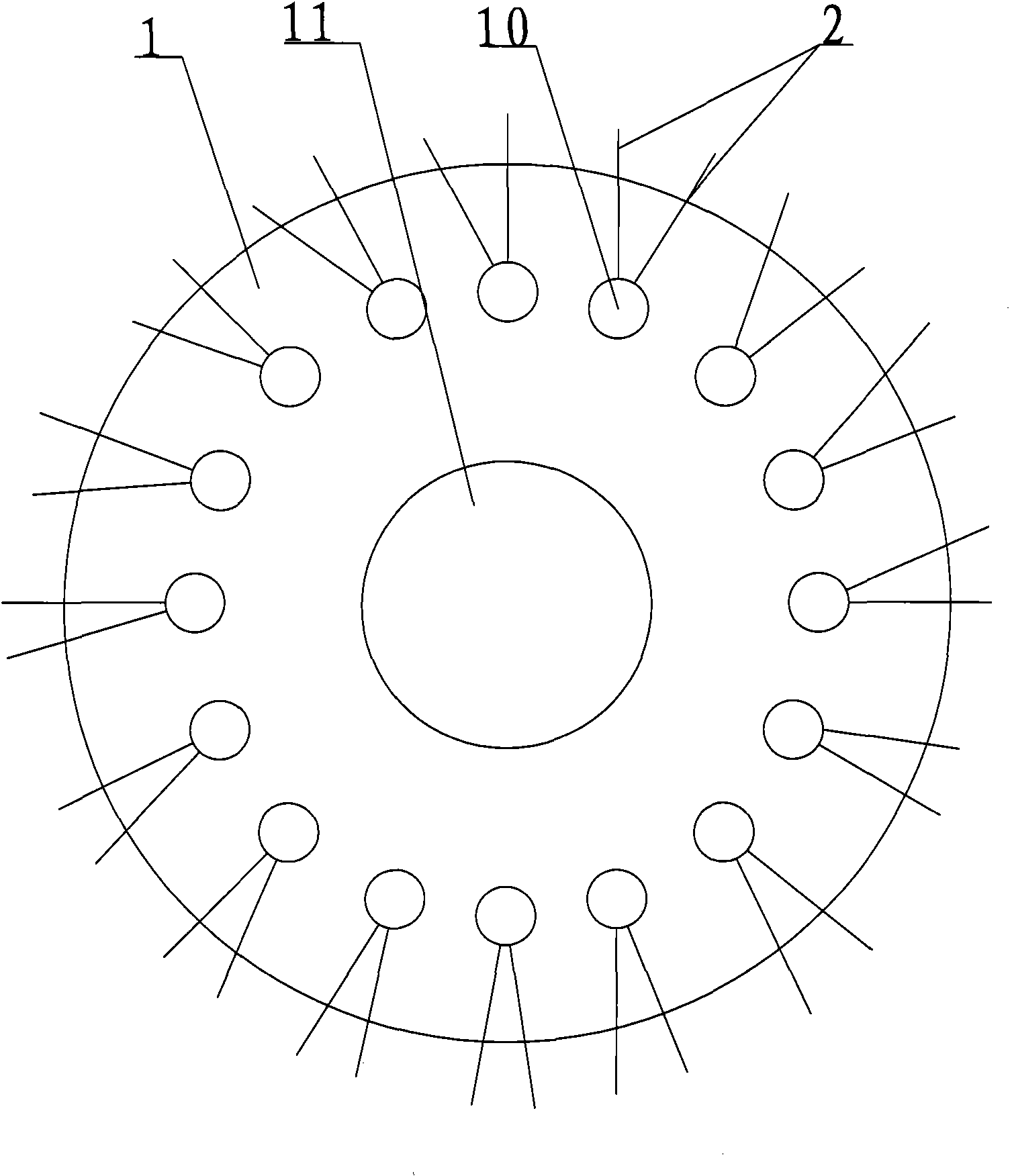

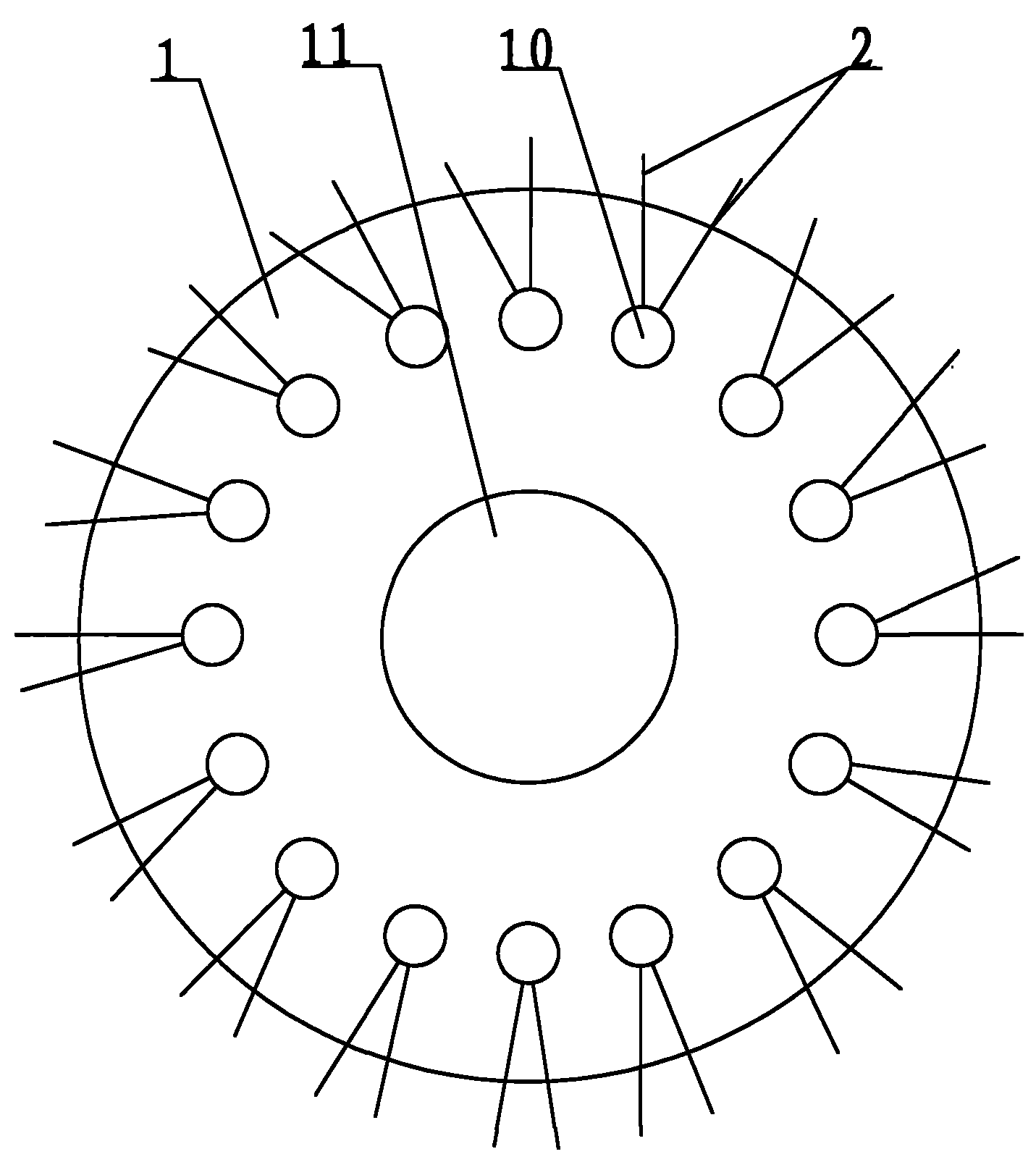

[0016] Such as figure 1 As shown, the textile package tension cover according to this embodiment includes a circular cover body 1 and resistance wires 2 uniformly distributed along the circumferential direction of the cover body 1 . The center of the cover body 1 is provided with a fixing hole 11, through which the cover body 1 can be fixed to the end of the textile bobbin, or the cover body 1 can be solid, and at this time it can be fixed on one side of the cover body 1 Several steel wire feet are connected, and the fixing of the cover body 1 and the end of the tex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com